A device and method for preparing aromatics by coal staged hydropyrolysis

A hydrogenation device and hydrogen heating technology, applied in the field of coal chemical industry, can solve the problems of poor carbon atom economy, low yield of aromatic hydrocarbon-containing oil, complex process flow, etc., and achieve high utilization rate of raw materials and energy efficiency, simple structure and composition of the device, The effect of short method flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

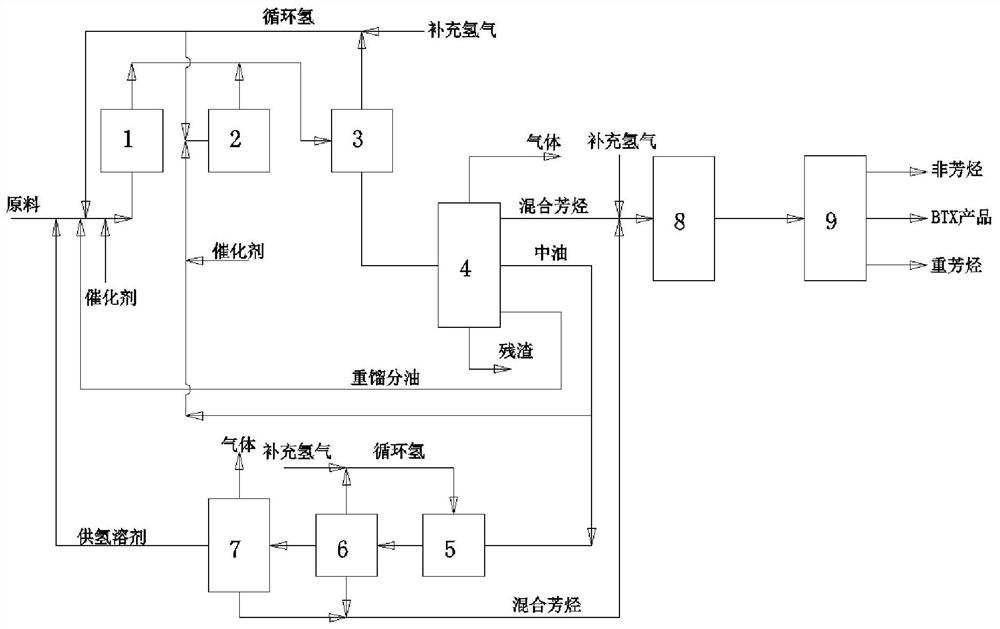

[0079] This embodiment provides a device for preparing aromatics by coal staged hydropyrolysis, the structural connection schematic diagram of the device is as follows figure 1 As shown, it includes a primary hydropyrolysis reactor 1, a secondary hydropyrolysis reactor 2, a hydropyrolysis product separation unit 3, a hydropyrolysis product fractionation unit 4, and a mixed aromatics hydrogenation unit 8;

[0080] The outlet of the primary hydropyrolysis reactor 1 and the outlet of the secondary hydropyrolysis reactor 2 are connected to the inlet of the hydropyrolysis product separation unit 3, and the hydropyrolysis product separation unit 3 The oil and gas outlet is connected to the inlet of the hydrogenation pyrolysis product fractionation unit 4, and the mixed aromatics outlet of the hydrogenation pyrolysis product fractionation unit 4 is connected to the inlet of the mixed aromatics hydrogenation device 8, and the hydrogenation pyrolysis product fractionation unit 4 The me...

Embodiment 2

[0087] This embodiment provides a device for preparing aromatics by coal staged hydropyrolysis. The structure of the device refers to the structure in Example 1, the only difference is that the first-stage hydropyrolysis reactor 1 includes 3 sets A series of forced circulation suspended bed reactors, the secondary hydropyrolysis reactor 2 includes a forced circulation suspended bed reactor; the solvent oil hydrogenation reactor 5 includes a fixed bed reactor and a mobile The bed reactors are connected in series.

Embodiment 3

[0089] This embodiment provides a device for preparing aromatics by coal staged hydropyrolysis. The structure of the device refers to the structure in Example 1, the only difference is that the first-stage hydropyrolysis reactor 1 includes two One-pass suspended bed reactors connected in series, the secondary hydropyrolysis reactor 2 includes 2 one-pass suspended bed reactors; the device does not include solvent oil hydrogenation reactor 5, solvent oil Hydrogenation product separation unit 6 and solvent oil hydrogenation product fractionation unit 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com