Etching method of sic substrate

A substrate and by-product technology, applied in the field of SiC substrate etching, can solve the problems of increasing the difficulty and workload of production and maintenance, and affecting the yield of products, so as to prolong the cleaning and maintenance cycle, reduce the difficulty and workload of maintenance, Possible effect of reducing deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

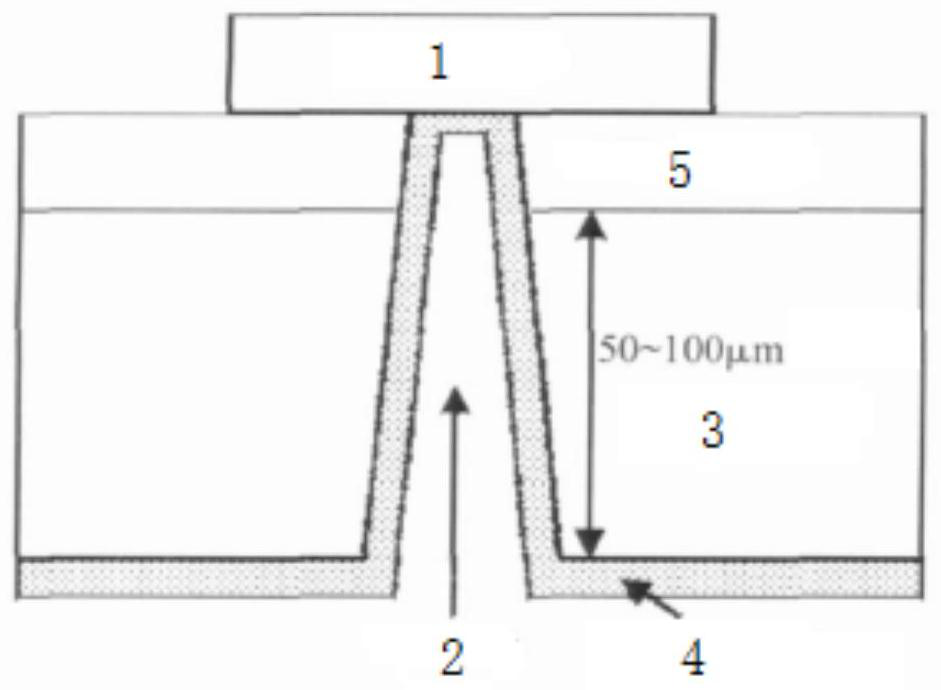

Image

Examples

Embodiment

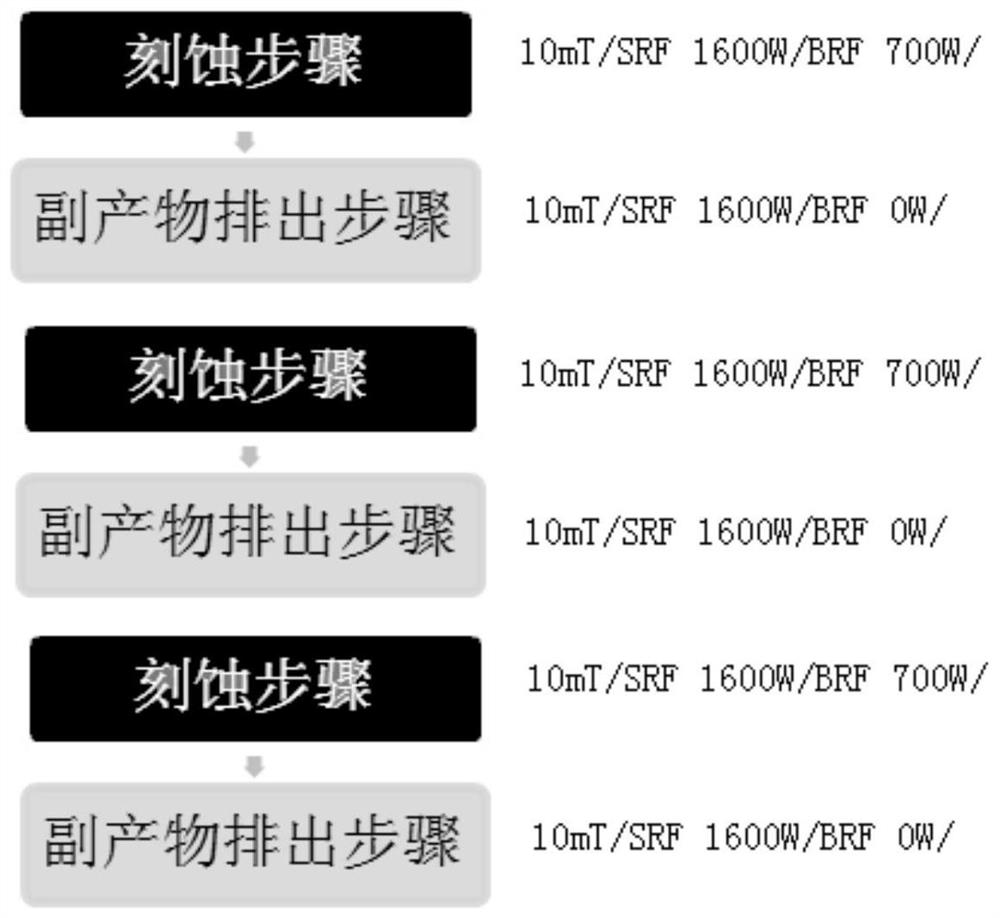

[0039] figure 2 A flowchart showing a method of etching a SiC substrate according to an exemplary embodiment of the present invention. The etching method of the SiC substrate alternately performs the etching step and the by-product discharge step, in the etching step, the SiC substrate provided in the reaction chamber is etched; in the by-product discharge step, the reaction in the reaction chamber is discharged The processes of the by-product, etching step and by-product discharge step are as follows:

[0040] Etching steps: 10mT / SRF 1600W / BRF 700W / 100SF 6 +30O 2 +20Ar / 10s, that is, the pressure of the reaction chamber is 10mT, the RF power of the upper electrode is 1600W, the RF power of the lower electrode is 700W, and the flow rate of the process gas is sulfur hexafluoride (SF 6 ) 100sccm, oxygen (O 2 ) 30sccm, argon (Ar) 20sccm, the duration is 10s;

[0041] By-product discharge steps: 10mT / SRF 1600W / BRF 0W / 150Ar / 1s, that is, the pressure of the reaction chamber is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com