Preparation method of wear-resistant super-amphiphobic coating based on titanium dioxide/silica composite nanoparticles

A technology of composite nanoparticles and titanium dioxide, which is applied in coatings and other directions, can solve the problems of complicated preparation steps, poor weather resistance, and poor wear resistance of superamphiphobic materials, and achieve excellent mechanical and chemical stability, low cost, and raw materials. Easy to get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

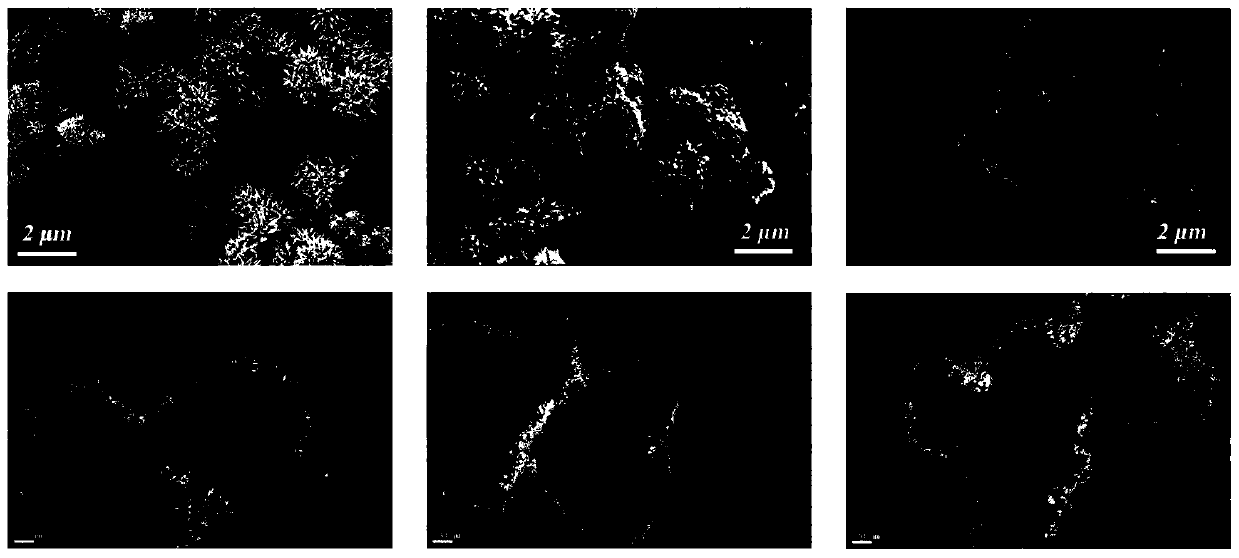

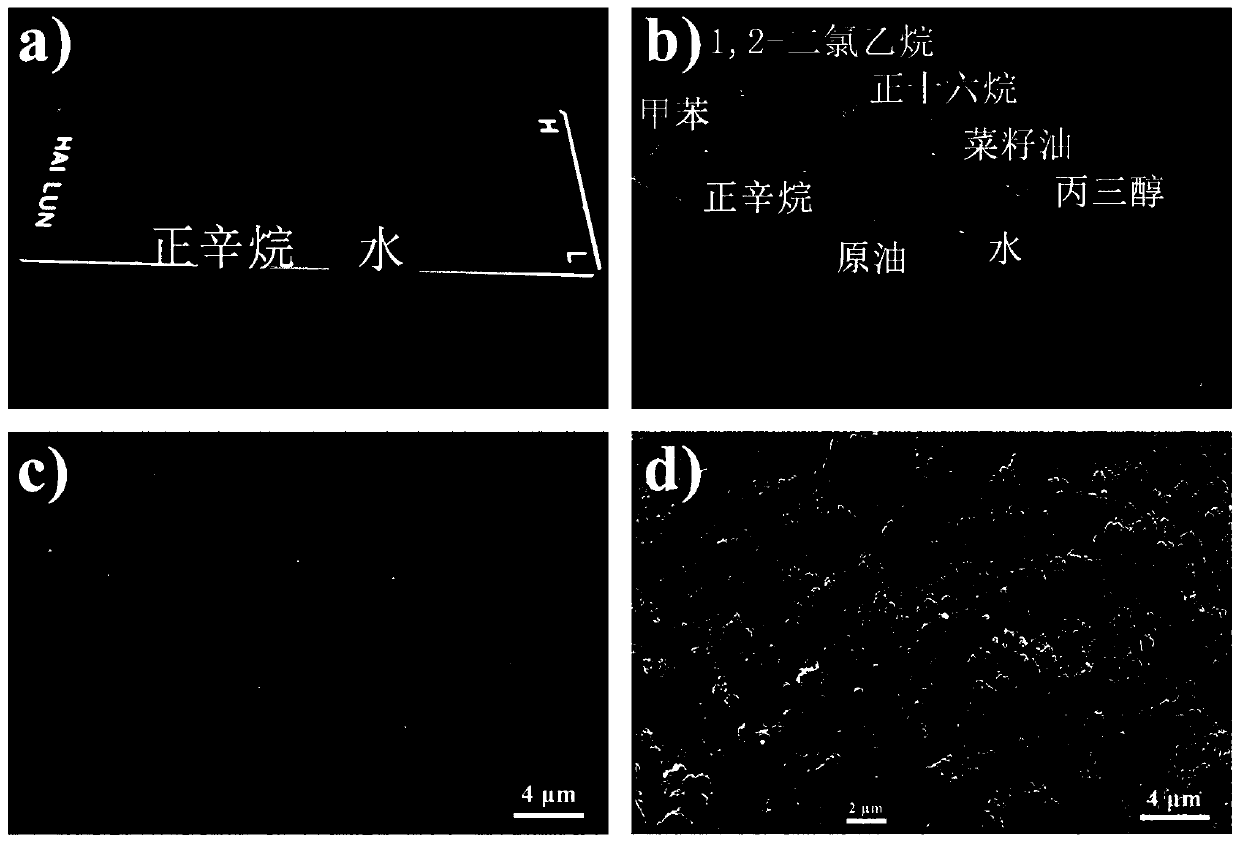

[0022] 1. Preparation of flower-like titanium dioxide particles: layered flower-like titanium dioxide nanoparticles were synthesized by a typical template-free solvothermal method. During this process, absolute ethanol (45 ml) and glycerol (15 ml) were mixed at a volume ratio of 3:1 by magnetic stirring at room temperature. TBT (2ml) was added dropwise, stirred for 10min, transferred to a stainless steel autoclave lined with tetrafluoroethylene, sealed, and kept at 180°C for 30 hours. After naturally cooling to room temperature, the white sediment was collected by centrifugation at 7000 rpm for 5 minutes, and washed 3 times with absolute ethanol. After the white precipitate was completely dried at 60°C, it was calcined in air at 400°C for 5 hours to obtain flower-like titanium dioxide particles.

[0023] 2. Preparation of multi-layered silica-coated titania composite particles: Superhydrophobic titania / silica composite particles were prepared by the improved Stobber method. ...

Embodiment 2

