Energy consuming type bolt type connecting method used for concrete precast column and foundation connection

A connection method and prefabricated column technology, which is applied in the direction of basic structure engineering, building types, protected buildings/shelters, etc., can solve the problems of unguaranteed construction quality, complicated technological process, long construction period, etc., and achieve construction efficiency High quality, simple process flow and guaranteed construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

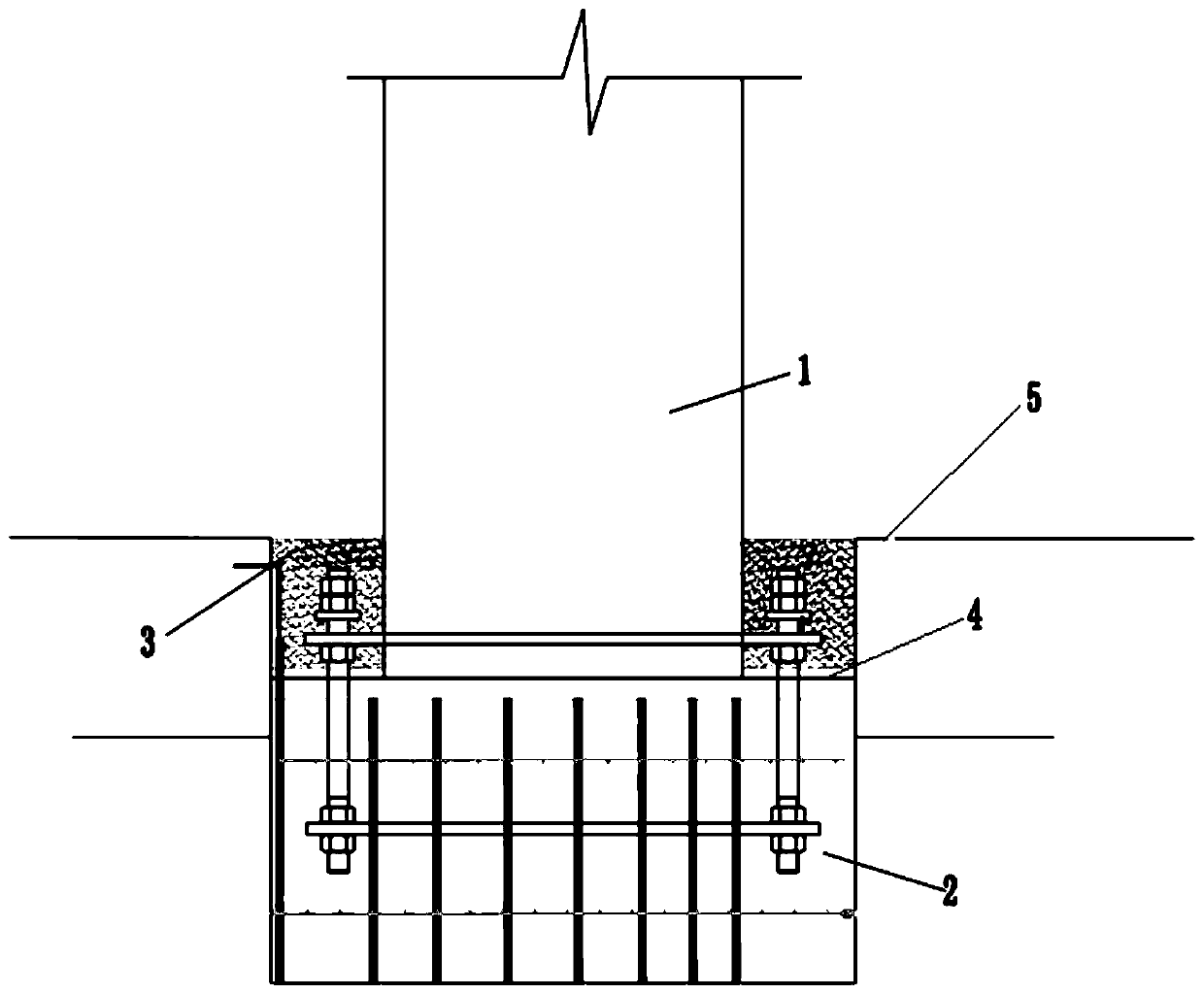

[0053] Example: Combine Figure 1-8 As shown, this embodiment includes an upper prefabricated part 1, a lower embedded part 2 located in the foundation foundation and a post-cast concrete 3. After the lower embedded part 2 is installed, concrete is poured, and the surface after pouring is the foundation surface 4 , which forms a cup foundation with the top surface of the foundation foundation; then the upper prefabricated part 1 and the lower embedded part 2 are connected, and the post-cast concrete 3 is finally poured with fine stone concrete of a higher strength level to the foundation foundation Concrete structure with flush top.

