Integrated light-emitting Micro LED chip and manufacturing method thereof

A manufacturing method and chip technology, which can be applied to electrical components, electrical solid-state devices, circuits, etc., can solve problems such as lattice mismatch and thermal mismatch, and achieve the effects of improving thermal matching, increasing efficiency, and reducing complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

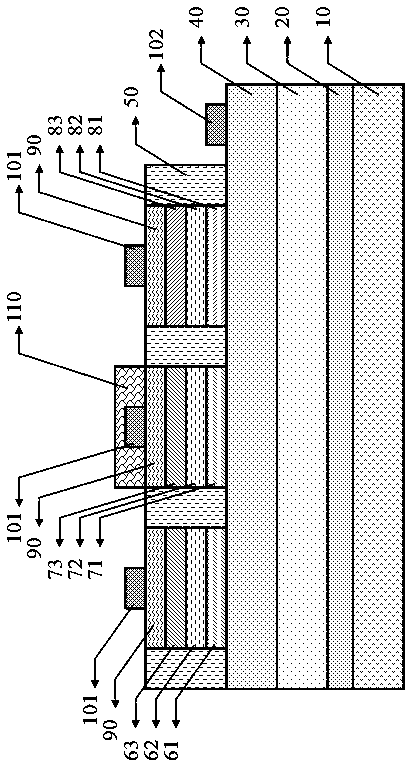

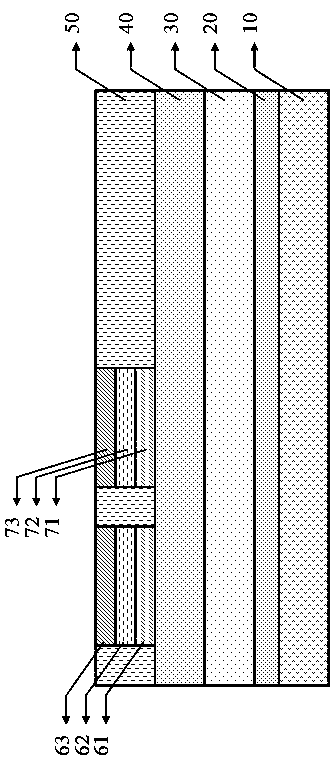

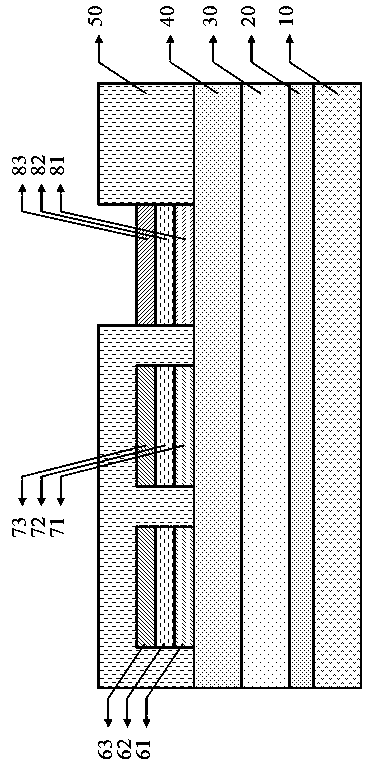

[0049] 1. Production steps:

[0050] 1. A substrate 10 is provided, which may be any one of sapphire, silicon, silicon carbide, and gallium nitride, but is not limited thereto.

[0051] 2. In the MOCVD machine, the buffer layer 20 , the unintentionally doped GaN layer 30 and the n-type doped GaN layer 40 are epitaxially grown on the substrate 10 in sequence by using the conventional LED epitaxial growth technology.

[0052] 3. Deposit the insulating dielectric mask layer 50 on the n-type doped GaN layer 40 for the first time by means of plasma enhanced chemical vapor deposition, and then fabricate the first blue photoelectric sensor on the surface of the insulating dielectric mask layer 50 by photolithography. The light-emitting structure layer and the second blue light-emitting light-emitting structure layer area mask, the width of the mask area is between 1 and 100 μm, and the first blue light-emitting structure layer is etched laterally and at intervals by chemical etching ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com