Natural latex sponge product as well as preparation method and application thereof

A technology for natural latex and sponge products, applied in the field of natural latex, can solve the problems affecting the product quality and consumer experience of natural latex sponge products, the latex sponge is easy to age, and the contact area is large, so as to achieve suitable large-scale production, excellent mechanical properties and Anti-aging performance, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

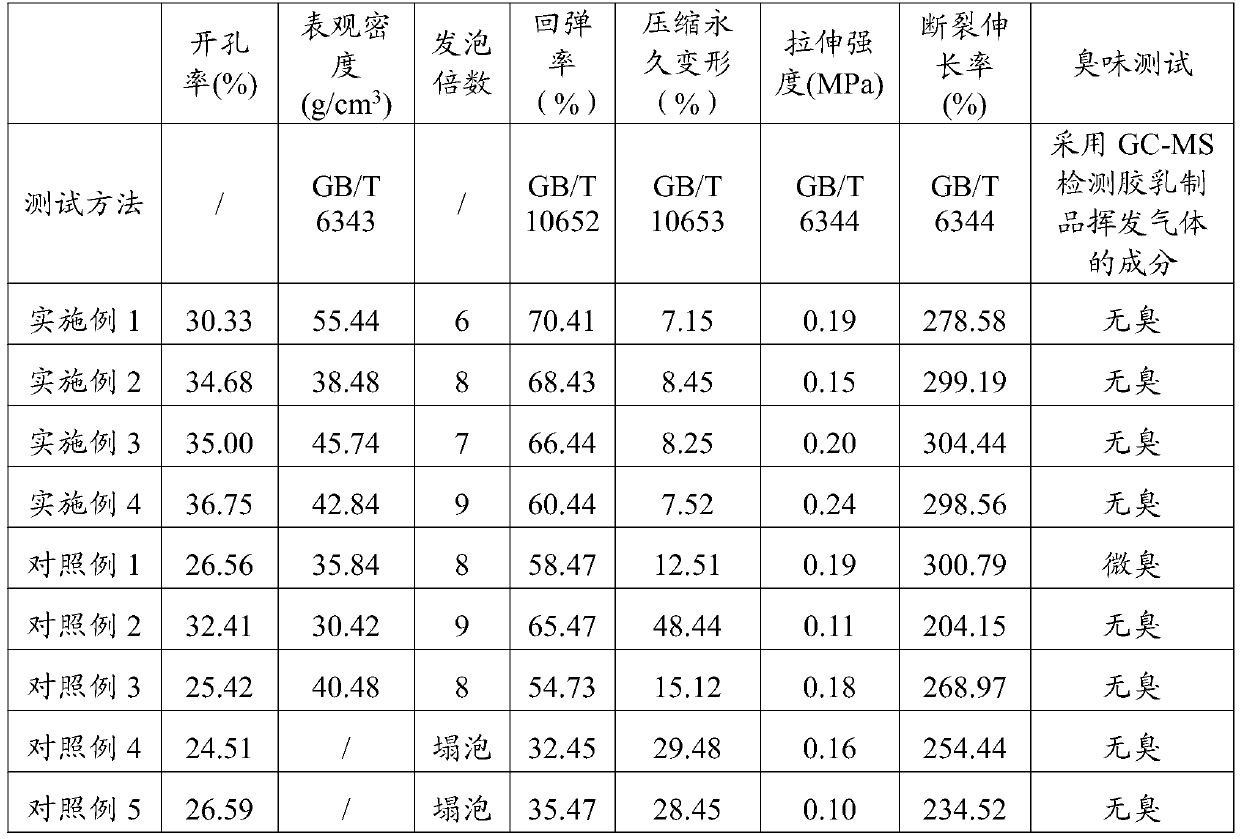

Examples

preparation example Construction

[0051] The present invention provides the preparation method of natural rubber latex sponge product described in above-mentioned technical scheme, comprises the following steps:

[0052] Mix low-protein natural rubber latex, coconut shell activated carbon, compound vulcanization accelerator, and anti-aging agent and then mature to obtain pre-mixed latex;

[0053] Mixing the premixed latex, foaming agent, zinc oxide and gelling agent to obtain foamed latex;

[0054] The foamed latex is sequentially subjected to injection molding, shaping, bactericide treatment and vulcanization to obtain a natural latex sponge product.

[0055] The invention mixes low-protein natural rubber latex, coconut shell activated carbon, composite vulcanization accelerator and anti-aging agent and then matures to obtain premixed latex.

[0056] In the present invention, the composite vulcanization accelerator is preferably used in the form of a composite vulcanization accelerator aqueous solution; the ...

Embodiment 1

[0071] (1) 1kg each of the ZDC accelerator, the MBT accelerator and the DPG accelerator is placed in a ball mill to grind, and deionized water is added to make a 20% aqueous solution of the composite vulcanization accelerator;

[0072] Mix low-protein natural rubber latex (nitrogen content: 0.15wt%, 100kg), composite vulcanization accelerator aqueous solution, and tocopherol (0.5kg), and leave to mature at 35°C for 48 hours to obtain premixed latex;

[0073] (2) Add foaming agent (1kg) and coconut shell activated carbon (0.5kg, particle diameter is 50~200nm, specific surface area is 1500~3000m2) in described premixed latex 2 / g), stirring at a rotating speed of 1200r / min for 90min foaming, stirring for 30min at a rotating speed of 250r / min for uniform foaming, adding zinc oxide (2kg) and gelling agent (0.5kg) at a rotating speed of Stir 45min under the condition of 400r / min, obtain foamed latex;

[0074] (3) Immediately inject the foamed latex when it reaches the gelation poi...

Embodiment 2

[0076] (1) 0.5 kg of the ZDC accelerator, the MBT accelerator and the DPG accelerator are placed in a ball mill for grinding, and deionized water is added to make a 20% aqueous solution of the composite vulcanization accelerator;

[0077] Mix low-protein natural rubber latex (nitrogen content: 0.10wt%, 100kg), composite vulcanization accelerator aqueous solution, and tocopherol (2kg), and leave to mature at 35°C for 24 hours to obtain premixed latex;

[0078] (2) Add foaming agent (1kg) and coconut shell activated carbon (2kg, particle diameter is 50~200nm, specific surface area is 1500~3000m2) in described premixed latex 2 / g), stirring at a rotating speed of 1200r / min for 90min to foam, stirring at a rotating speed of 350r / min for 40min to evenly foam, adding zinc oxide (3kg) and gelling agent (1kg) at a rotating speed of 500r Stir 60min under the condition of / min, obtain foamed latex;

[0079] (3) Immediately inject the foamed latex when it reaches the gelation point, tak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com