Sandwich-structure high-energy-storage low-conductivity polymer-based composite film manufacturing method

A composite thin film, low conductivity technology, applied in the direction of circuits, capacitors, electrical components, etc., can solve the problems of limiting dielectric constant and breakdown strength, restricting overall performance, large dielectric loss, etc., to achieve favorable breakdown strength , Improve overall performance, improve the effect of breakdown strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

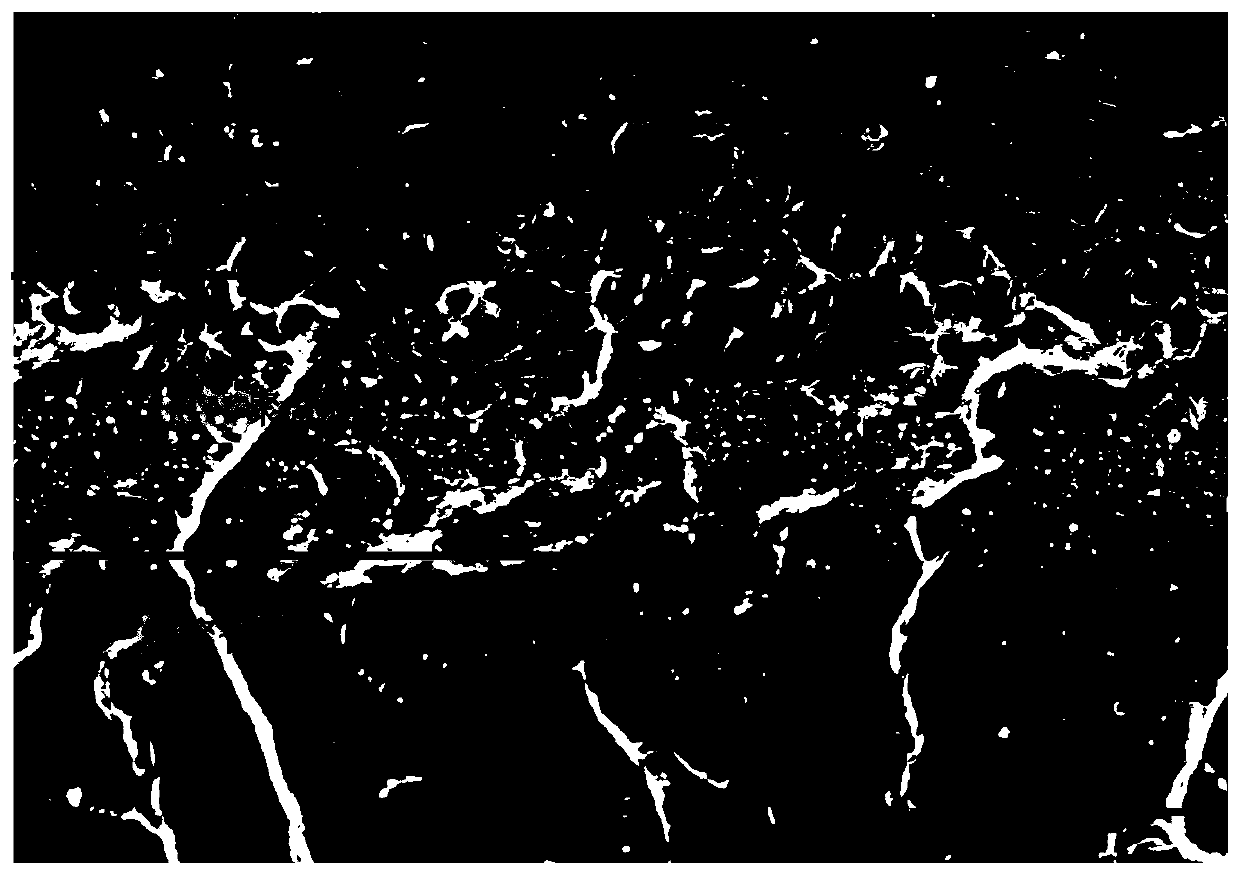

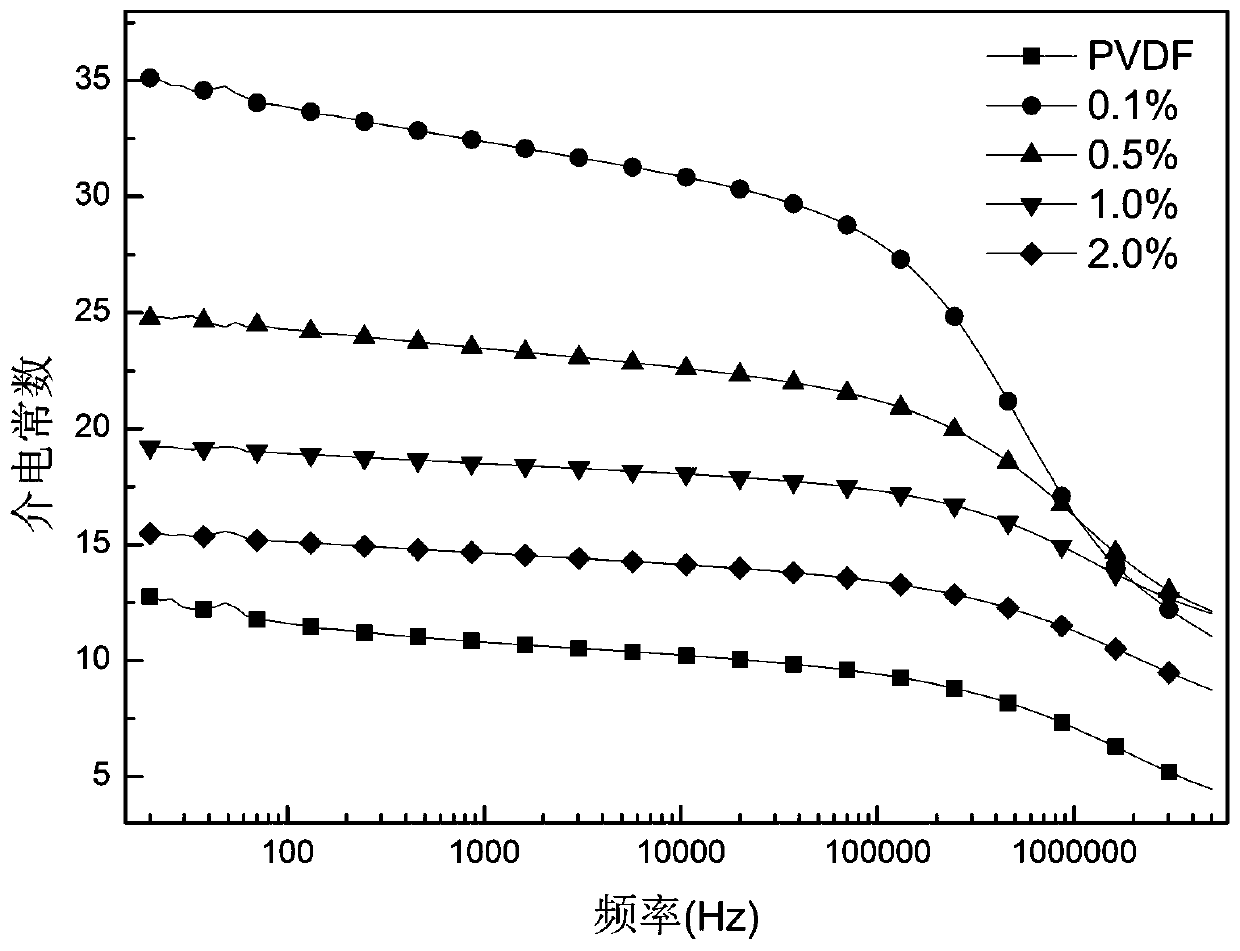

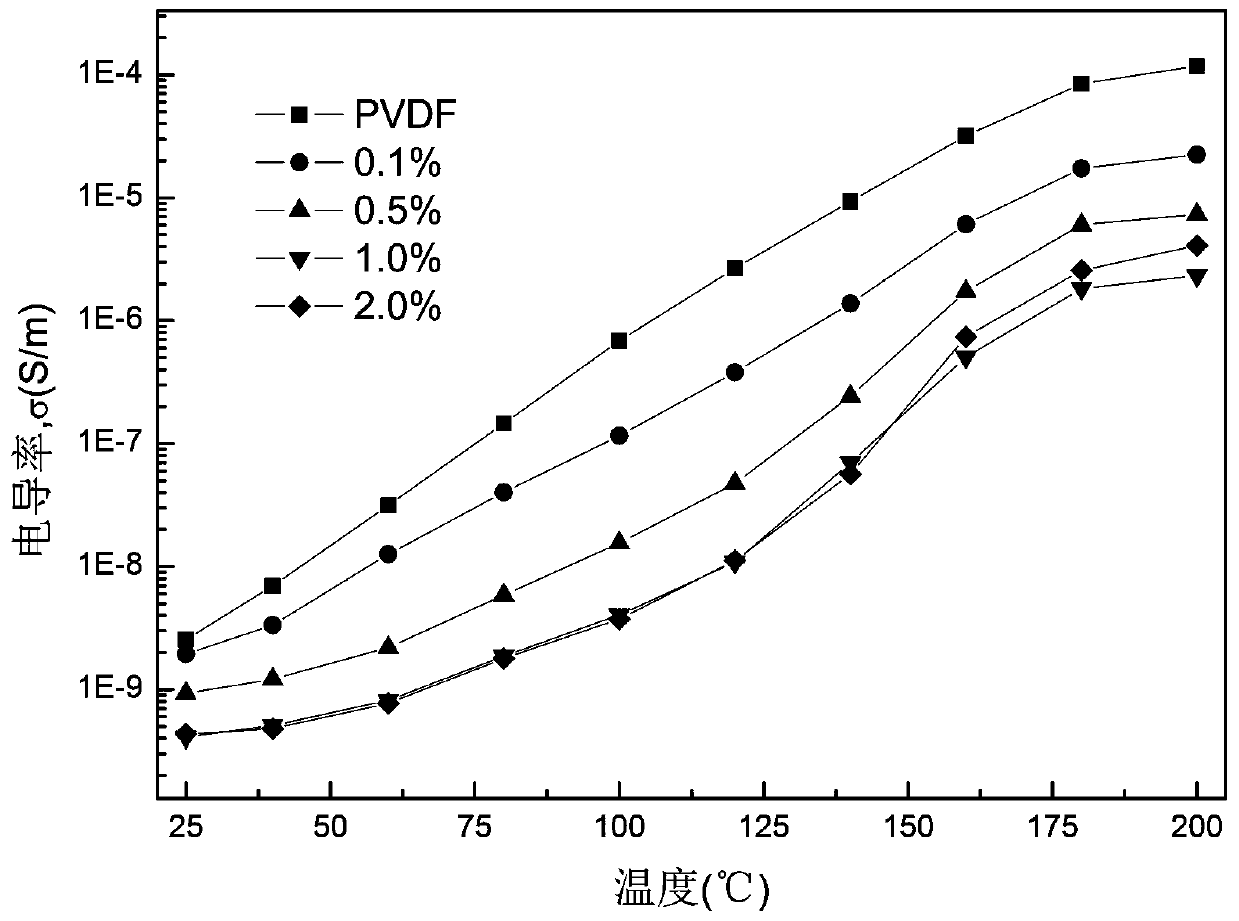

Image

Examples

Embodiment 1

[0029] (1) Dissolve 2.0g of pure P(VDF-HFP) in 18.0g of N,N-dimethylformamide (DMF) solvent, stir at 40°C for 60min, and ultrasonically disperse for 50min to form a uniform and stable solution A;

[0030] (2) Dissolve 0.002g of fluorinated graphene in 2.0g of DMF solvent, stir at 40°C for 60min, and ultrasonically disperse for 50min to form a stable suspension B;

[0031] (3) Mix the solutions A and B obtained in steps (1) and (2), stir at 40°C for 60 minutes, and ultrasonically disperse for 50 minutes to obtain a uniform and stable solution C;

