Bonding experiment tool

An experiment and bonding technology, which is applied in the field of body-in-white connection test and verification, can solve the problems of inaccurate control of the lap gap of test pieces, achieve the effects of improving stability and accuracy, convenient operation, and improving experimental efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

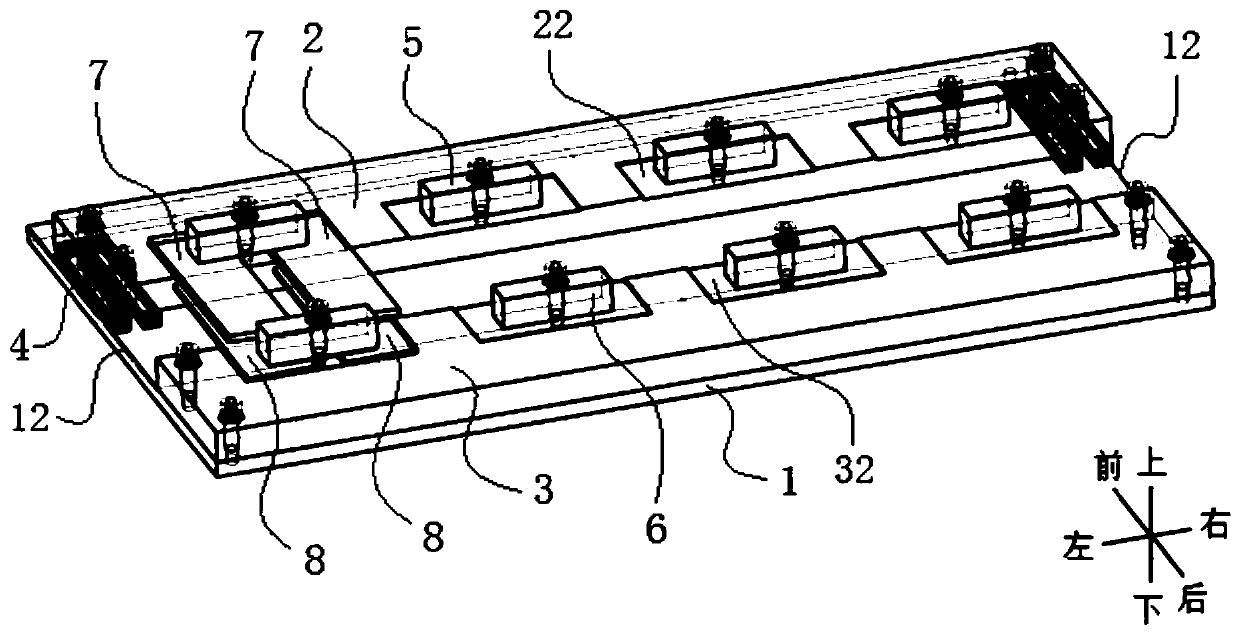

[0019] like Figure 1 to Figure 6 The bonding experiment tooling shown includes a reference plate 1, two upper test pieces 7, two bottom test pieces 8, a first mounting plate 2, a second mounting plate 3, four first pressing blocks 5, four fourth Two briquetting blocks 6 and two sets of gaskets 4.