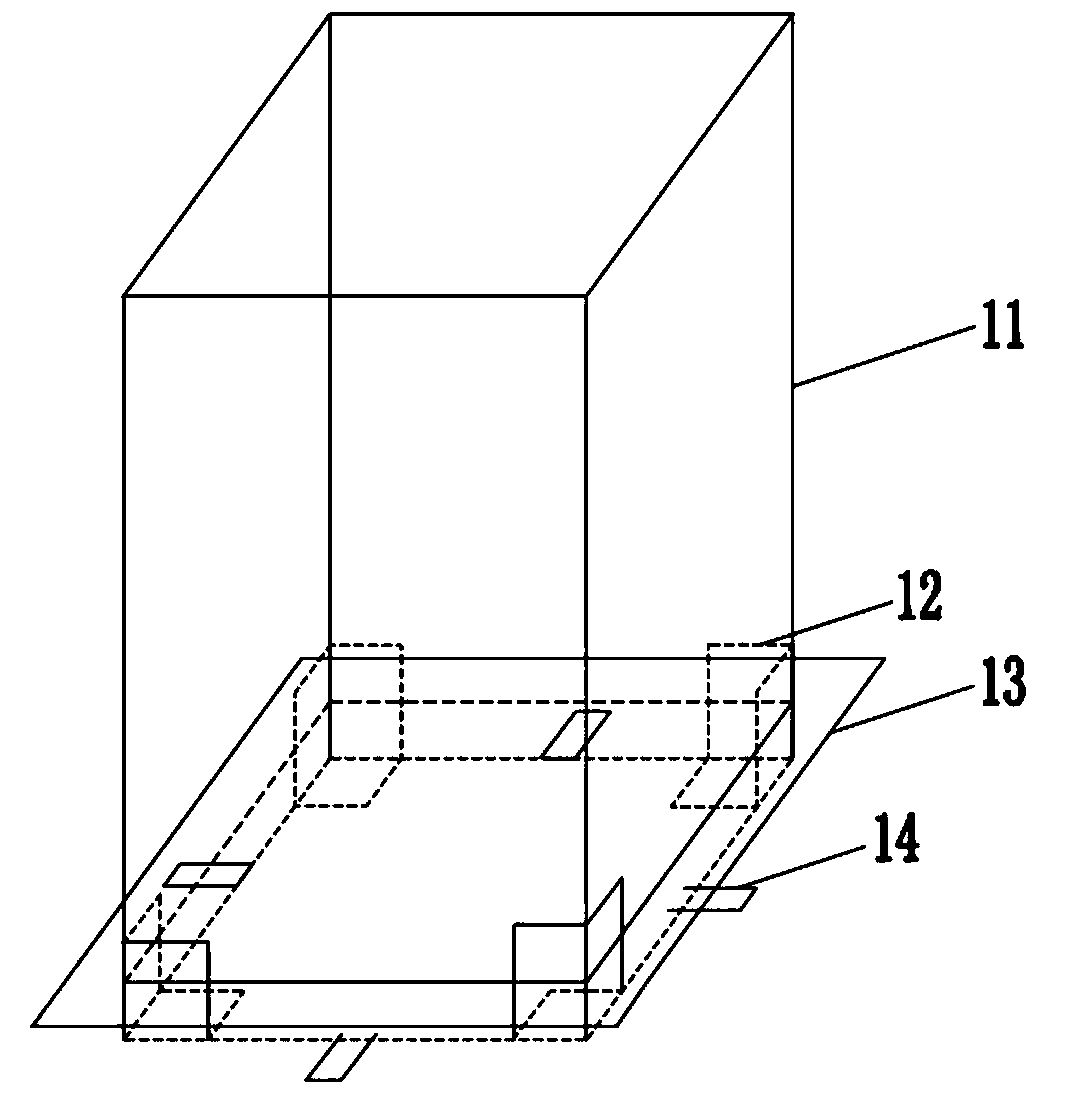

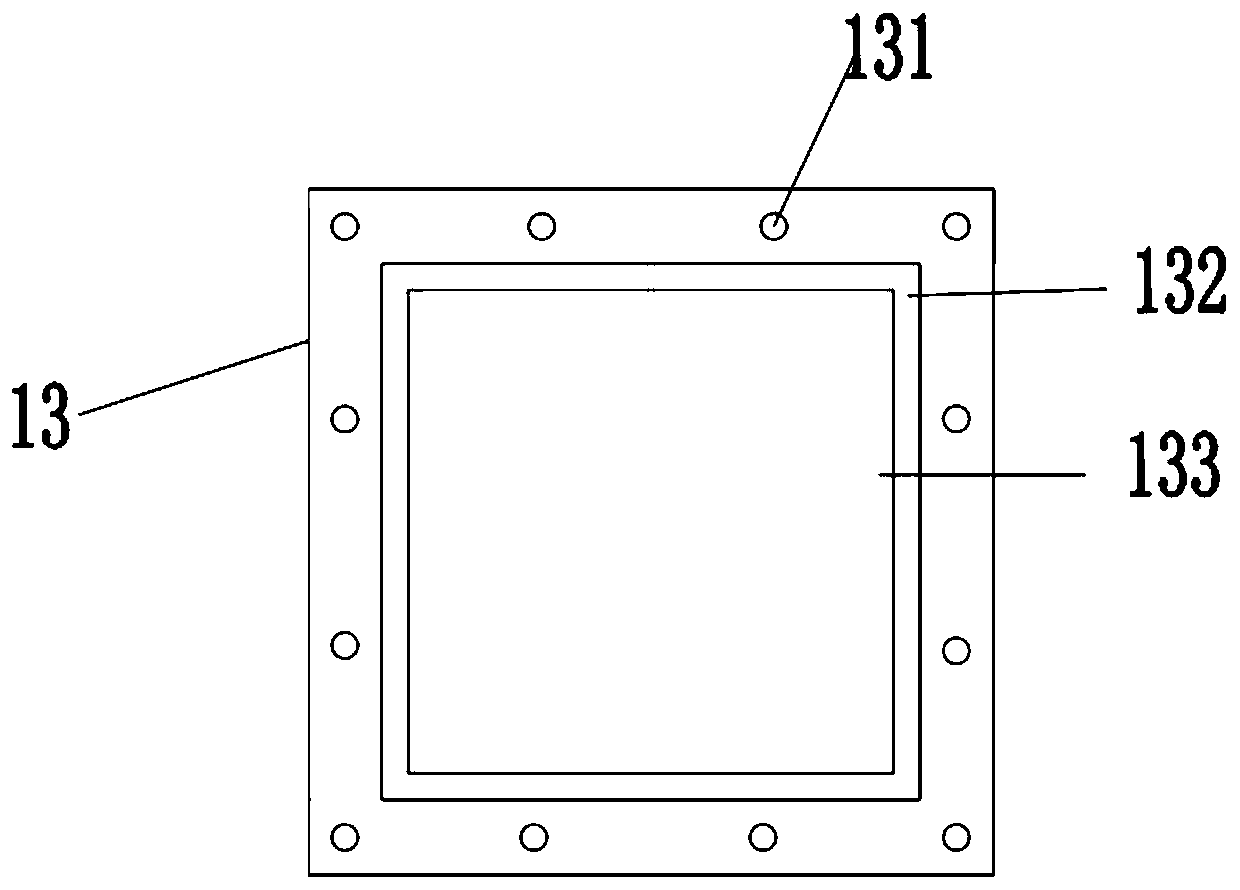

[0054] The upper prefabricated part 1 includes a prefabricated column 11 and an upper positioning plate 13. The prefabricated column 11 is a reinforced concrete cuboid structure, and its bottom four corners are respectively fixed with corner protectors 12. The corner protectors 12 have a thickness of 3mm, a width of 50mm, and a height of 30mm. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com