[0032] (4) First, the solution A prepared in step (1) is poured on an ultra-flat petri dish by solution casting method, and then dried at 70° C. for 60 min to form a P(VDF-HFP) bottom layer; then step (3) Pouring the solution C prepared in the P(VDF-HFP) layer on the P(VDF-HFP) layer and continuing to dry for 60min to form the FGN / P(VDF-HFP) intermediate layer; pouring the solution A in step (1) on the intermediate layer and continui...

Embodiment 2

[0037] (1) Dissolve 2.0g of pure P(VDF-CTFE) in 16.0g of N,N-dimethylformamide (DMF) solvent, stir at 50°C for 50min, and ultrasonically disperse for 40min to form a uniform and stable solution A;

[0038] (2) 0.01 g of fluorinated graphene was dissolved in 4.0 g of DMF solvent, stirred at 50° C. for 50 min, and ultrasonically dispersed for 40 min to form a stable suspension B;

[0039] (3) Mix the solutions A and B obtained in steps (1) and (2), stir at 50°C for 50 minutes, and ultrasonically disperse for 40 minutes to obtain a uniform and stable solution C;

[0040] (4) First, the solution A prepared in step (1) is poured on an ultra-flat petri dish by solution casting method, and then dried at 80° C. for 50 min to form a P(VDF-CTFE) bottom layer; then step (3) The solution C prepared in is