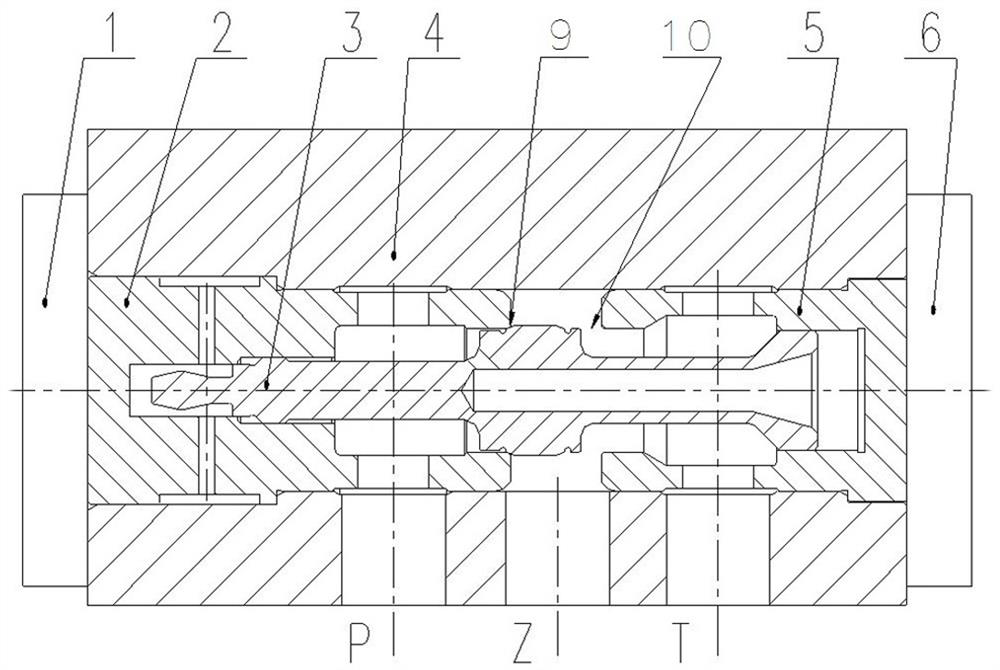

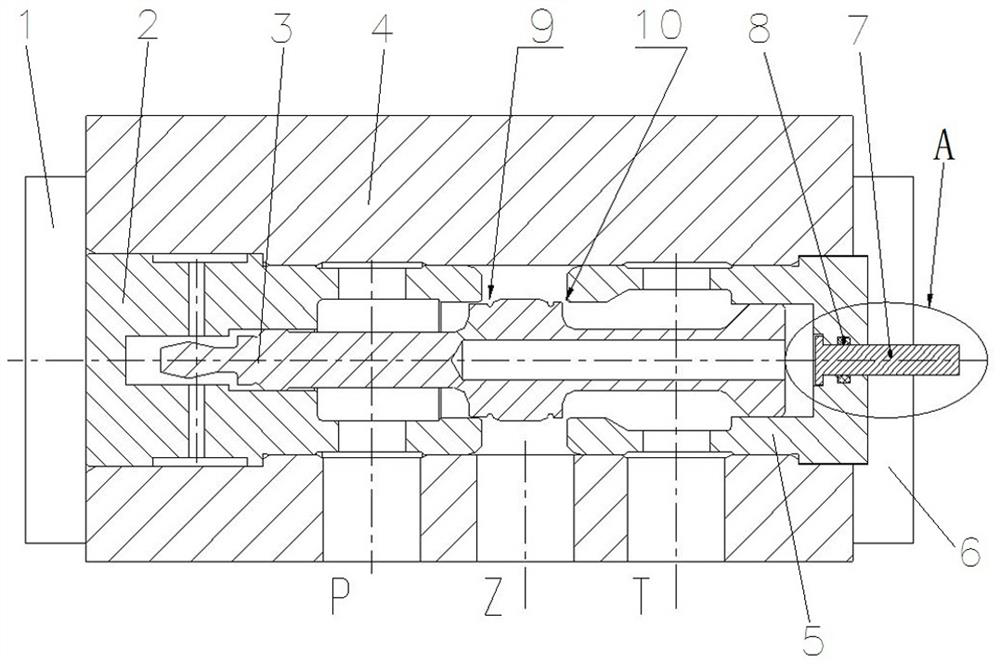

Hydraulic actuators, control valves and main valves of control valves

A technology for hydraulically operating and controlling valves, which is applied to engine components, fluid pressure actuators, multi-way valves, etc., and can solve problems such as manual operation of the spool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

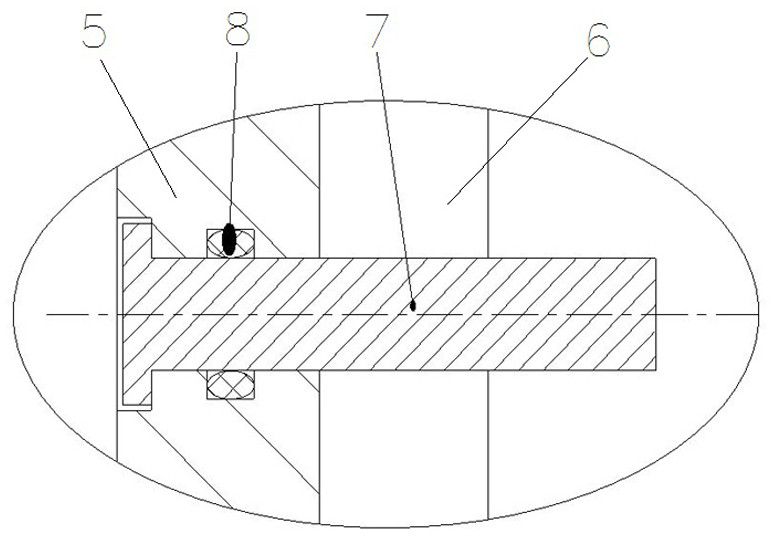

[0036] Embodiment 2 The second embodiment is different from the first embodiment in that the main valve of the control valve does not include the operating lever, the operating lever is additionally provided; the control valve is blocked when the valve is worked, such as a screw, and the main valve valve body The end of the operating lever is blocked; when the maintenance is required, the sealing member is removed and the operating lever is introduced into the operating lever perforation.

Embodiment 3

[0037] Example III, Embodiment 3 Examples An Example One is in that one end of the operating member is connected by a threaded structure and a main valve valve core; when the main valve spool is not in place, drive or pull the operating rod to drive Main valve spool action.

Embodiment 4

[0038] Example 4, Example 4 Example 4 Different Embodiment An Spring of the operating rod and the main valve body is provided to apply a reset force to the operating lever, after the manual operation is completed, the operating rod is in the spring force Automatically reset automatically.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com