[0027] 1. Preparation of flower-like titanium dioxide particles: layered flower-like titanium dioxide nanoparticles were synthesized by a typical template-free solvothermal method. During this process, absolute ethanol (45 ml) and glycerol (15 ml) were mixed at a volume ratio of 3:1 by magnetic stirring at room temperature. TBT (3ml) was added dropwise, stirred for 10 minutes, transferred to a stainless steel autoclave lined with tetrafluoroethylene, sealed, and kept at 190°C for 28 hours. After naturally cooling to room temperature, the white sediment was collected by centrifugation at 7000 rpm for 5 minutes, and washed 3 times with absolute ethanol. After the white precipitate was completely dried at 60°C, it was calcined in air at 425°C for 4 hours to obtain flower-like titanium dioxide particles.

[0028] 2. Preparation of multi-layered silica-coated titania composite particles: Superhydrophobic titania / silica composite particles were prepared by the improved Stobber meth...

Embodiment 3

[0033] 1. Preparation of flower-like titanium dioxide particles: layered flower-like titanium dioxide nanoparticles were synthesized by a typical template-free solvothermal method. During this process, absolute ethanol (45 ml) and glycerol (15 ml) were mixed at a volume ratio of 3:1 by magnetic stirring at room temperature. TBT (4ml) was added dropwise, stirred for 10 minutes, transferred to a stainless steel autoclave lined with tetrafluoroethylene, sealed, and kept at 200°C for 26 hours. After naturally cooling to room temperature, the white sediment was collected by centrifugation at 7000 rpm for 5 minutes, and washed 4 times with absolute ethanol. After the white precipitate was completely dried at 60°C, it was calcined in air at 450°C for 3 hours to obtain flower-like titanium dioxide particles.

[0034] 2. Preparation of multi-layered silica-coated titania composite particles: Superhydrophobic titania / silica composite particles were prepared by the improved Stobber meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com