On-load tap-changer pressure relief valve dismounting device and method capable of avoiding oil drainage

A technology of on-load tap and disassembly device, applied in the direction of hand-held tools, manufacturing tools, etc., can solve the problems of increasing the workload of on-site maintenance personnel, reducing work efficiency, waste of insulating oil, etc., achieving simple structure, improved work efficiency, Avoid a lot of wasteful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

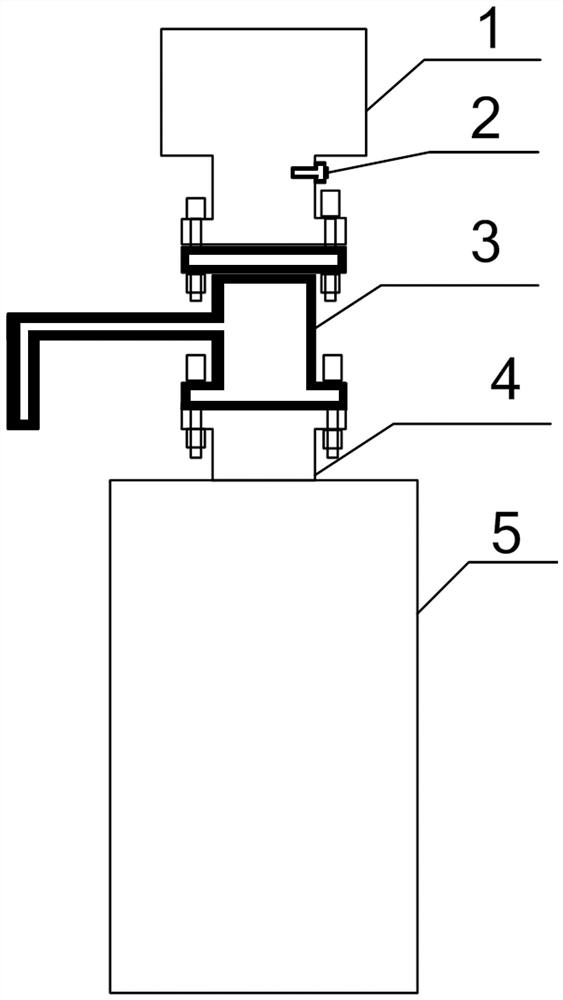

[0033] The present invention provides an embodiment, the present invention is an on-load tap-changer pressure relief valve removal device that avoids oil discharge, such as figure 1 as shown, figure 1 It is a schematic diagram of the composition and structure of the device in the present invention.

[0034] The invention is a dismantling device for a pressure release valve of an on-load tap changer that avoids oil discharge. The present invention mainly includes a pressure release valve 1 , a vent plug 2 , a valve 3 , an oil pipe 4 connected to an oil chamber upper cover of an on-load tap changer and an oil chamber 5 of an on-load tap changer. Wherein, the top of the on-load tap-changer oil chamber 5 is connected with the oil pipe 4 connected to the upper cover of the on-load tap-changer oil chamber, and the oil chamber 5 of the on-load tap-changer and the oil pipe 4 connected to the upper cover of the on-load tap-changer oil chamber are an integral structure .

[0035] The...

Embodiment 2

[0038] The present invention provides yet another embodiment. The present invention is a method for disassembling the pressure relief valve of an on-load tap changer that avoids oil discharge, comprising the following steps:

[0039] Step 1: When the service life of the pressure relief valve reaches the maintenance period, it is necessary to close the vent plug and valve, and disassemble the pressure relief valve to verify its performance;

[0040] Step 2: Unscrew the bolts connecting the pressure relief valve and the valve, and remove the pressure relief valve;

[0041] This can effectively avoid oil discharge from the oil chamber of the on-load tap-changer and the oil conservator, and at the same time avoid a large amount of waste of insulating oil and pollution of the oil chamber of the on-load tap-changer and its accessories exposed to the air;

[0042] Step 3: Install the qualified pressure relief valve and tighten the connecting bolts between the pressure relief valve an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com