Method for preparing furfural and co-producing fiberboard by extracting xylose through reed steam explosion

A fiberboard and reed technology, applied in the field of plant extraction, can solve the problems of uneven distribution of laccase enzyme activity, long growth cycle of microorganisms, low production efficiency of pressing plate, etc., and achieve the effects of saving steam, good comprehensive utilization and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

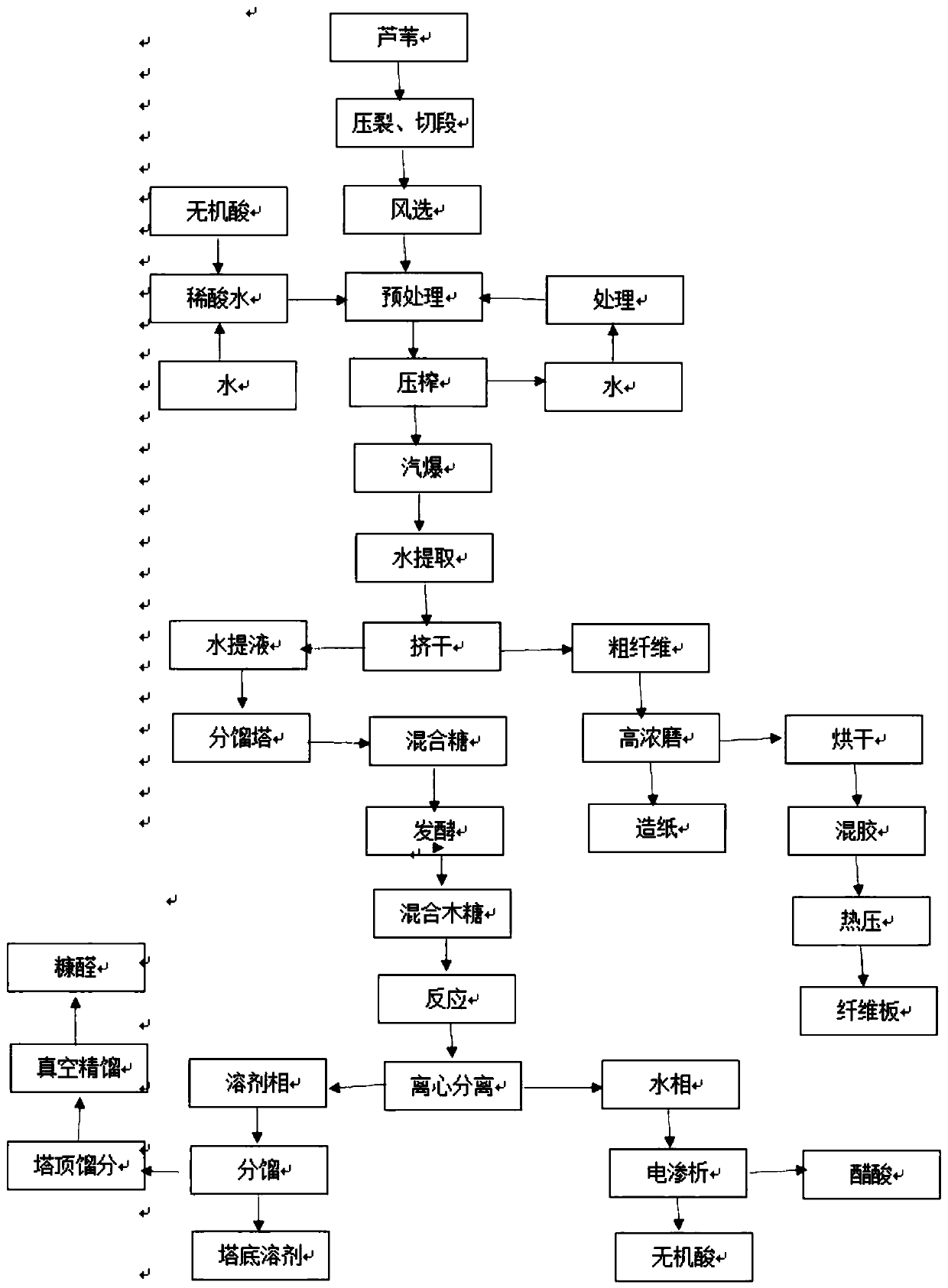

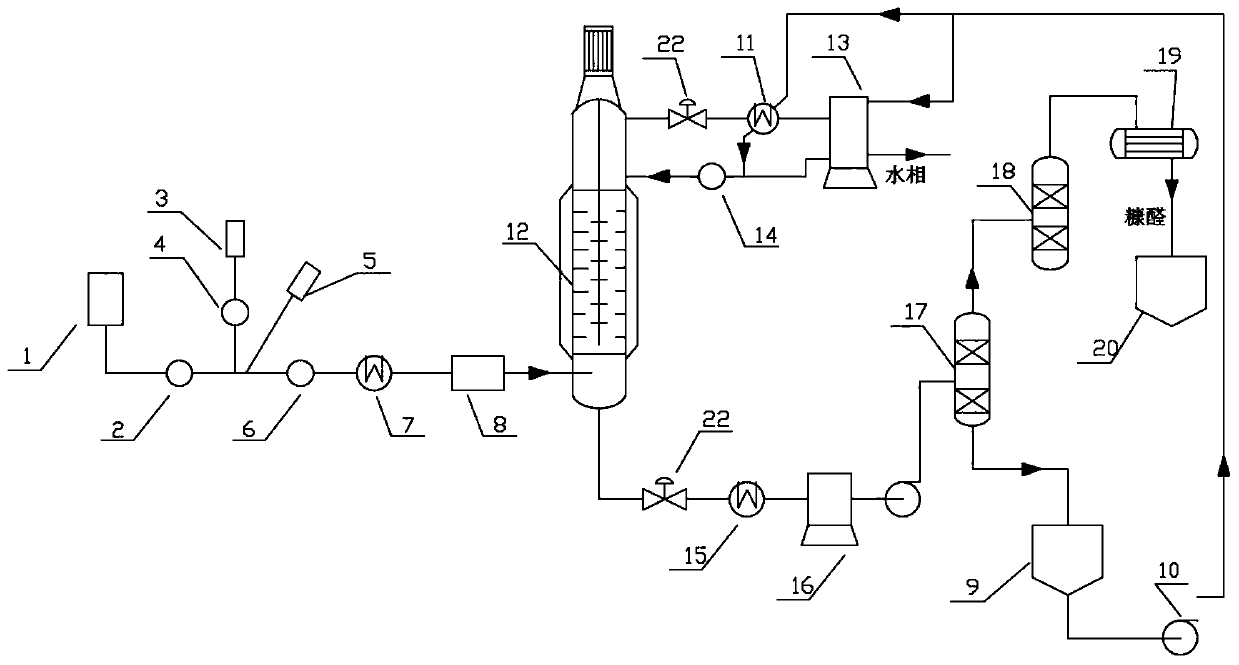

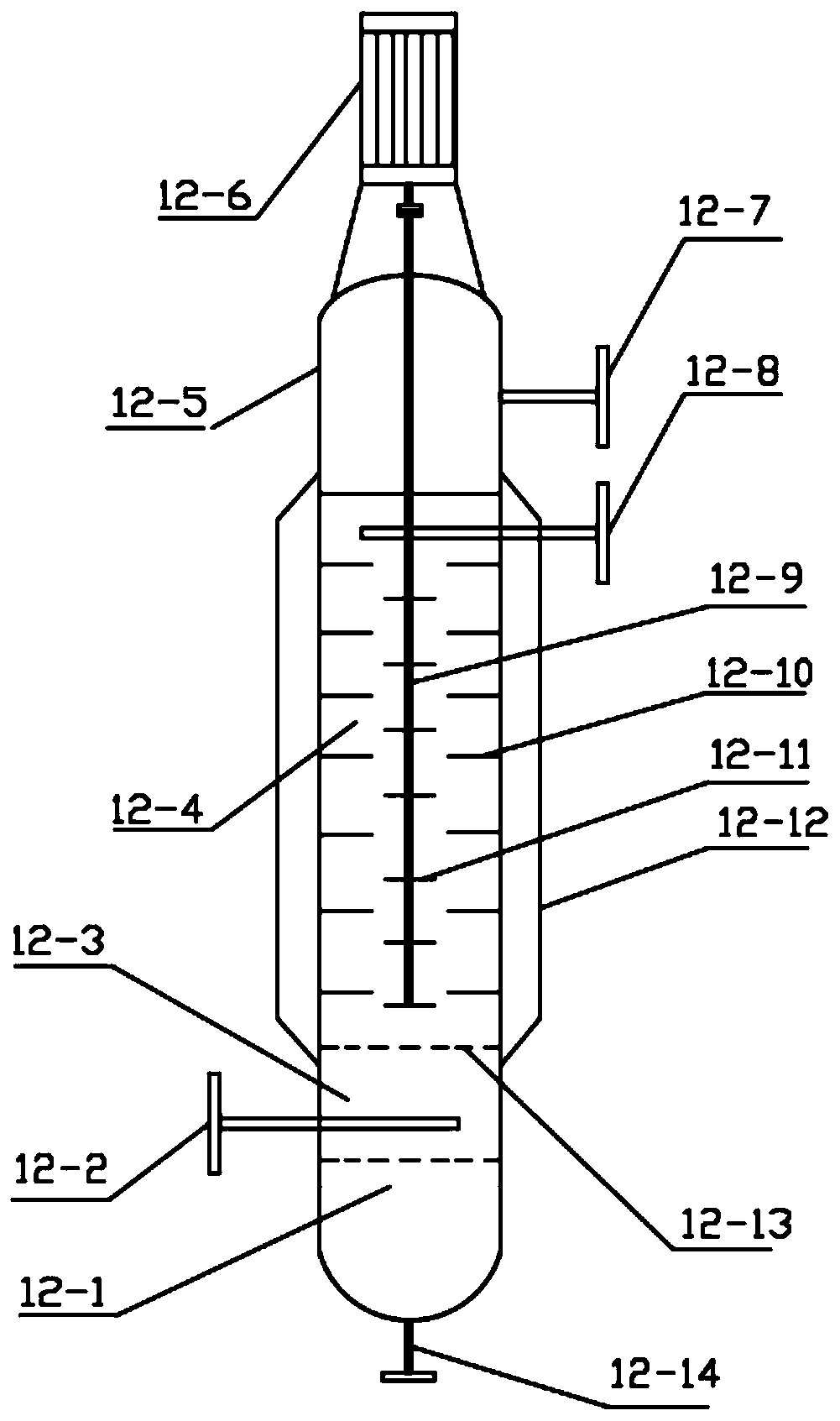

[0076] A method for extracting xylose by reed steam explosion to prepare furfural, comprising the following steps:

[0077] 1) Raw reeds (water content 40wt% or fresh reeds) are fractured and cut into sections with a length of 20-40mm;

[0078] 2) Conveying by wind, while separating impurities such as reed leaves, reed flowers and flute membranes, it is the raw material for steam explosion;

