Latex disc separator with self-deslagging structure

A disc separator and latex technology, which is applied in the field of natural latex and synthetic latex separation, can solve the problems of unconsidered, easy to generate gel, and untimely heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Combine below Figure 1-12 The present invention will be further described with specific embodiments.

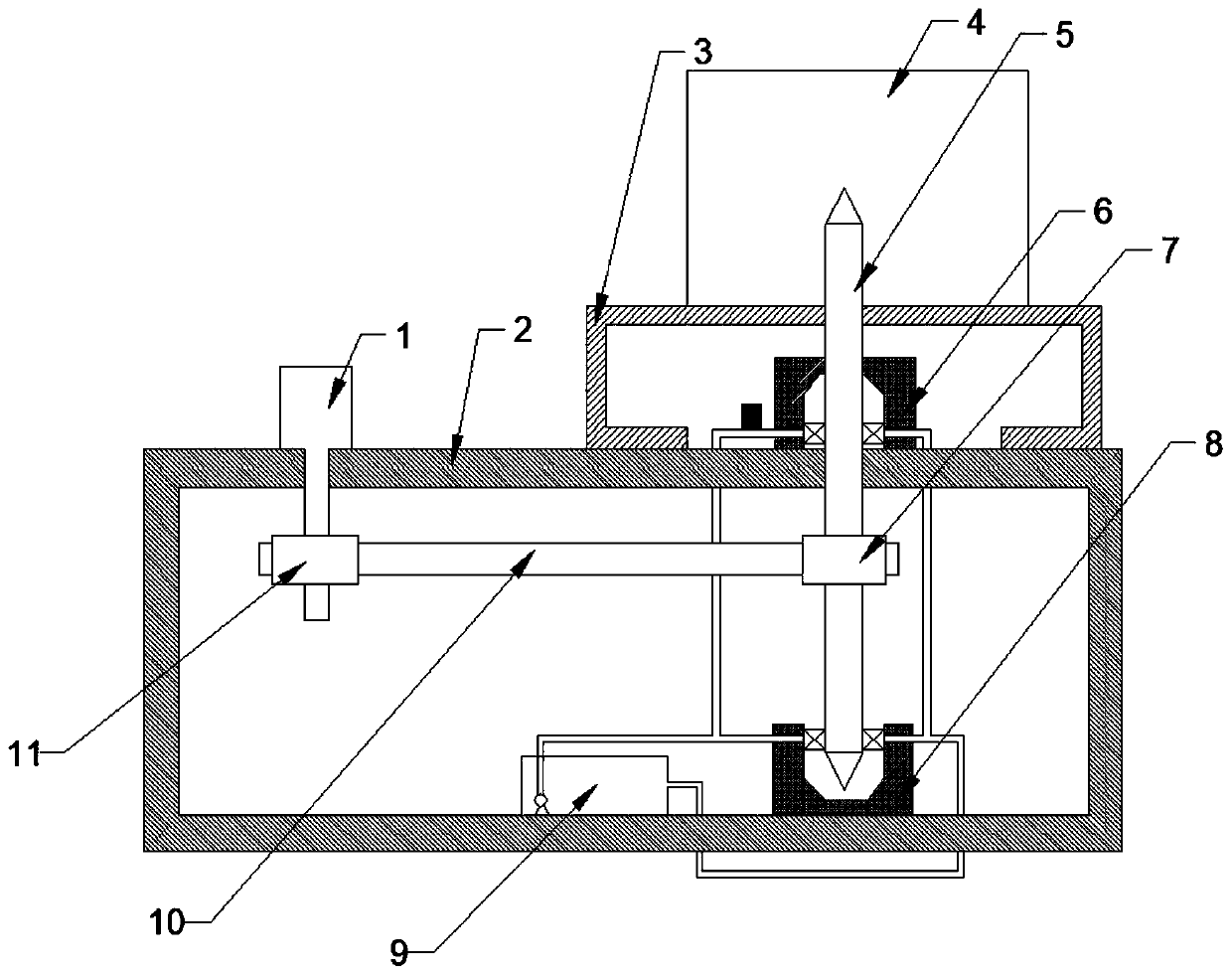

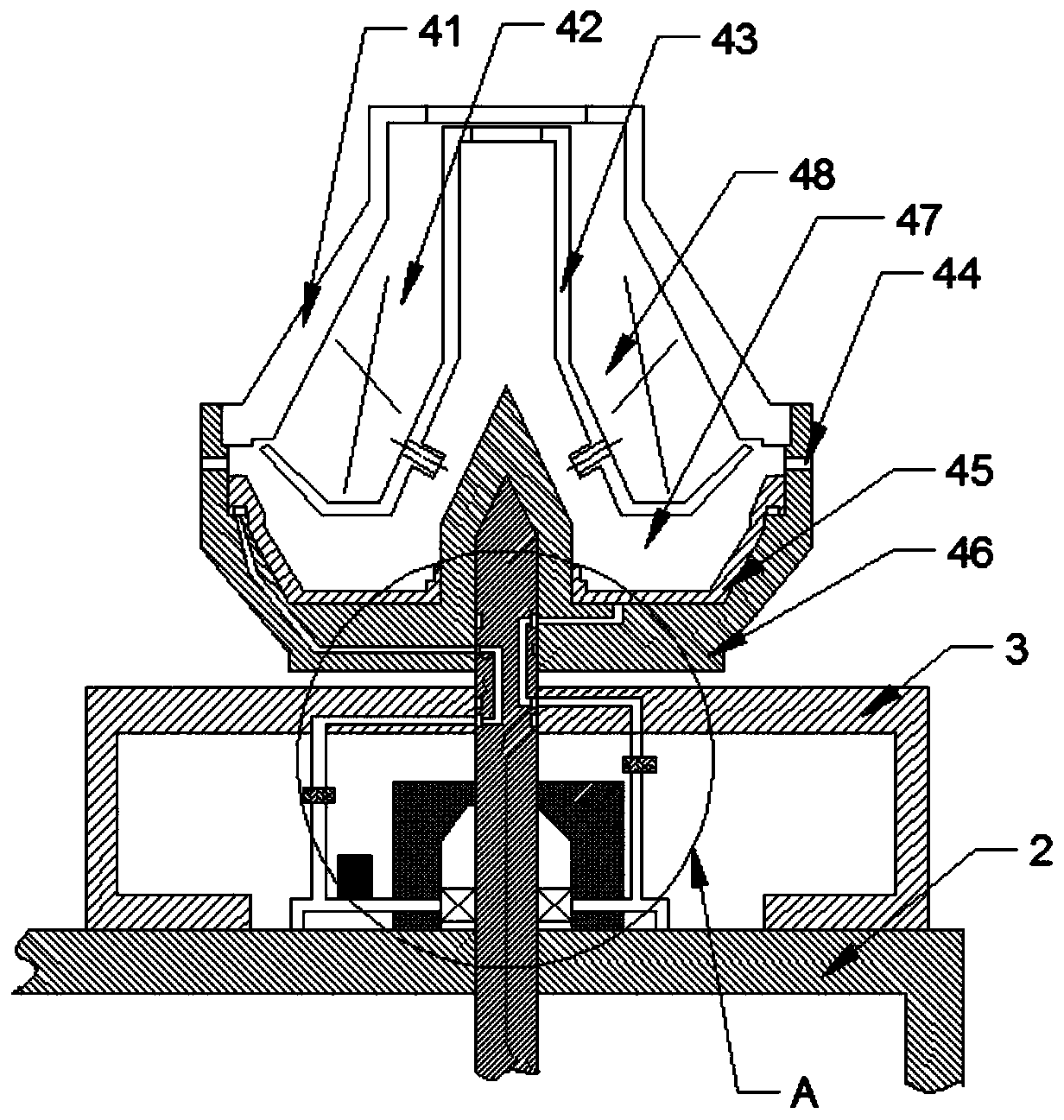

