Construction method for cable-stayed bridge dismantling

A construction method and technology for cable-stayed bridges, applied in cable-stayed bridges, bridges, bridge forms, etc., can solve the problems of reduced axial compressive stress of main girder, unknown cable force of old hangers, and reduced bending resistance, etc. Realize the effects of smooth lowering, convenient anchoring, strong stability and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention is described in detail below in conjunction with accompanying drawing:

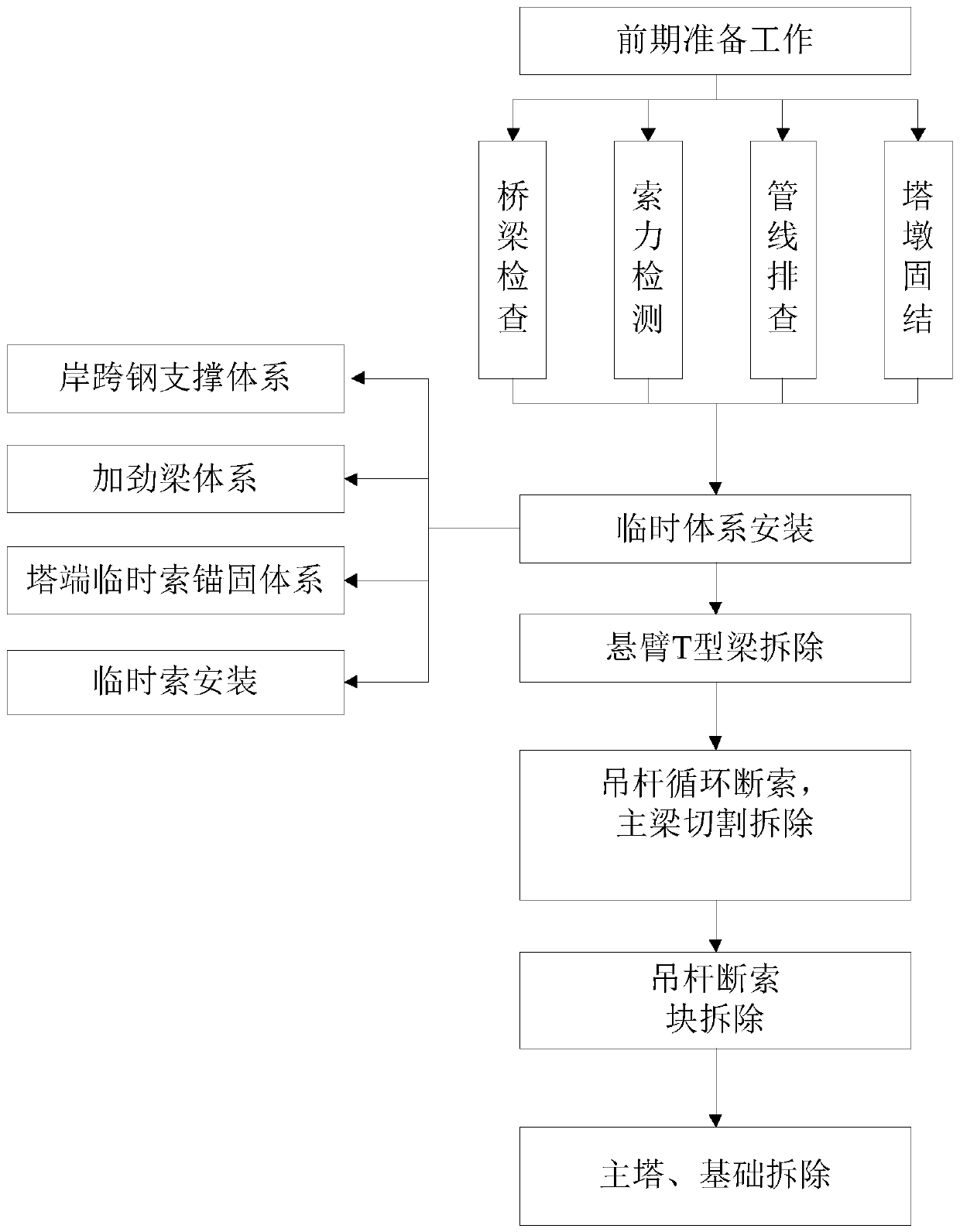

[0059] Such as figure 1 Shown, a kind of cable-stayed bridge demolition construction method mainly comprises the following several steps that carry out successively:

[0060] 1. Preparatory work.

[0061] 1.1 Check the condition of the original bridge.

[0062] Since the bridge has been in operation for a long time and the current bearing status is unknown, in order to ensure the safety of the bridge during the demolition process, a comprehensive inspection of the bridge must be carried out before the detailed implementation plan is compiled. The main detection contents are as follows:

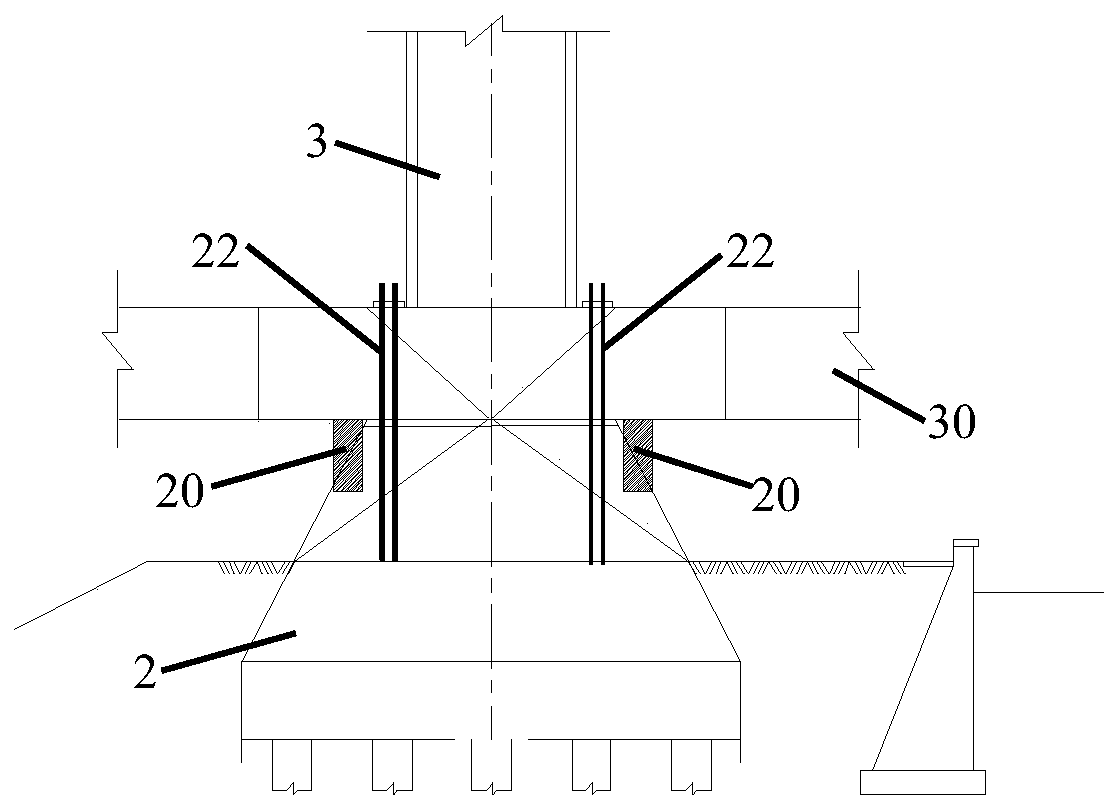

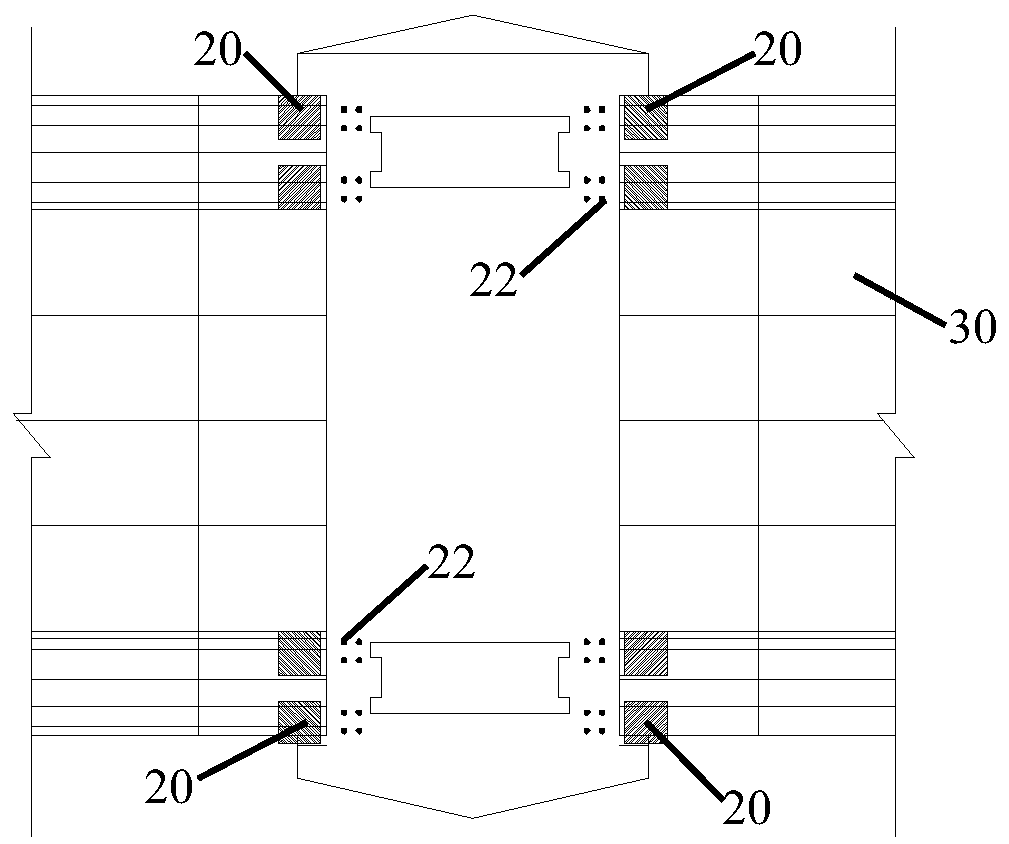

[0063] (1) Concrete strength of bridge beam body 1, pier body 2 and main tower 3;

[0064] (2) The actual cable force detection of the stay cable 4, and the corrosion situation of the anchoring end and the tension end at both ends of the stay cable 4 are detected simultaneously;

[0065] (3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com