Citrate-based plasticizer and resin composition containing same

A technology of citric acid esters and resin compositions, applied in the direction of organic chemistry, can solve the problems of complex preparation process and difficult commercialization, and achieve the effects of excellent physical properties, excellent plasticizing efficiency, and excellent quality reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The preparation method of citrate plasticizer

[0053] According to one embodiment of the present invention, the citrate plasticizer may be obtained by direct esterification of citric acid and alcohol, or by transesterification of a compound represented by Formula 1 below with alcohol.

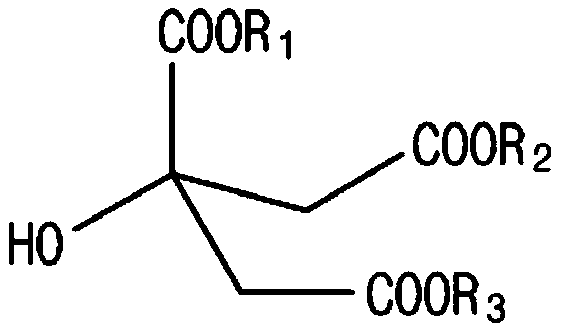

[0054] [Formula 1]

[0055]

[0056] In formula 1, R 1 to R 3 each independently is an alkyl group having 7 carbon atoms.

[0057] More specifically, in the case of preparing a citrate-based plasticizer comprising a compound of formula 1-1 or formula 1-2, direct esterification reaction can be applied, and can be carried out using citric acid and n-heptanol or 2-methanol The direct esterification reaction of hexanol. In other words, as a preparation method of non-mixed citrate, direct esterification reaction can be carried out, and in the case of preparing citrate plasticizers containing compounds of formula 1-1 and formula 1-2, separate preparation of and a way to mix them.

...

preparation Embodiment 1

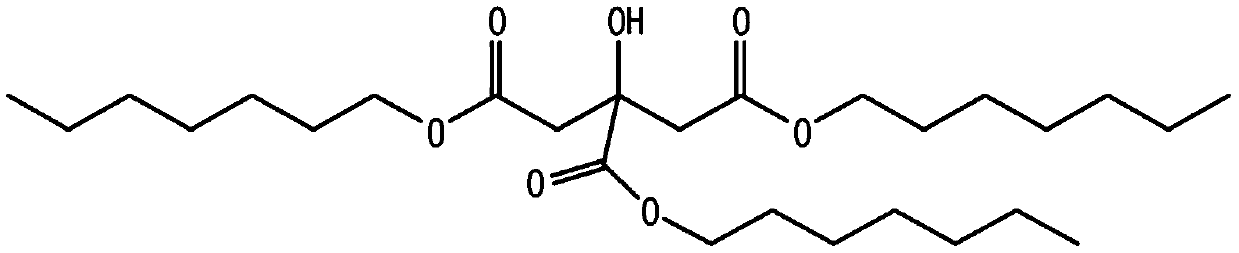

[0091] Preparation Example 1: Preparation of Tris(n-heptyl) Citrate (THC)

[0092]Into a 3-liter four-neck reactor equipped with a cooler, water stripper, condenser, decanter, reflux pump, temperature controller and stirrer was charged 576 g of isolated 2-hydroxypropane-1,2,3 -tricarboxylic acid (citric acid), 1,566 g of n-heptanol (Aldrich) (molar ratio 1:4.5) and 1.44 g (0.25 parts by weight based on 100 parts by weight of citric acid) of titanium-based catalyst (TnBT , tetra-n-butyl titanate), and then slowly increase the temperature to about 170°C. At about 170°C, water started to be generated, and the esterification reaction was carried out for about 4.5 hours at a reaction temperature of about 220°C under atmospheric pressure while continuously feeding nitrogen. When the acid value reaches 0.1, the reaction ends.

[0093] After the reaction is over, distillation extraction is performed under reduced pressure for 0.5 hours to 4 hours to remove unreacted raw materials, t...

preparation Embodiment 2

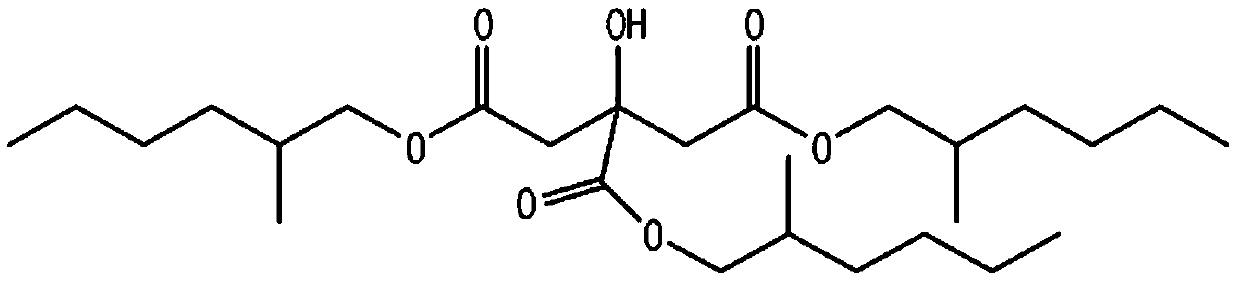

[0094] Preparation Example 2: Preparation of Tris(2-methylhexyl) Citrate (TiHC)

[0095] Except that 2-methylhexanol was used instead of n-heptanol in Preparation Example 1, the same reaction method as in Preparation Example 1 was carried out to finally obtain 1,435 g (yield: 98%) of tris(2- Methylhexyl) ester (TiHC).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com