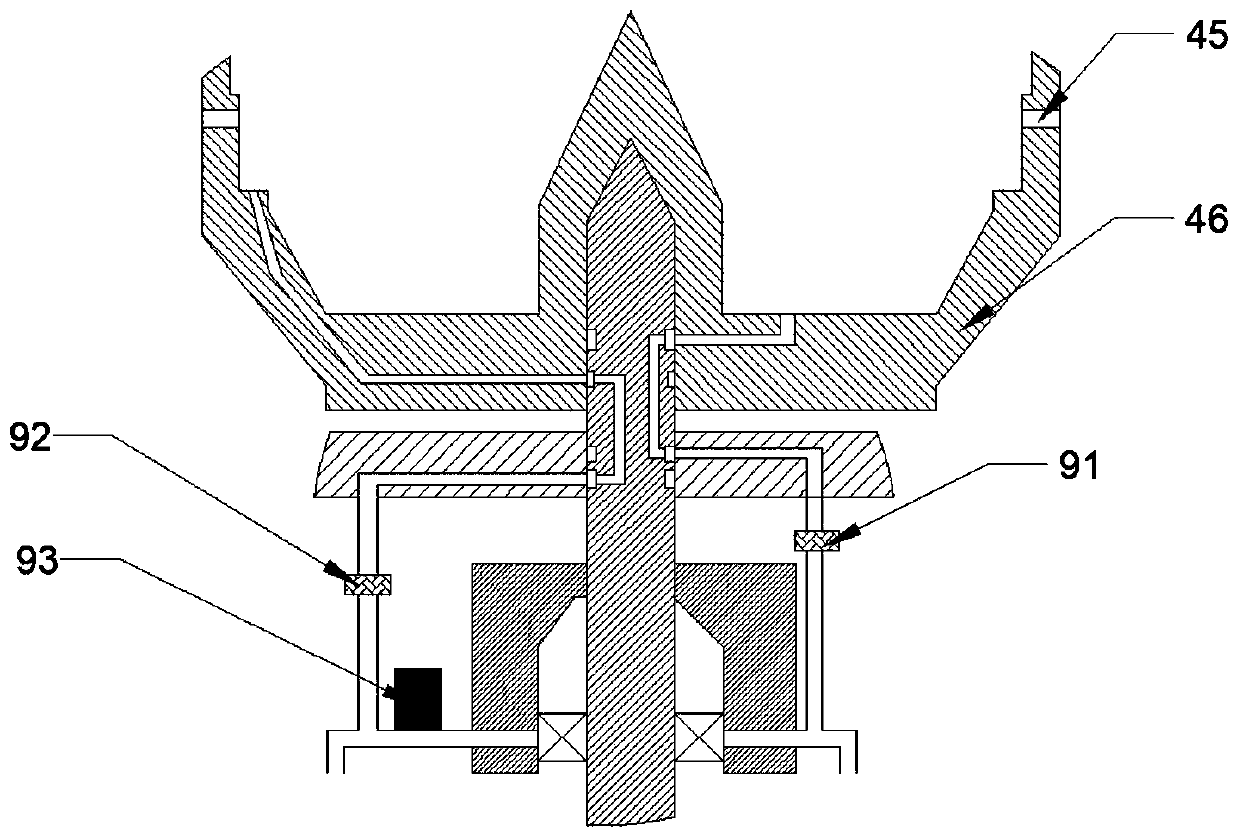

[0047] A latex disc separator with a self-discharging structure, the disc separator includes a motor 1, a lower body 2, an upper body 3, a centrifugal separation structure 4, a transmission device, a vertical shaft 5, an upper bearing 6, Lower bearing 8, lubrication system 9; the motor 1 drives the vertical shaft 5 to rotate through the transmission device, and the vertical shaft 5 drives the centrifugal separation structure 4 to rotate to realize latex separation; the upper bearing 6 and the lower bearing 8 are respectively It is arranged at both ends of the vertical shaft 5 to support the rotation of the vertical shaft 5; the lubrication system 9 provides circulating lubricating oil for the upper bearing 6 and the lower bearing 8 to realize the lubrication and cooling of the bearings; the A temperature detection device 93 is provided on the lubricating system 9, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com