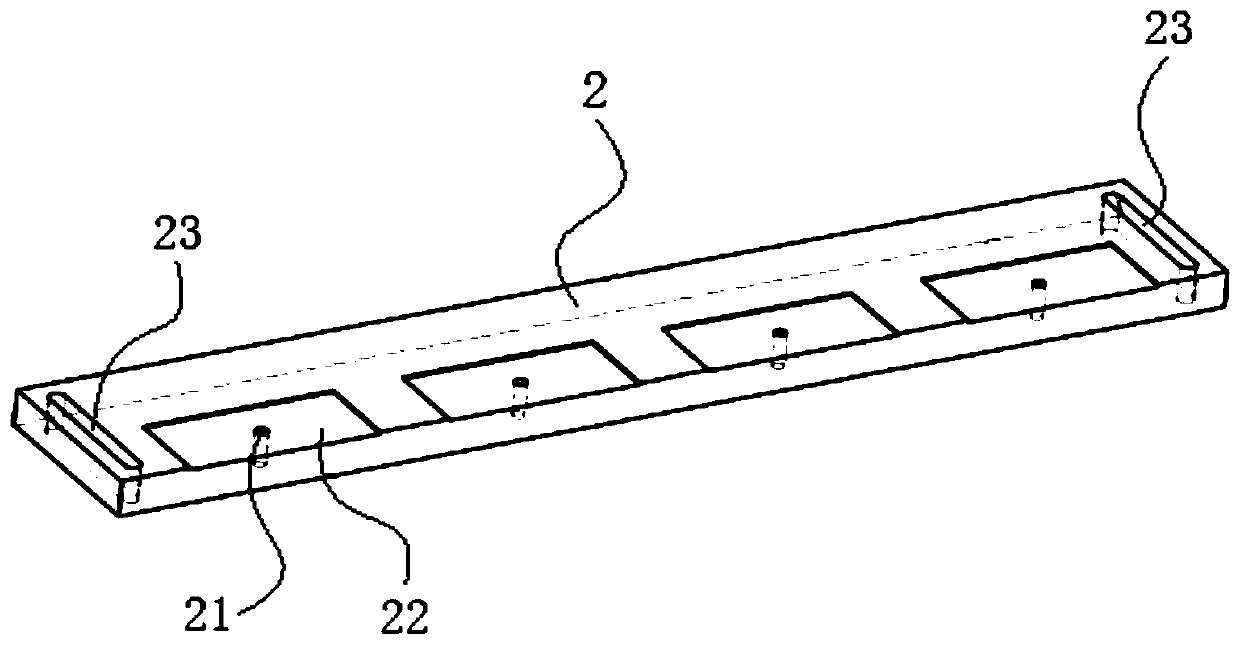

[0020] like figure 2 As shown, the thickness of the first mounting plate 2 and the second mounting plate 3 in the up and down direction are equal, and the rear edge of the upper surface of the first mounting plate 2 is evenly opened with four first square grooves 22 along the left and right directions, and each first The center of the square groove 22 is provided with a first installation hole 21 , and the left end and the right end of the first installation plate 2 are provided with a bar-shaped hole 23 along the front and rear directions.

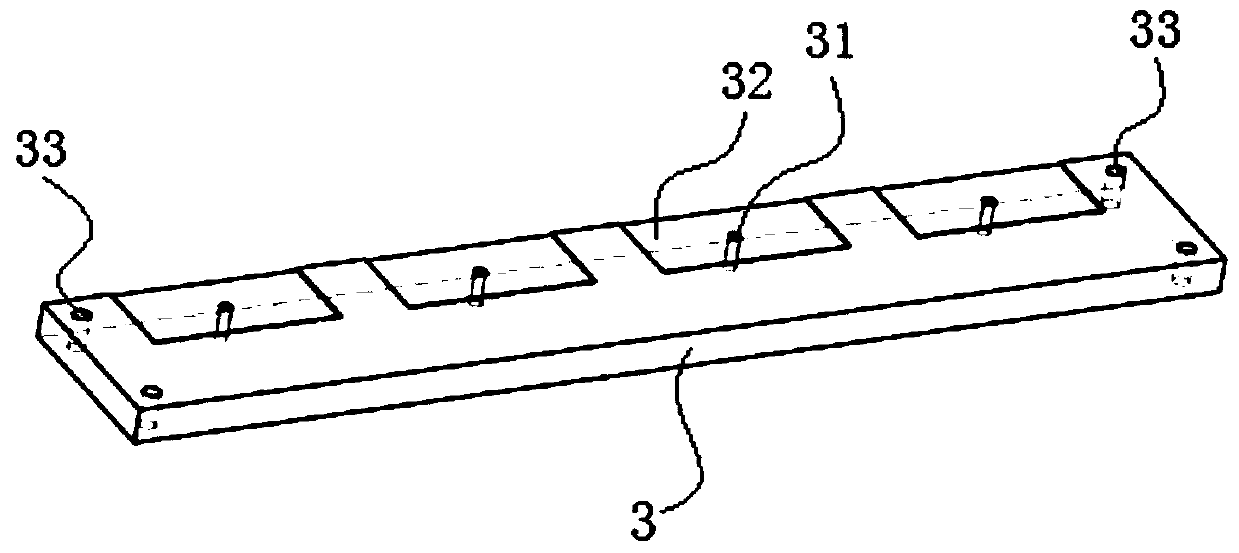

[0021] like image 3 As shown, the front edge of the upper surface of the second mounting plate 3 is evenly provided with four second squ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com