A Blasting Treatment Method for Double Layer Overlapping Goaf

A treatment method and goaf technology, applied in blasting and other directions, can solve problems such as low efficiency and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

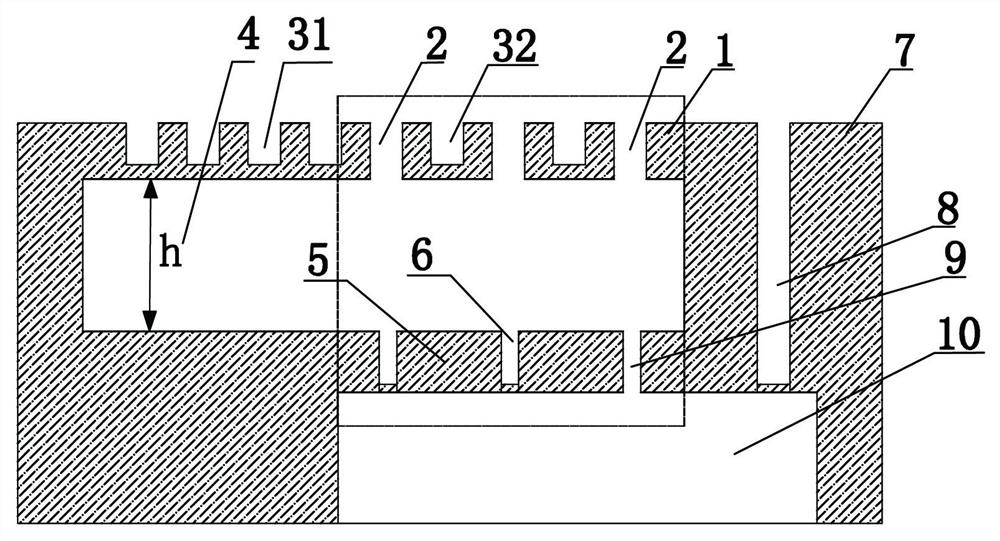

[0033] The rock mass in the double-layer goaf is mainly composed of phyllite with a rock density of 1300-1800kg / m 3 , the Platts firmness coefficient is 10, the length of the upper roof in the upper goaf is 100 m, the width is 50 m, the thickness of the roof is 11-20 m, the length of the lower roof is 150 m, the width is 80 m, the thickness of the lower roof is 10-16 m, the upper roof and The height between the lower roof slabs is 35 m.

[0034] Concrete process implementation steps are as follows:

