Perovskite quantum dot film and preparation method thereof, and device

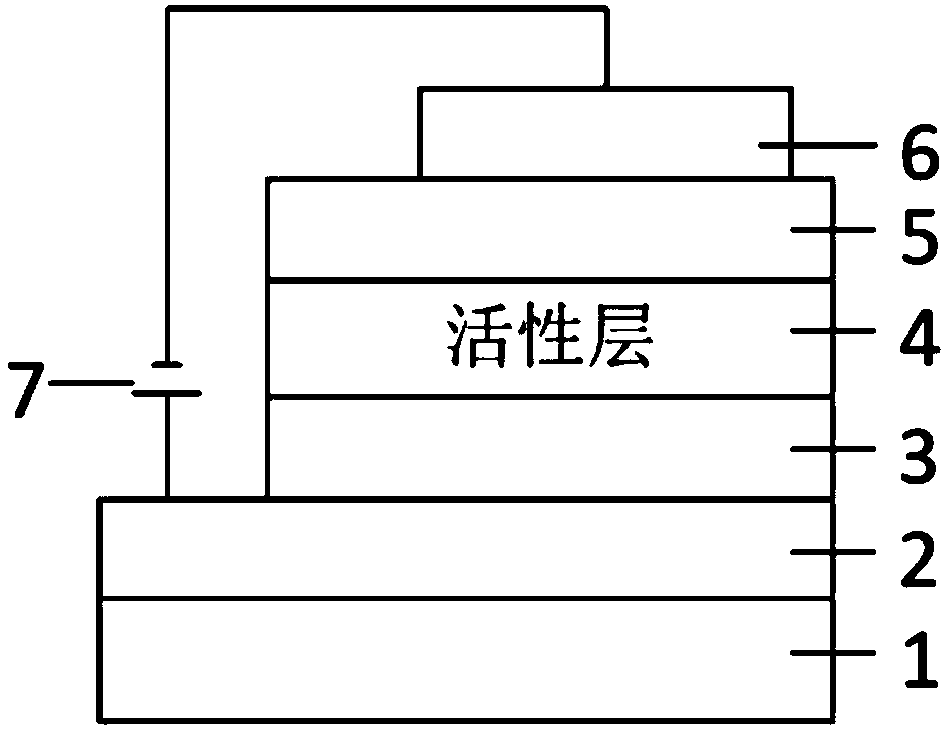

A thin-film preparation and perovskite technology, which is applied in the fields of electric solid-state devices, semiconductor devices, semiconductor/solid-state device manufacturing, etc., can solve the problems of high roughness of perovskite films, low device efficiency, and agglomeration of quantum dots, and achieve luminescence. Adjustable wavelength, improved conductivity, and good film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1 Preparation of in-situ growth perovskite quantum dot material.

[0044] Will C 8 h 19 N(octylamine), CH 3 NH 2 Br(MABr) and PbBr 2 The precursor solution was formulated at a molar ratio of 1:1.5:0.625, and the anti-solvent was mixed with isopropanol (IPA) and n-butanol (NBA) at a volume ratio of 5:3. The precursor solution was spin-coated on the PVK substrate, and the anti-solvent was added dropwise during the spin-coating process to accelerate the film formation of the perovskite film, and the perovskite quantum dot film was obtained after annealing.

[0045] Such as image 3 As shown, the photoluminescence peaks of this quantum dot film are respectively located at 473nm and 474nm before and after annealing, and have ideal thermal stability. Figure 4 The surface morphology (AFM) of the film shows that this kind of quantum dot perovskite material has good film-forming property (RMS=7.4nm).

Embodiment 2

[0046] Example 2 Preparation of in-situ growth perovskite quantum dot material.

[0047] Will C 5 h 13 N(amylamine), C 8 h 19 N(octylamine), CH 3 NH 2 Br(MABr) and PbBr 2 The precursor solution was formulated at a molar ratio of 0.2:0.8:1.5:0.625, and the anti-solvent was mixed with isopropanol (IPA) and n-butanol (NBA) at a volume ratio of 5:3. The precursor solution was spin-coated on the PVK substrate, and the anti-solvent was added dropwise during the spin-coating process to accelerate the film formation of the perovskite film, and the perovskite quantum dot film was obtained after annealing.

[0048] As shown in Table 1, the perovskite quantum dot film can achieve a photoluminescence quantum efficiency (PLQE) of 71.1% under the optimized film-forming conditions such as PVK rotation speed, perovskite rotation speed and anti-solvent addition time.

[0049] Table 1 Effect of preparation process on photoluminescence quantum efficiency of perovskite quantum dot film

...

Embodiment 3

[0051] Example 3 Preparation of traditional perovskite quantum dot materials and light-emitting devices.

[0052] Figure 5 Shown is the traditional method for preparing perovskite quantum dots: using long-chain ligands, reprecipitation method to obtain MAPbBr 3 Preparation process of quantum dots. With THF as anti-solvent, Pb(Ac) 2 , OA and stearylamine were added into THF at a molar ratio of 2.6:2.5:1 and stirred to form a precursor solution for later use. MABr was dissolved in DMF and then slowly added dropwise to the above precursor solution to react to form a quantum dot solution, which was transferred to a centrifuge tube and centrifuged several times at high speed with isopropanol to obtain clarified quantum dots. The quantum dot solution was spin-coated on the PEDOT:PSS / PVK substrate, and the perovskite quantum dot film was obtained after annealing.

[0053] The surface of this kind of quantum dot perovskite material is rough, and it is difficult to obtain a relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com