Chuck table

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

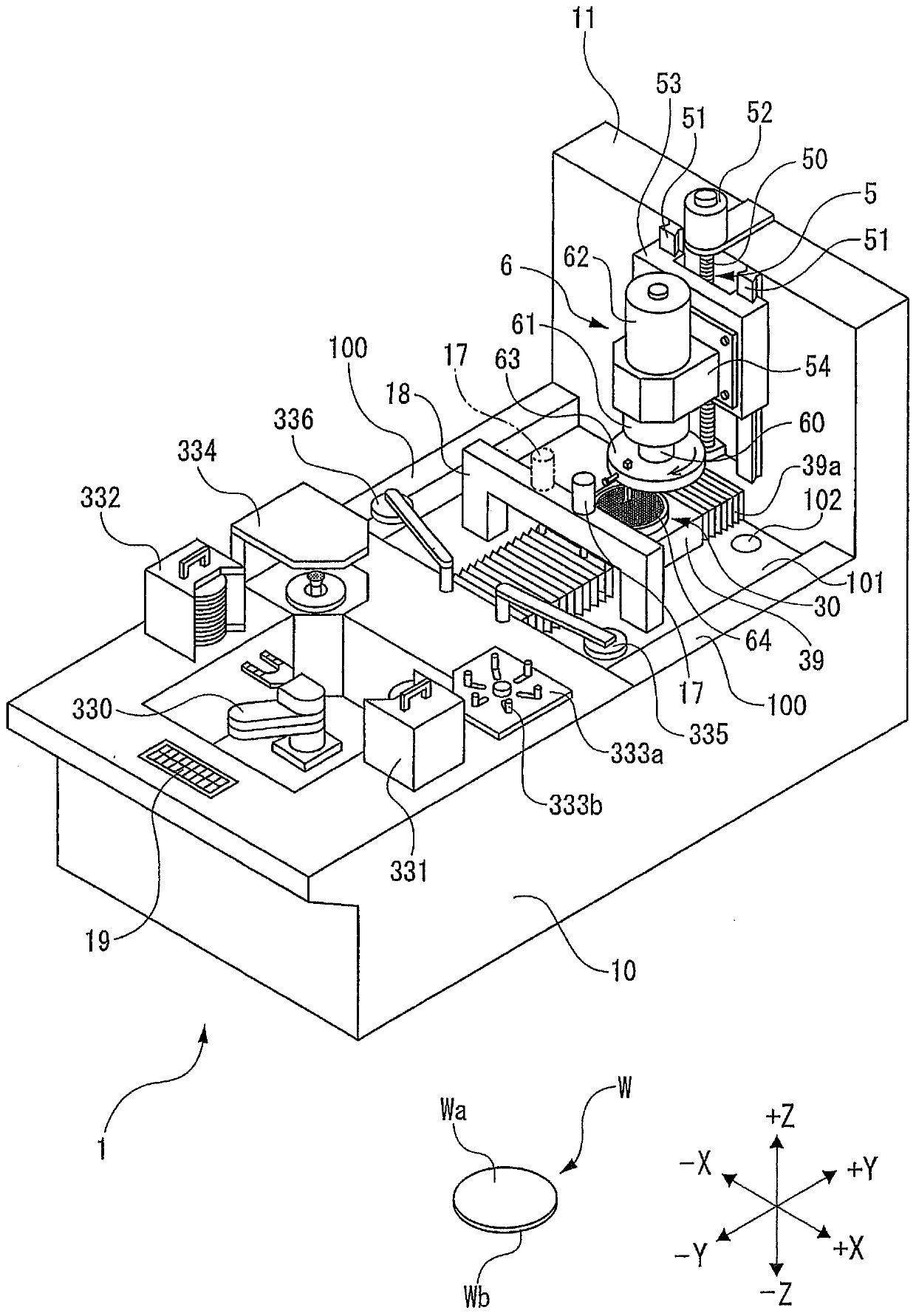

[0025] figure 1 The machining apparatus 1 shown is an apparatus for turning a plate-shaped workpiece W held on a chuck table 30 of the present invention by a tool turning unit 6 having a tool tool 64 . The front side (-Y direction side) on the base 10 of the processing device 1 is used as an area for loading and unloading the plate-shaped workpiece W with respect to the chuck table 30, and the rear side (+Y direction side) on the base 10 is used as an area for turning the workpiece W by a tool. The unit 6 is an area where the turning process of the plate-shaped workpiece W held on the chuck table 30 is performed.

[0026] figure 1 The illustrated plate-shaped workpiece W is, for example, a semiconductor wafer having a circular outer shape with silicon as a base material, but is not limited thereto. In addition, the upper surface Wa of the plate-shaped workpiece W serves as a surface to be processed by turning. The lower surface Wb of the plate-shaped workpiece W is protecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com