Transformer accessory converting all-in-one machine and using method thereof

A technology of a transformer and an all-in-one machine, which is applied in the field of replacing the all-in-one machine with transformer accessories, can solve the problems of time-consuming, large manpower and material resources, and achieve the effects of simple use method, saving manpower and material resources, and avoiding oil leakage and oil discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

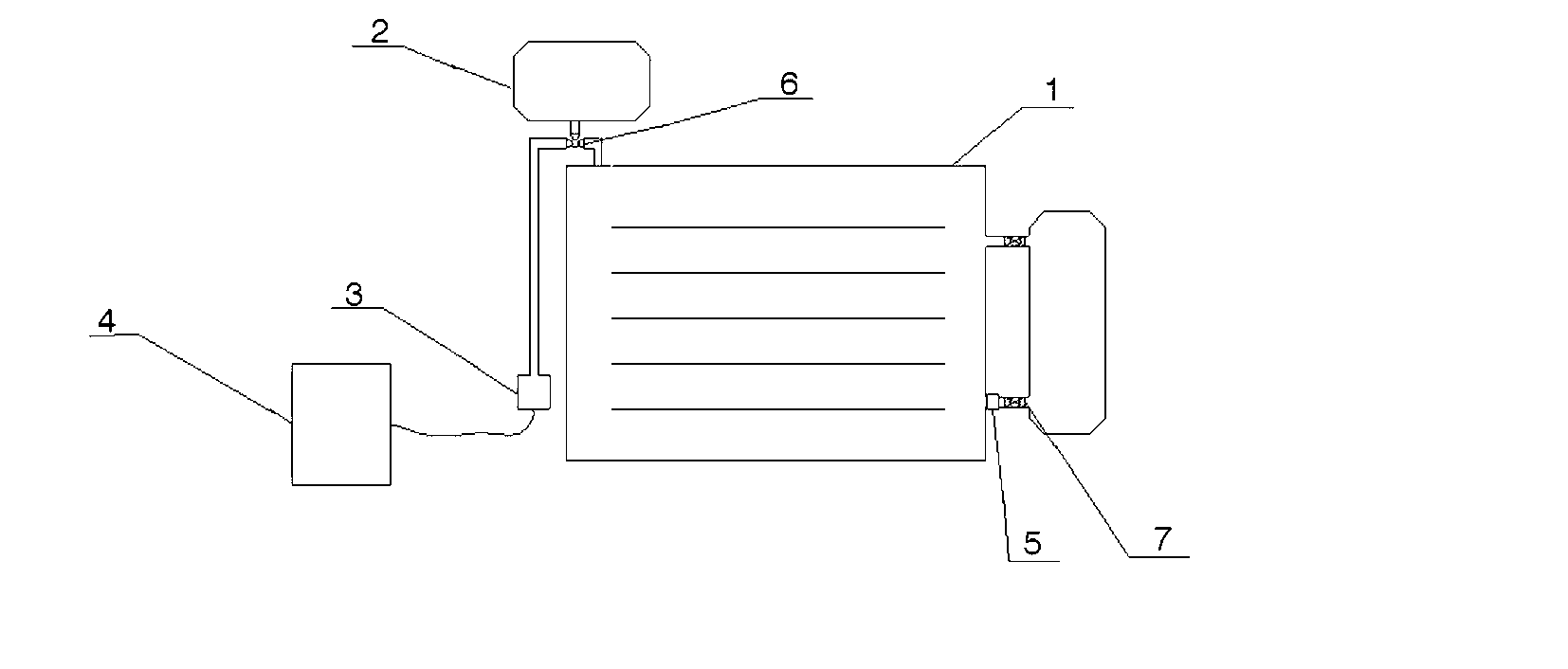

[0029] Example 1 Replacement of the butterfly valve at the lower connecting pipe between the main transformer body and the cooler

