Static breaking roof cutting and pressure releasing method for gob-side retained roadway

A technology of roof cutting, pressure relief and static crushing, which is applied in blasting, earth square drilling, ground mining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

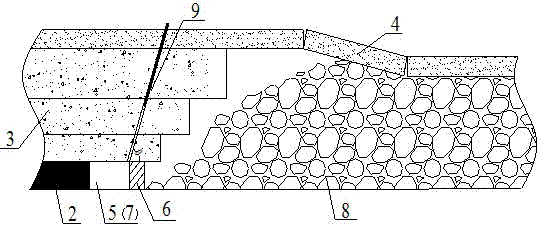

[0070] Taking the working face 1 of a certain mine as an example, see the attached figure 1 - attached Figure 4 As mentioned above, the mining face 1 is arranged along the 3# coal seam 2, the average thickness of the 3# coal seam 2 is 2.86m, the occurrence is stable, and the structure is relatively simple. Black sandy mudstone with an average thickness of 11.31m; the basic top 4 is fine sandstone with an average thickness of 2m. The mining face 1 adopts the "three inlets and one return" ventilation system, and pours a 2m-wide high-water quick-setting material filling wall 6 on the gob side 8 of the auxiliary air inlet lane 5 to retain it for transportation to the next working face. For level entry, the lateral roof cutting test of the goaf side 8 is carried out in the gob-side entry retention 7.

[0071] Step 1: According to the mine pressure observation data, during the mining process of mining face 1, the overlying strata was broken, resulting in significant deformation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com