[0079] 3) Add dilute sulfuric acid with a concentration of 0.3wt% to the above-mentioned raw materials, the solid-to-liquid ratio is 1:0.8, and mix evenly with a ribbon mixer; after mixing for 30 minutes, press to make the water content of the treated reed 45wt%. Send it into the steam blaster, under the steam pressure of 1.6Mpa and the temperature of 180°C, hold it for 120 seconds, and explode instantly.

[0080] After the steam explosion, the material is washed with 10 times the mass of hot water at 70°C in a continuous pulp washer, and then pressed and dehydrated to obtain a mixture o...

Embodiment 2

[0091] A method for extracting xylose by reed steam explosion to prepare furfural, comprising the following steps:

[0092] 1) Raw reeds are crushed and cut into sections, with a length of 20-40mm;

[0093] 2) Conveying by wind, while separating impurities such as reed leaves, reed flowers and flute membranes, it is the raw material for steam explosion.

[0094] 3) Add dilute sulfuric acid with a concentration of 0.3% (wt / wt) to the above-mentioned steam explosion raw materials, the solid-to-liquid ratio is 1:0.8, and mix evenly with a mixer; the mixer can be a ribbon type or a drum type, Maintain for 30 minutes and press to make the water content of the treated reed 45wt%. Send it into a steam blaster at a steam pressure of 1.6Mpa and a temperature of 180°C for 120 seconds to explode instantly.

[0095] After the steam explosion, the material is washed with 10 times of 70°C hot water in a continuous pulp washer, and then pressed and dehydrated to obtain a mixture of solid c...

Embodiment 3

[0106] Reeds are not subjected to steam explosion treatment, and fiberboards are produced by conventional methods.

[0107] The above three examples were made of MDF under the same conditions and tested according to the GB / T11718-009 standard. The comparison results are as follows:

[0108]

[0109]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com