Organic anode used for sodium carbon dioxide battery and manufacturing method thereof, and sodium carbon dioxide battery

A technology of carbon dioxide and organic electrolyte, applied in the direction of fuel cell half-cells and secondary battery-type half-cells, battery electrodes, fuel cells, etc. Liquid is easy to volatilize and other problems, to achieve the effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

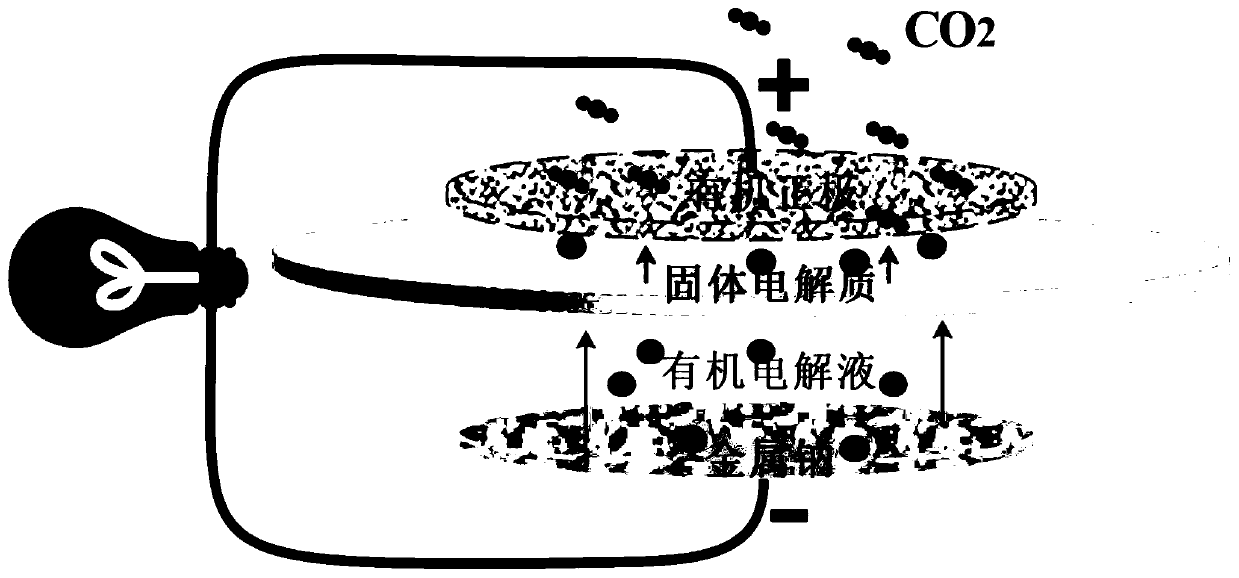

[0037] Such as figure 1 As shown, a sodium carbon dioxide battery based on an organic cathode includes: stacked metal sodium, an organic electrolyte, a solid electrolyte, and an organic cathode.

[0038] Among them, the negative electrode is a metal sodium block with a thickness of 0.6mm and an area of 0.785cm 2 , the organic electrolyte is 1mol / LNaClO 4 / [(EC+DMC)(1:1)+l vol%FEC], solid electrolyte thickness is 1mm, NASICON solid electrolyte diaphragm with a diameter of 16mm, organic positive electrode includes carbon nanotubes, activated carbon, polytetrafluoroethylene, 1mol / L NaClO 4 / [(EC+DMC)(1:1)+l vol%FEC], mixed according to solid-liquid ratio 15mg:5mg:0.1mg:2ml, ultrasonicated for 12 hours, centrifuged at 10000rpm for 5 minutes, vacuum dried at 80°C for 12 hours, and evenly coated Prepared on carbon paper with a loading of 3.0 mg / cm 2 .

