Edible oil storage tank breather valve capable of automatically cleaning filter membrane

A technology for automatic cleaning and edible oil, applied in the direction of safety valve, balance valve, valve device, etc., can solve problems such as hidden safety hazards and easy blockage of filter membrane, so as to improve safety, reduce the possibility of blockage, clean complete effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

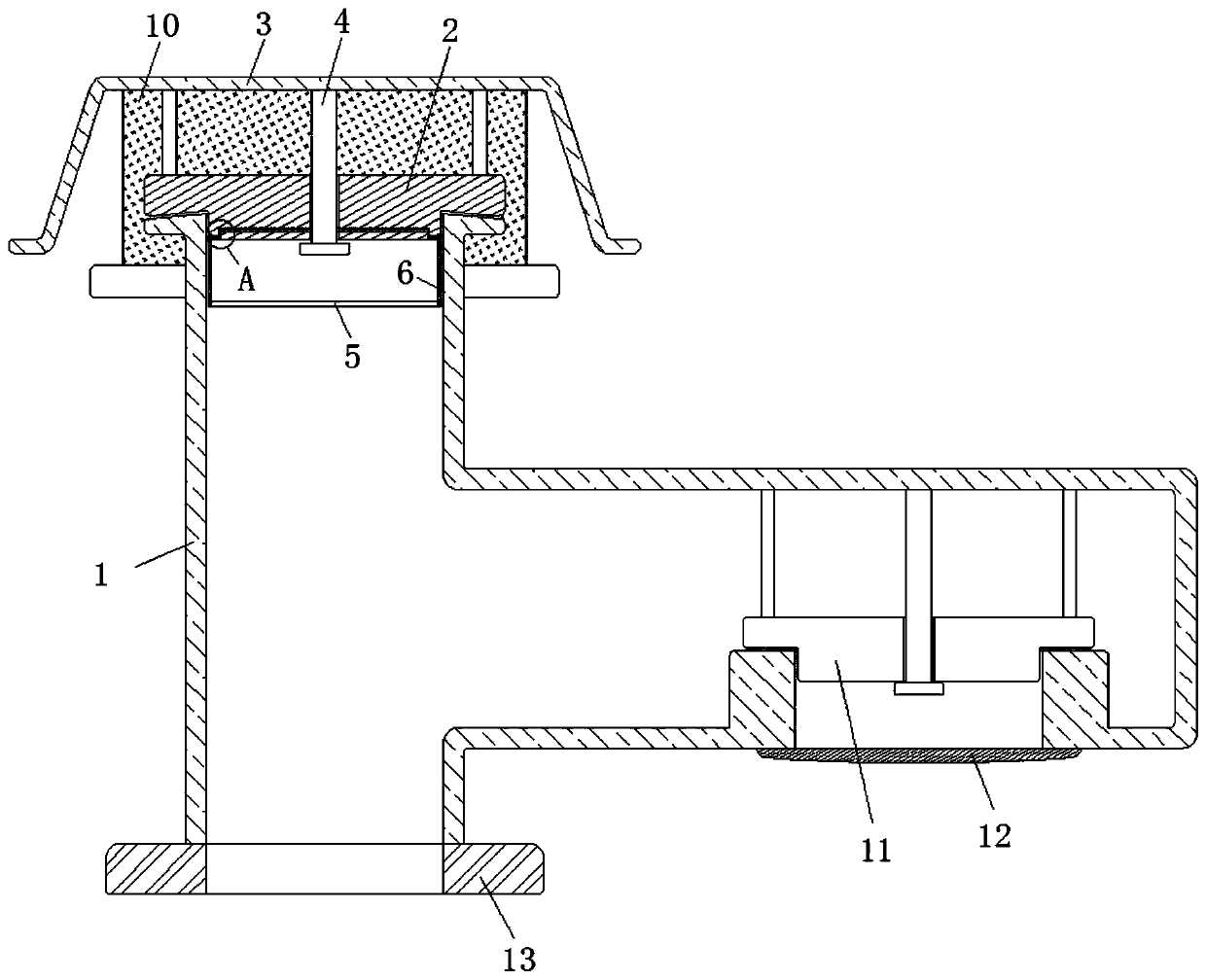

[0027] as attached figure 1 to attach Figure 6 Shown:

