Biosensor for detecting glutathione and fabrication method of biosensor

A biosensor, glutathione technology, applied in the field of biosensors, can solve the problems of complex procedures, difficult to generalize, time-consuming and poor sensitivity, and achieve the effects of low process cost, high sensitivity and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The preparation method of described chemiluminescence biosensor comprises the following steps:

[0056] The construction steps of composite probe P are as follows:

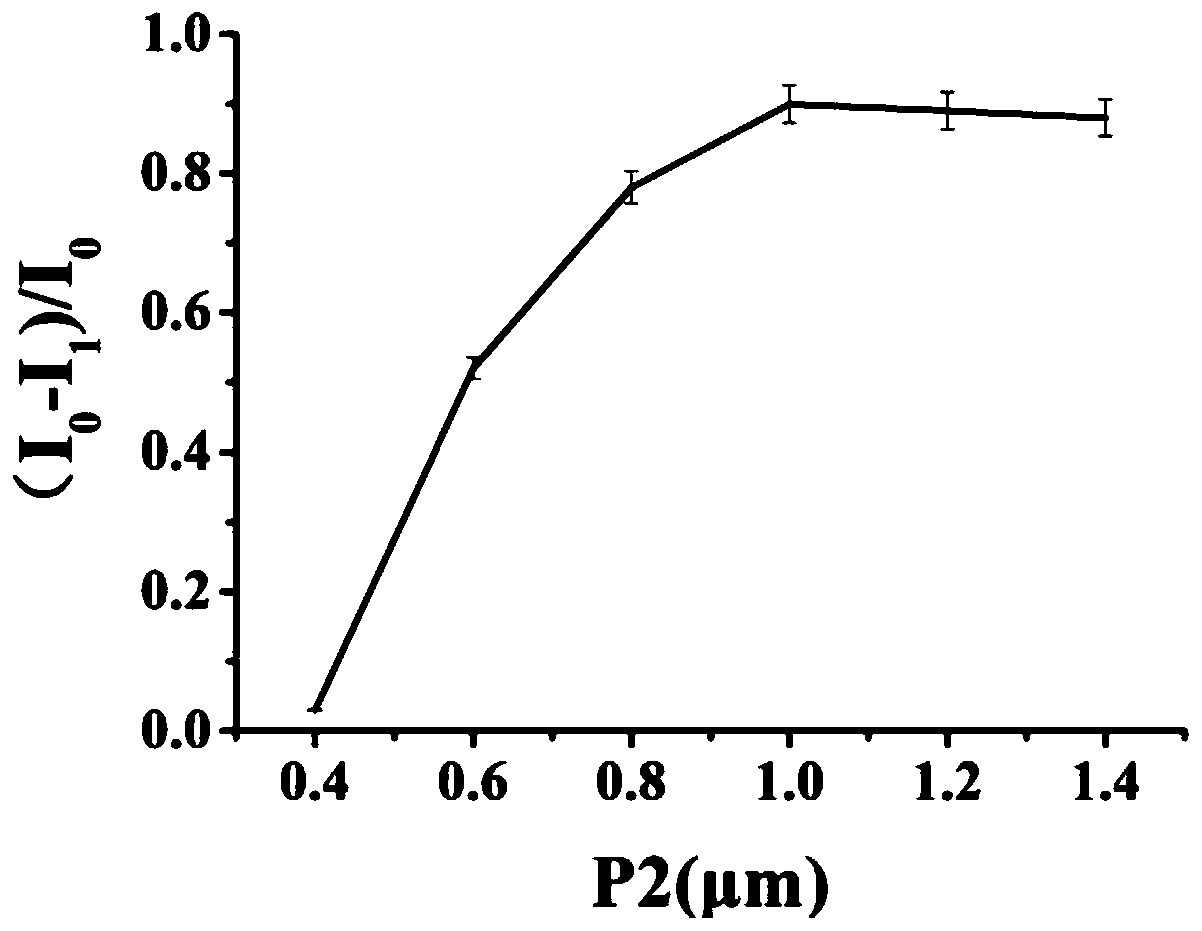

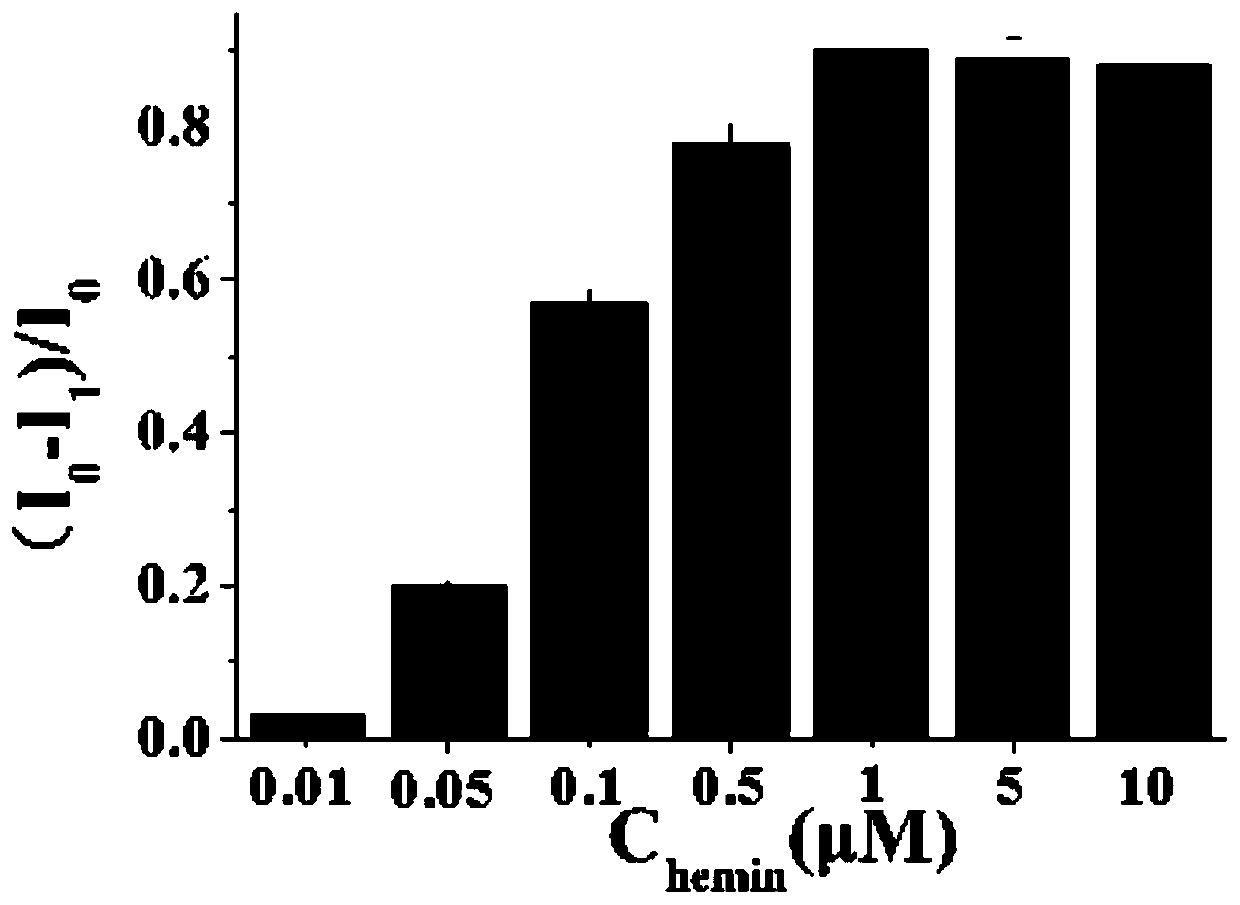

[0057]Add 18 μL of sterilized water, 3 μL of 10×PBS, 3 μL of 100 μM P0 probe, 3 μL of 100 μM P1 probe and 3 μL of 100 μM P2 probe into the pre-prepared sterile EP tube , shake for 30s, incubate at 95°C for 5min, slowly cool down to room temperature and hybridize as a probe, and store at -20°C for later use.

[0058] The operation steps of composite probe P modified to the surface of gold nanoparticles are as follows:

[0059] a. Take 1 mL nano-gold solution in a centrifuge tube, centrifuge for 15 min, and centrifuge the two tubes at the same time for later use. Centrifuge until the supernatant is colorless and transparent, remove the supernatant, and add 300 μL of sterile water to concentrate the nano-gold solution to 1 nM. Transfer to a 1 mL glass bottle and seal with tinfoil. After standing at room te...

Embodiment 2

[0069] The preparation method of described chemiluminescence biosensor comprises the following steps:

[0070] The construction steps of composite probe P are as follows:

