Surface grinder for grinding carbon fiber product

A technology of surface grinder and carbon fiber, which is applied in the direction of machine tools, grinders, and grinding beds suitable for grinding workpiece planes, and can solve the problems of greater physical injury to workers, affecting grinding efficiency, and adjustment of the distance between grinding discs, etc. , to achieve the effect of improving the quality of grinding, quick adjustment and operation, and good grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

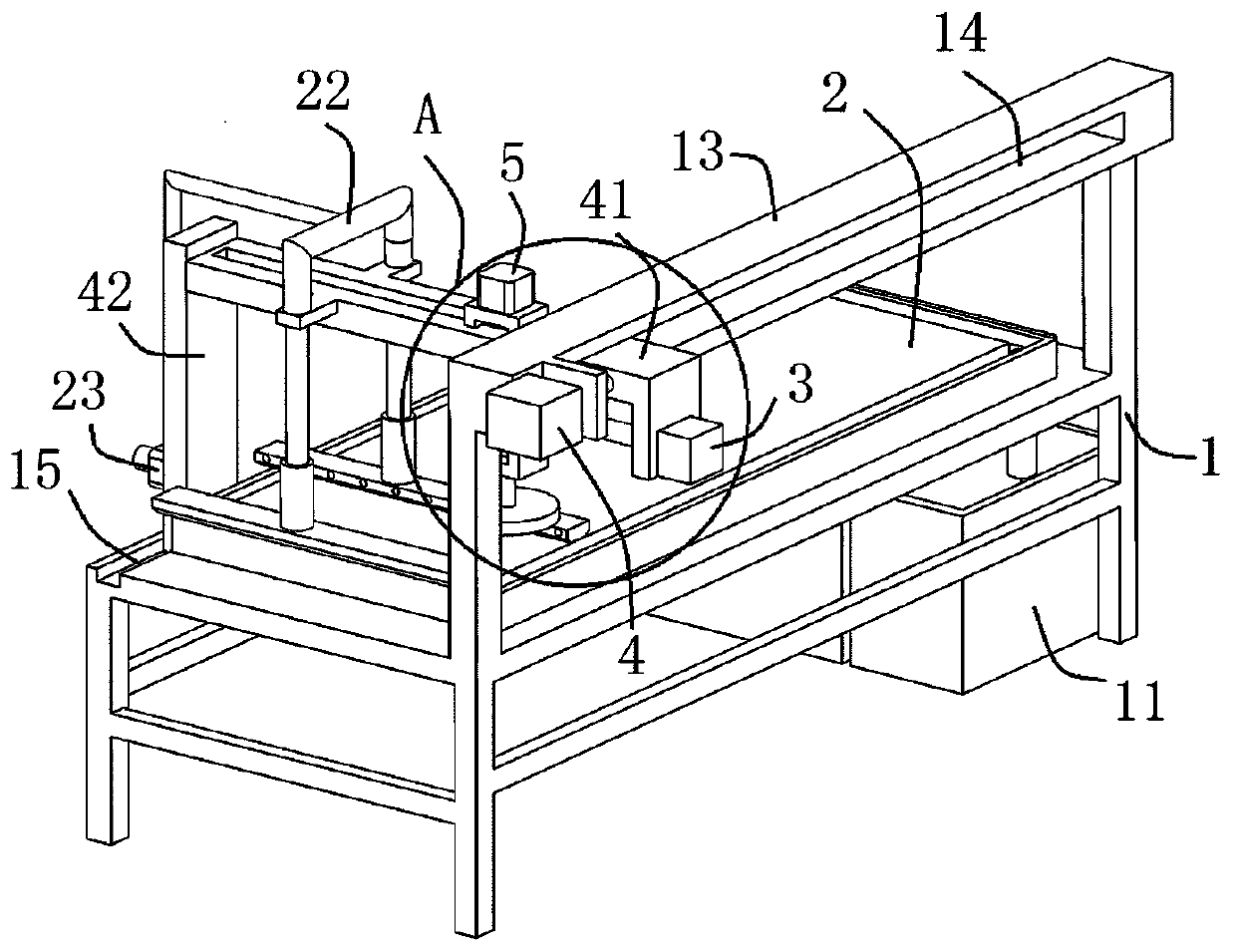

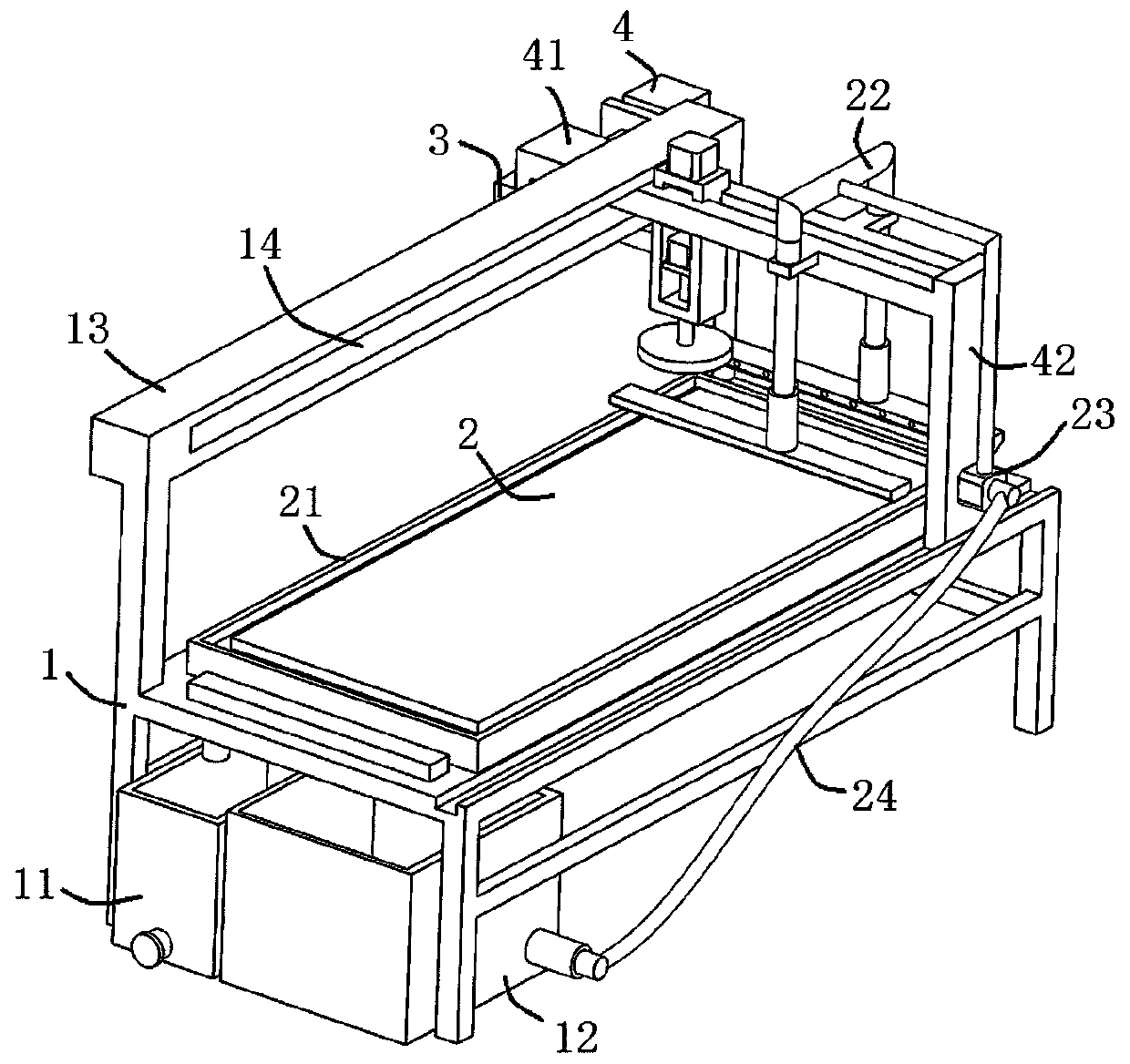

[0028] Embodiment: This embodiment implements adjustable grinding for multiple regions of carbon fiber products, the overall adjustment operation is convenient, and the grinding quality is good; for details, see Figure 1-6 , a surface grinder for grinding carbon fiber products, including a frame 1, a mounting frame 13, a first moving mechanism, a second moving mechanism, and a spraying mechanism, wherein the frame 1 is a table-shaped table with four poles at the bottom , the top of the frame 1 is horizontally provided with a top plate, a rectangular mounting frame 13 is longitudinally provided on one side of the top plate, and the top cross bar of the mounting frame 13 is provided with a moving hole 14 along the length direction; The peripheral plate 21 of the peripheral plate 21 is provided with a rectangular plate-shaped workbench 2 on the top plate in the peripheral plate 21, and the gap left between the workbench and the peripheral plate 21 forms a flow channel, which is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com