Microcapsule containing sialic acid and carotenoid, and preparation method and application of microcapsule

A technology of carotene and microcapsules, which is applied in the field of food processing, can solve problems such as easy oxidation, unstable sialic acid, and large loss, and achieve the effects of overcoming instability, good shelf life stability, and poor mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

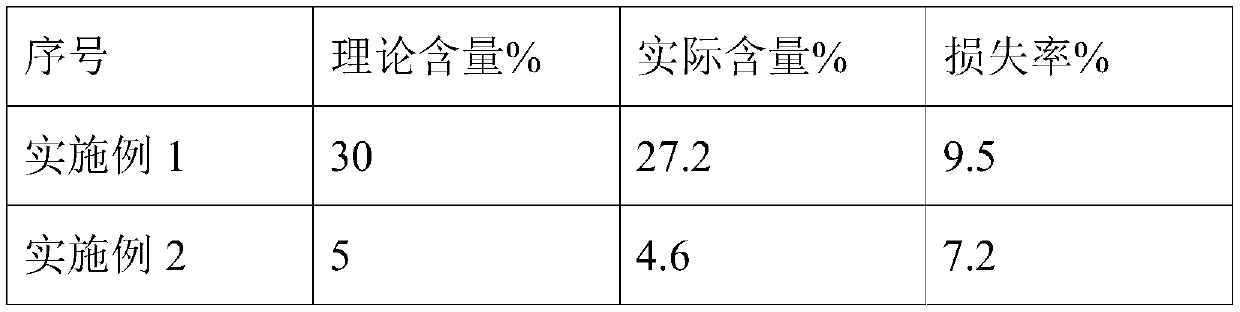

Examples

Embodiment 1

[0071] This embodiment provides a microcapsule containing sialic acid and β-carotene, the microcapsules include the following preparation raw materials in mass percentage: 8% β-carotene, 25% rapeseed oil, 2% ascorbyl palmitate %, sialic acid 30%, sodium caseinate 10%, cyclodextrin 9%, sodium ascorbate 2%, solid corn syrup 14%.

[0072] Its preparation method is:

[0073] (1) Mix β-carotene, rapeseed oil and ascorbyl palmitate, shear at a rate of 12000r / min for 12min under nitrogen protection at 25°C, disperse evenly, and melt the above mixture instantaneously within 5s at 150°C , to obtain the oil suspension;

[0074] (2) Add water to sialic acid, sodium ascorbate, cyclodextrin, solid corn syrup, and sodium caseinate until the solid content is 60%, and shear at a rate of 10,000 r / min for 20 minutes at 40°C to obtain the wall material fluid;

[0075] (3) Mix the oil suspension prepared in steps (1) and (2) with the wall material solution, shear at a rate of 15000r / min for 10...

Embodiment 2

[0078] This example provides a microcapsule containing sialic acid and β-carotene, the microcapsules include the following preparation raw materials in mass percentage: 1% β-carotene, 17% rapeseed oil, 1% ascorbyl palmitate %, sialic acid 5%, sodium starch octenyl succinate 20%, maltodextrin 29%, sodium ascorbate 1%, solid corn syrup 26%.

[0079] Its preparation method is:

[0080] (1) Mix β-carotene, rapeseed oil and ascorbyl palmitate, shear at a rate of 8000r / min for 20min under nitrogen protection at 15°C, and disperse evenly. Melt to obtain the oil suspension;

[0081] (2) Add water to sialic acid, sodium ascorbate, maltodextrin, solid corn syrup, and sodium starch octenyl succinate until the solid content is 40%, and shear at a rate of 8000r / min for 20min at 35°C, obtaining the wall material liquid;

[0082] (3) Mix the oil suspension prepared in steps (1) and (2) with the wall material solution, shear at a rate of 10000r / min for 4min at 35°C, and then homogenize 3 t...

Embodiment 3

[0085]This embodiment provides a microcapsule containing sialic acid and β-carotene, the microcapsules include the following preparation raw materials in mass percentage: 2% β-carotene, 15% sunflower oil, monoglyceride stearic acid Esters 1%, Vitamin E 2%, Sialic Acid 20%, Starch Sodium Octenylsuccinate 20%, Maltodextrin 20%, Sodium Ascorbate 2%, Corn Syrup Solid 18%.

[0086] Its preparation method is:

[0087] (1) Mix β-carotene, sunflower oil, monoglyceride stearate and vitamin E, shear at a rate of 12000r / min for 15min under nitrogen protection at 35°C, disperse evenly, and put the above mixture at 170°C Melt down for 5s to obtain the oil suspension;

[0088] (2) Add water to sialic acid, sodium ascorbate, maltodextrin, solid corn syrup, and sodium starch octenyl succinate until the solid content is 50%, and shear at a rate of 18,000 r / min for 15 minutes at 50°C. obtaining the wall material liquid;

[0089] (3) Mix the oil suspension prepared in steps (1) and (2) with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com