[0071] Add 18 μL of sterilized water, 3 μL of 10×PBS, 3 μL of 100 μM P0 probe, 3 μL of 100 μM P1 probe and 3 μL of 100 μM P2 probe into the pre-prepared sterile EP tube , shake for 30s, incubate at 95°C for 5min, slowly cool down to room temperature and hybridize as a probe, and store at -20°C for later use.

[0072] The operation steps of composite probe P modified to the surface of gold nanoparticles are as follows:

[0073] a. Take 1 mL nano-gold solution in a centrifuge tube, centrifuge for 15 min, and centrifuge the two tubes at the same time for later use. Centrifuge until the supernatant is colorless and transparent, remove the supernatant, and add 300 μL of sterile water to concentrate the nano-gold solution to 1 nM. Transfer to a 1 mL glass bottle and seal with tinfoil. After standing at room t...

Embodiment 3

[0083] The preparation method of described chemiluminescence biosensor comprises the following steps:

[0084] The construction steps of composite probe P are as follows:

[0085] Add 18 μL of sterilized water, 3 μL of 10×PBS, 3 μL of 100 μM P0 probe, 3 μL of 100 μM P1 probe and 3 μL of 100 μM P2 probe into the pre-prepared sterile EP tube , shake for 30s, incubate at 95°C for 5min, slowly cool down to room temperature and hybridize as a probe, and store at -20°C for later use.

[0086] The operation steps of composite probe P modified to the surface of gold nanoparticles are as follows:

[0087] a. Take 1 mL nano-gold solution in a centrifuge tube, centrifuge for 15 min, and centrifuge the two tubes at the same time for later use. Centrifuge until the supernatant is colorless and transparent, remove the supernatant, and add 300 μL of sterile water to concentrate the nano-gold solution to 1 nM. Transfer to a 1 mL glass bottle and seal with tinfoil. After standing at room t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com