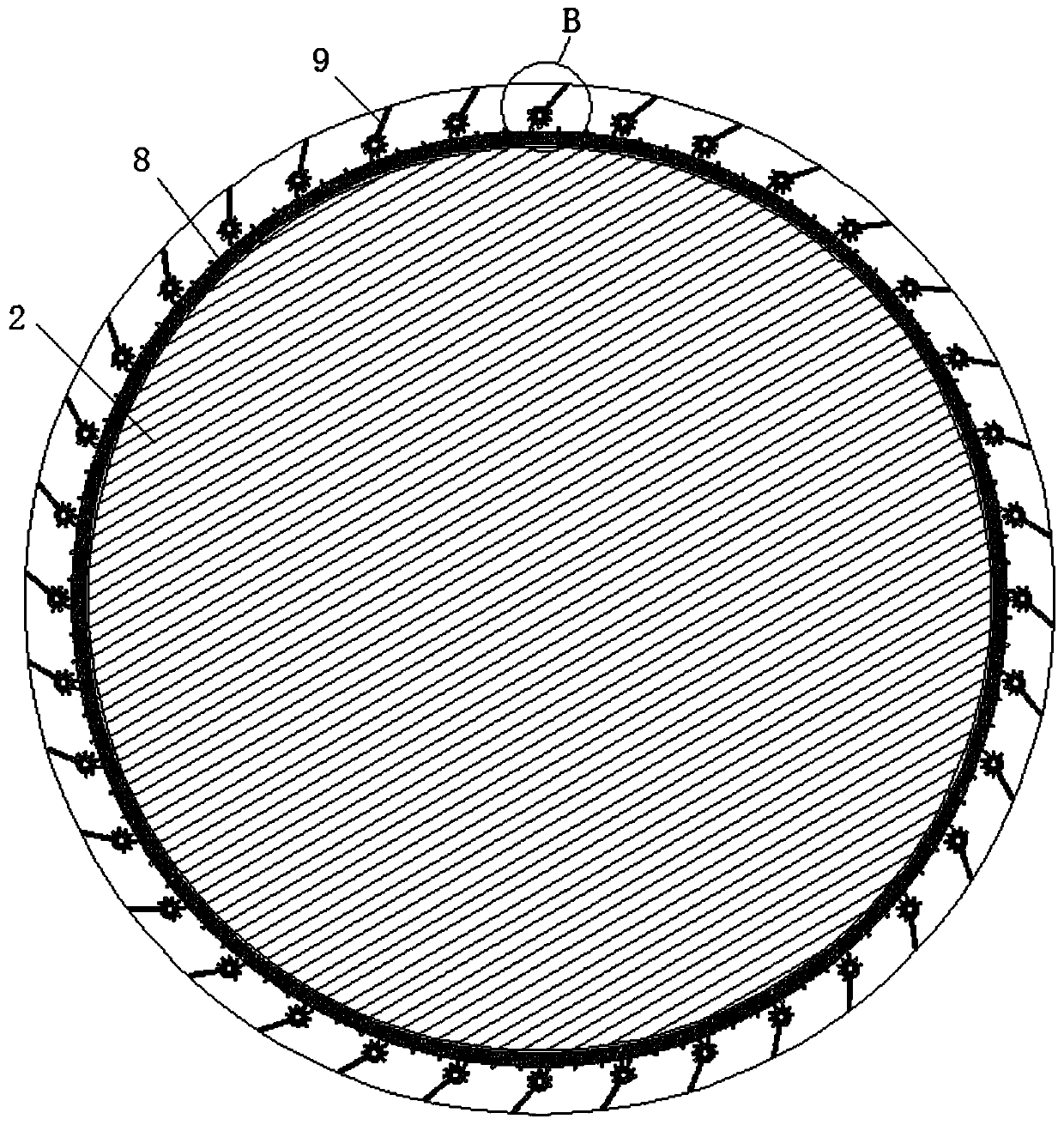

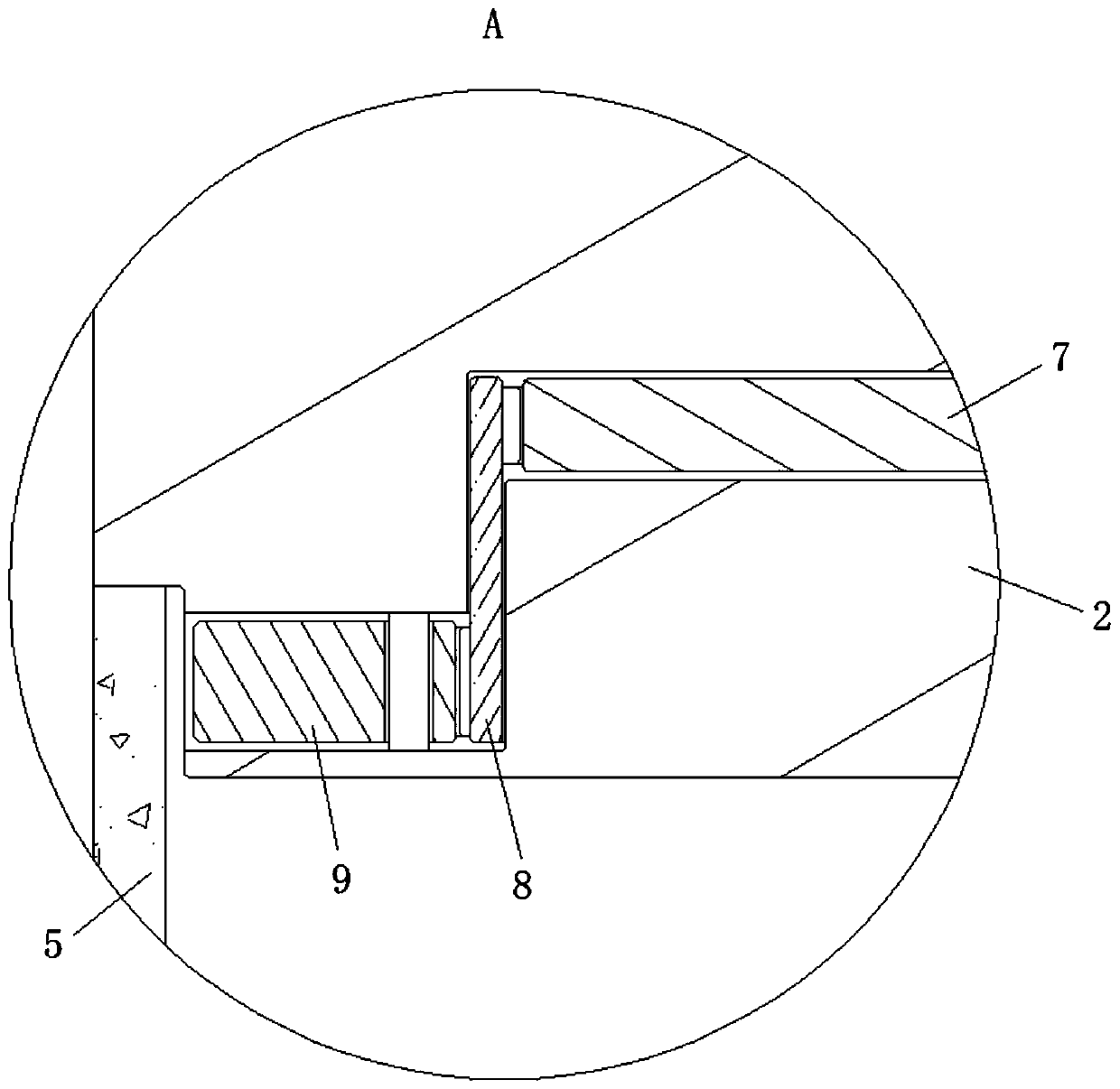

[0028] The invention provides an edible oil storage tank breathing valve capable of automatically cleaning the filter membrane, comprising a valve body 1, the top of the valve body 1 is movably installed with an exhalation valve disc 2, and the top of the valve body 1 is fixed above the exhalation valve disc 2 A rain cover 3 is installed, the bottom of the rain cover 3 is fixedly connected with a central rod 4 extending below the exhalation valve disc 2, the bottom of the exhalation valve disc 2 is fixedly connected with a support ring 5, and a filter membrane 6 is laid on the support ring 5 The inside of the exhalation valve disc 2 and the outer side of the central rod 4 are connected to the turntable 7, the inner part of the exhalation valve disc 2 and the outer side of the turntable 7 is rotatably connected to the rotary sleeve 8, and the inner part of the exhalation valve disc 2 is located on the rotary sleeve 8. E...

Embodiment 2

[0037] as attached Figure 7-8 Shown:

[0038] According to the actual situation, the connection structure of the scraper 9 can be changed. A group of scrapers 9 are installed in the valve body 1 through the rotating shaft 14. The rotating shaft 14 is evenly distributed on the outside of the rotating sleeve 8, and the scraper 9 is fixedly installed on the rotating shaft 14. , the connection relationship between the rotating shaft 14 and the valve body 1 is a rotational connection, the outer side of the rotating shaft 14 and above the scraper 9 is fixedly sleeved with a gear 15, the gear 15 is meshed with the rotating sleeve 8, and through the threaded section on the center column 4 Design with the number of one set of scrapers 9, so that the scrapers 9 are located inside the exhalation valve disc 2 at the initial state and at the end of rotation. Therefore, when the exhalation valve disc 2 moves down, the rotating sleeve 8 passes through the gear 15 The rotating shaft 14 driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com