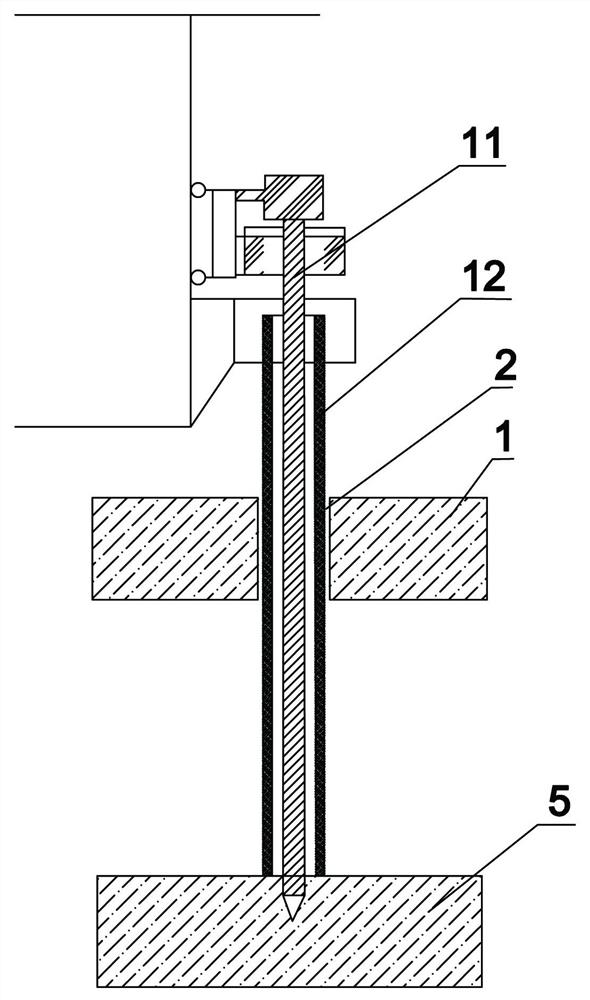

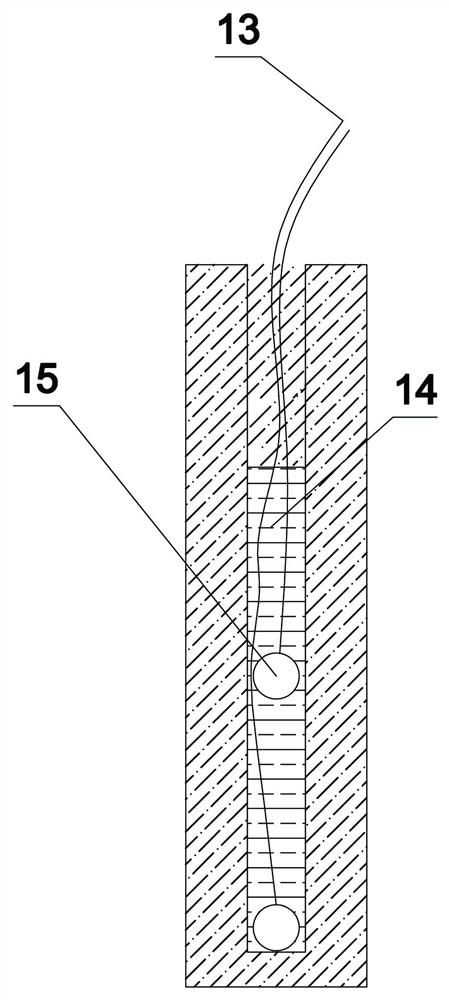

[0035] 1) According to the measured data, arrange blastholes 31 on the roof of the upper goaf, blastholes 32 on the roof of the upper goaf in the overlapping area and penetration holes 2 in the upper goaf in the overlapping area. The bottom of the blastholes is 3m away from the lower boundary of the upper roof. The hole spacing is 7 m, the row spacing is 5 m, and the hole diameter is 220 mm, of which the outermost blast holes are 1 m from the boundary of the overlapping area;

...

Embodiment 2

[0045] The rock mass in the double-layer goaf is mainly composed of magnetite quartzite with a rock density of 3300-3400 kg / m 3 , the Platts firmness factor is 12-16, the length of the upper gob is 90 m, the width is 50 m, the thickness of the roof is 11-20 m, the length of the lower roof is 80 m, the width is 80 m, and the thickness of the lower roof is 13-18 m. The height between the upper roof and the lower roof is 30 m.

[0046] Concrete process implementation steps are as follows:

[0047] 1) According to the measured data, arrange blastholes 31 on the roof of the upper goaf, blastholes 32 on the roof of the upper goaf in the overlapping area and penetration holes 2 in the upper goaf in the overlapping area. The bottom of the blastholes is 3m away from the lower boundary of the upper roof. The hole spacing is 6 m, the row spacing is 4 m, and the hole diameter is 220 mm, of which the outermost blast hole is 1 m from the border of the overlapping area;

[0048] 2) Accordi...

Embodiment 3

[0057] The rock mass in the double-layer goaf is mainly composed of granite with a rock density of 2700-3000 kg / m 3 , the Platts firmness coefficient is 10, the length of the upper roof in the upper goaf is 90 m, the width is 50 m, the thickness of the roof is 14-18 m, the length of the lower roof is 100 m, the width is 70 m, the thickness of the lower roof is 12-17 m, the upper roof and The height between the lower roof slabs is 40 m.

[0058] Concrete process implementation steps are as follows:

[0059] 1) According to the measured data, arrange blastholes 31 on the roof of the upper goaf, blastholes 32 on the roof of the upper goaf in the overlapping area and penetration holes 2 in the upper goaf in the overlapping area. The bottom of the blastholes is 3m away from the lower boundary of the upper roof. The hole spacing is 6 m, the row spacing is 4 m, and the hole diameter is 220 mm, of which the outermost blast hole is 1 m from the border of the overlapping area;

[0060...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com