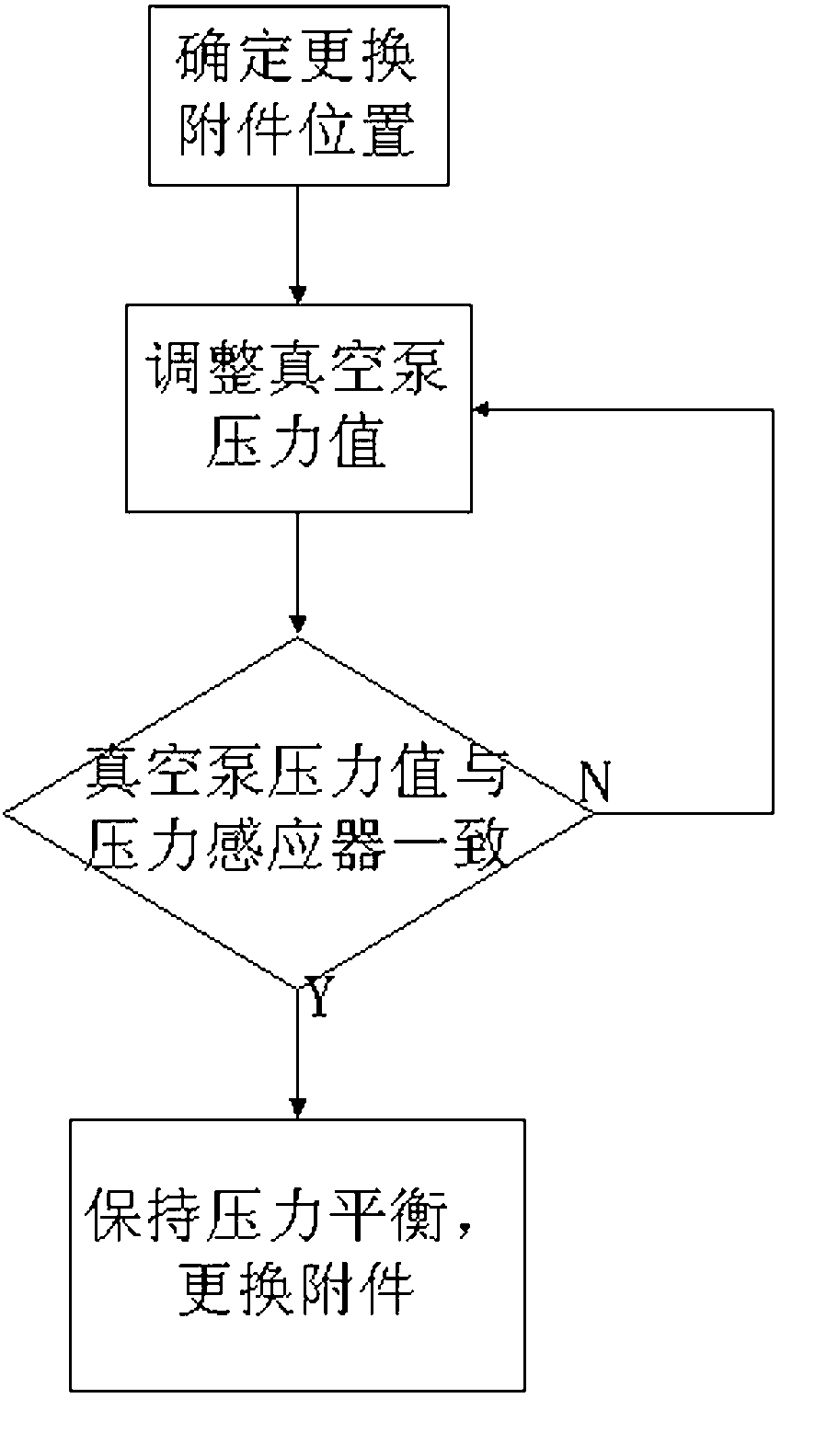

[0030] First, measure the pressure value of the oil level here through the pressure sensor installed in the horizontal position of the butterfly valve. By measuring the depth of the oil level here is h=4 meters, and through the pressure calculation formula Calculate and verify the correctness of the pressure value measured by the pressure sensor. Then start the vacuum pump to evacuate the body. The pressure value of the vacuum pump is F=PS, where S is the cross-sectional area of the connecting pipe (the connecting pipe of the respirator, through which the air pump is vacuumed), and P is the value measured by the pressure sensor. When the pressure gauge of the vacuum pump is stable, the pressure at the attachment to be replaced is balanced inside and outside, and the attachment can be replaced without draining oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com