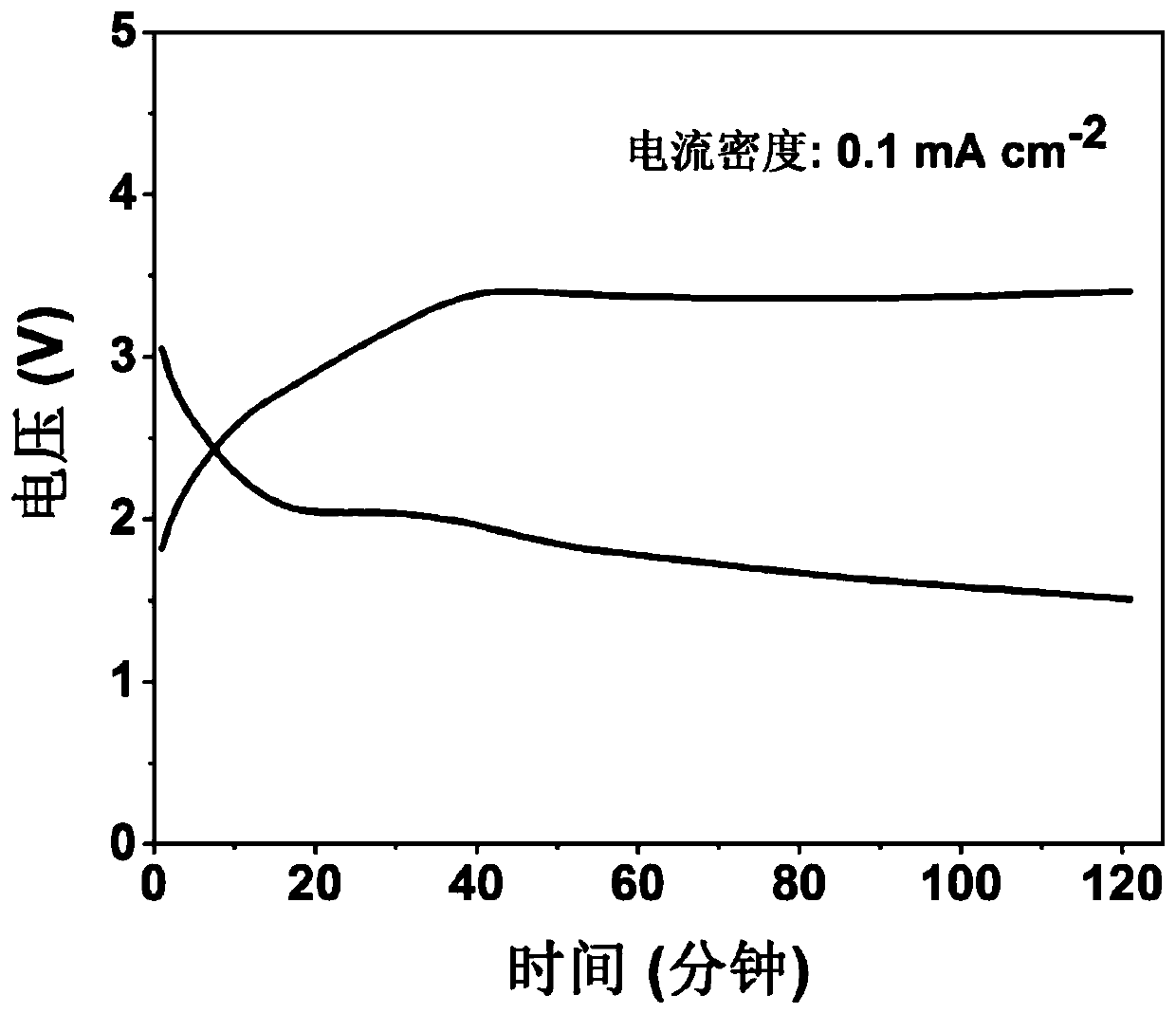

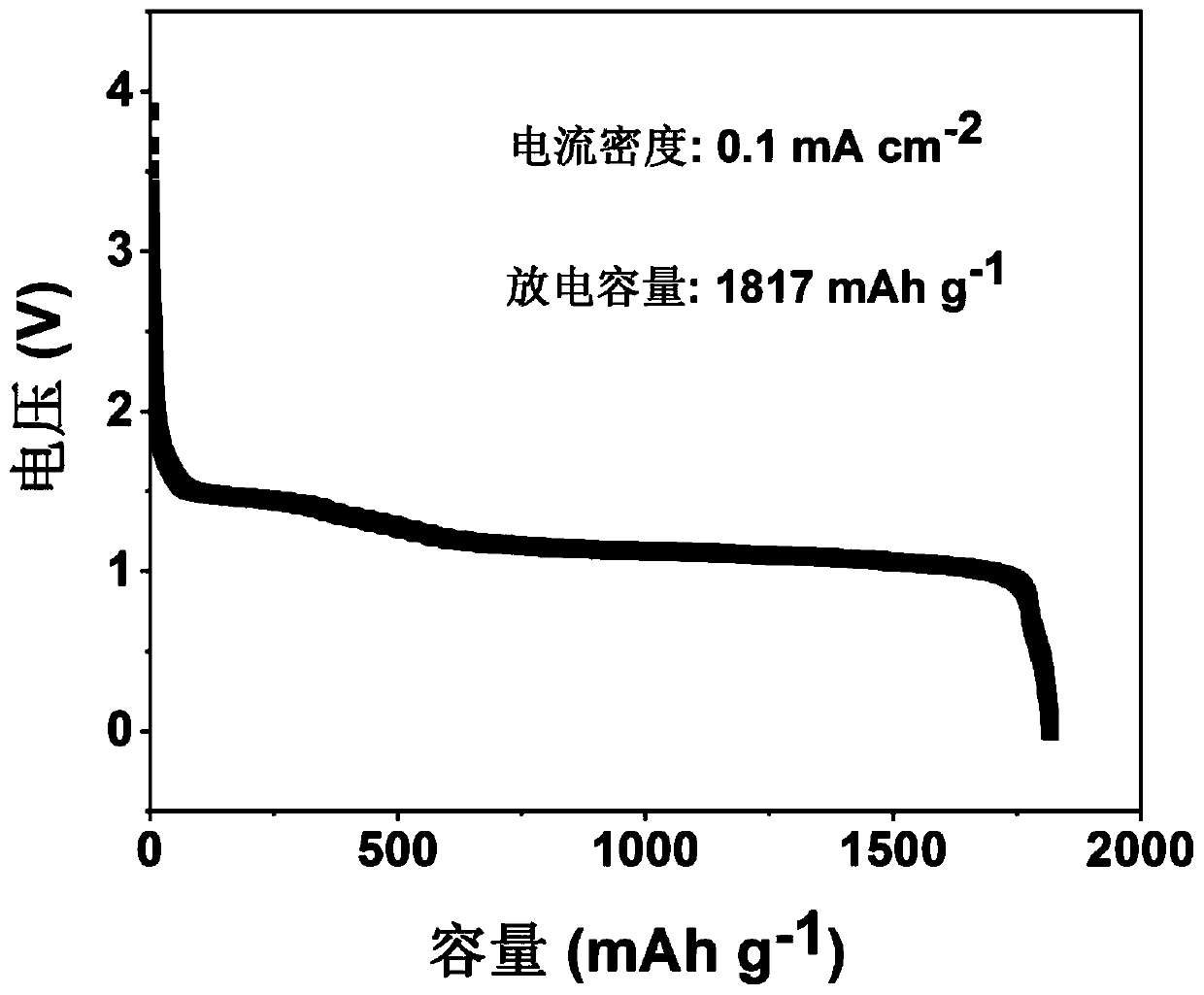

[0039] The sodium carbon dioxide battery assembled in this example is in pure CO at 30°C 2 The charge and discharge perfor...

Embodiment 2

[0041] Such as figure 1 As shown, a sodium carbon dioxide battery based on an organic cathode includes: stacked metal sodium, an organic electrolyte, a solid electrolyte, and an organic cathode.

[0042] Among them, the negative electrode is a metal sodium block with a thickness of 0.5mm and an area of 0.785cm 2 , the organic electrolyte is 1mol / LNaClO 4 / [(EC+DMC)(1:1)+l vol%FEC], the thickness of the solid electrolyte is 0.8mm, the diameter of the NASICON solid electrolyte diaphragm is 16mm, and the organic positive electrode includes carbon nanohorns, activated carbon, polytetrafluoroethylene, 1mol / L NaClO 4 / [(EC+DMC)(1:1)+l vol%FEC], mixed according to solid-liquid ratio 10mg:5mg:0.1mg:1.5ml, ultrasonicated for 10 hours, centrifuged at 10000rpm for 10 minutes, vacuum dried at 80°C for 18 hours, and evenly coated Prepared by covering on carbon paper, the loading capacity is 3.5mg / cm 2 .

[0043] The sodium carbon dioxide battery assembled in this example is in pure ...

Embodiment 3

[0045] Such as figure 1 As shown, a sodium carbon dioxide battery based on an organic cathode includes: stacked metal sodium, an organic electrolyte, a solid electrolyte, and an organic cathode.

[0046] Among them, the negative electrode is a metal sodium block with a thickness of 0.7mm and an area of 0.785cm 2 , the organic electrolyte is 1mol / LNaClO 4 / [(EC+DMC)(1:1)+l vol%FEC], the thickness of the solid electrolyte is 0.8mm, the diameter of the NASICON solid electrolyte separator is 16mm, and the organic positive electrode includes 40% Pt / C, activated carbon, polytetrafluoroethylene , 1mol / L NaClO 4 / TEGDME, mixed according to the solid-liquid ratio of 20mg:5mg:0.1mg:2.0ml, sonicated for 10 hours, centrifuged at 10000rpm for 10 minutes, vacuum-dried at 80°C for 48 hours, and evenly coated on carbon paper, with a loading capacity of 3.0mg / cm 2 .

[0047] The sodium carbon dioxide battery assembled in this example is in pure CO at 30°C 2 The charge and discharge perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com