poured on the P(VDF-CTFE) layer and continued to dry for 50min to form the FGN / P(VDF-CTFE) intermediate layer; the solution A in step (1) was poured on the intermediate layer and continued...

Embodiment 3

[0045] (1) Dissolve 2.0g of pure P(VDF-TrFE) in 14.0g of N,N-dimethylformamide (DMF) solvent, stir at 60°C for 40min, and ultrasonically disperse for 30min to form a uniform and stable solution A;

[0046] (2) Dissolve 0.02 g of fluorinated graphene in 6.0 g of DMF solvent, stir at 60° C. for 40 min, and ultrasonically disperse for 30 min to form a stable suspension B;

[0047] (3) Mix the solutions A and B obtained in steps (1) and (2), stir at 60°C for 40 minutes, and ultrasonically disperse for 30 minutes to obtain a uniform and stable solution C;

[0048] (4) First, the solution A prepared in step (1) is poured on an ultra-flat petri dish by solution casting method, and then dried at 90° C. for 40 min to form a P(VDF-TrFE) bottom layer; then step (3) The solution C prepared in is poured on the P(VDF-TrFE) layer and continued to dry for 40min to form the FGN / P(VDF-TrFE) intermediate layer; the solution A in step (1) was poured on the intermediate layer and continued to dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com