Heavy-duty truck emergency brake cargo safety system based on non-Newtonian fluid

A non-Newtonian fluid and heavy-duty truck technology, which is applied in the field of heavy-duty truck emergency brake cargo safety system, can solve the problems of cargo damage to the front, forward movement of cargo, driver safety accidents, etc., to achieve the effect of avoiding safety and ensuring braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

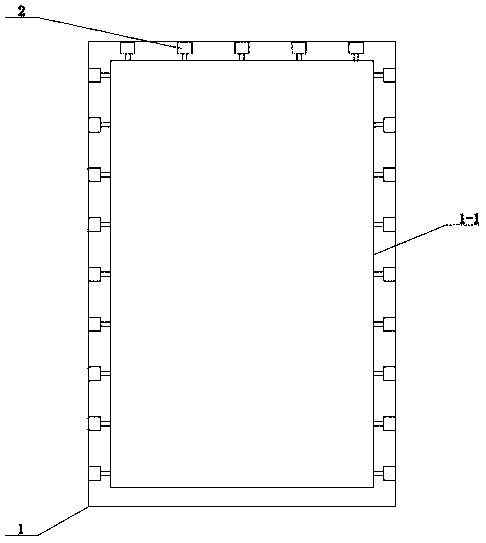

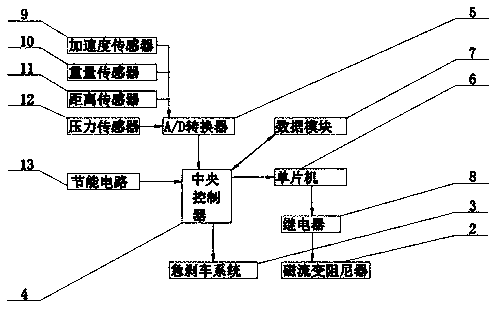

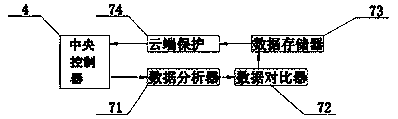

[0024] See Figure 1-Figure 5 As shown, the technical solution adopted in this specific embodiment is: it includes a truck compartment 1, an inner wall 1-1, a guiding wall 1-2, a magnetorheological damper 2, a non-Newtonian fluid emergency braking system 3, and a central controller 4. The converter 5, the single chip microcomputer 6, the data module 7, the relay 8, the acceleration sensor 9, the weight sensor 10, the distance sensor 11, the pressure sensor 12, and the energy-saving circuit 13. The truck compartment 1 includes an inner wall 1-1, A guiding wall 1-2 is arranged on the inner wall 1-1, a pressure sensor 12 is arranged on the guiding wall 1-2, and a plurality of magnetorheological dampers are arranged in the front, left and right walls of the truck compartment 1 2. The weight sensor 10 is installed on the four wheels of the truck. The acceleration sensor 9 and the distance sensor 11 are all installed on the truck body. The acceleration sensor 9, the weight sensor 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com