Method for sinking ultra-long large-diameter permanent steel protective cylinder

A steel casing, large diameter technology, applied in construction, sheet pile wall, infrastructure engineering and other directions, can solve the problems of inaccessibility of large equipment, uneconomical large equipment, and small total amount of engineering, so as to improve safety and construction. Quality, improving quality and economy, improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0057] A method for sinking a super long-diameter permanent steel casing, comprising the following steps:

[0058] S1. Determine the length of the steel casing 1 section according to the actual construction situation, and transport the cut steel casing 1 section to the construction site for standby;

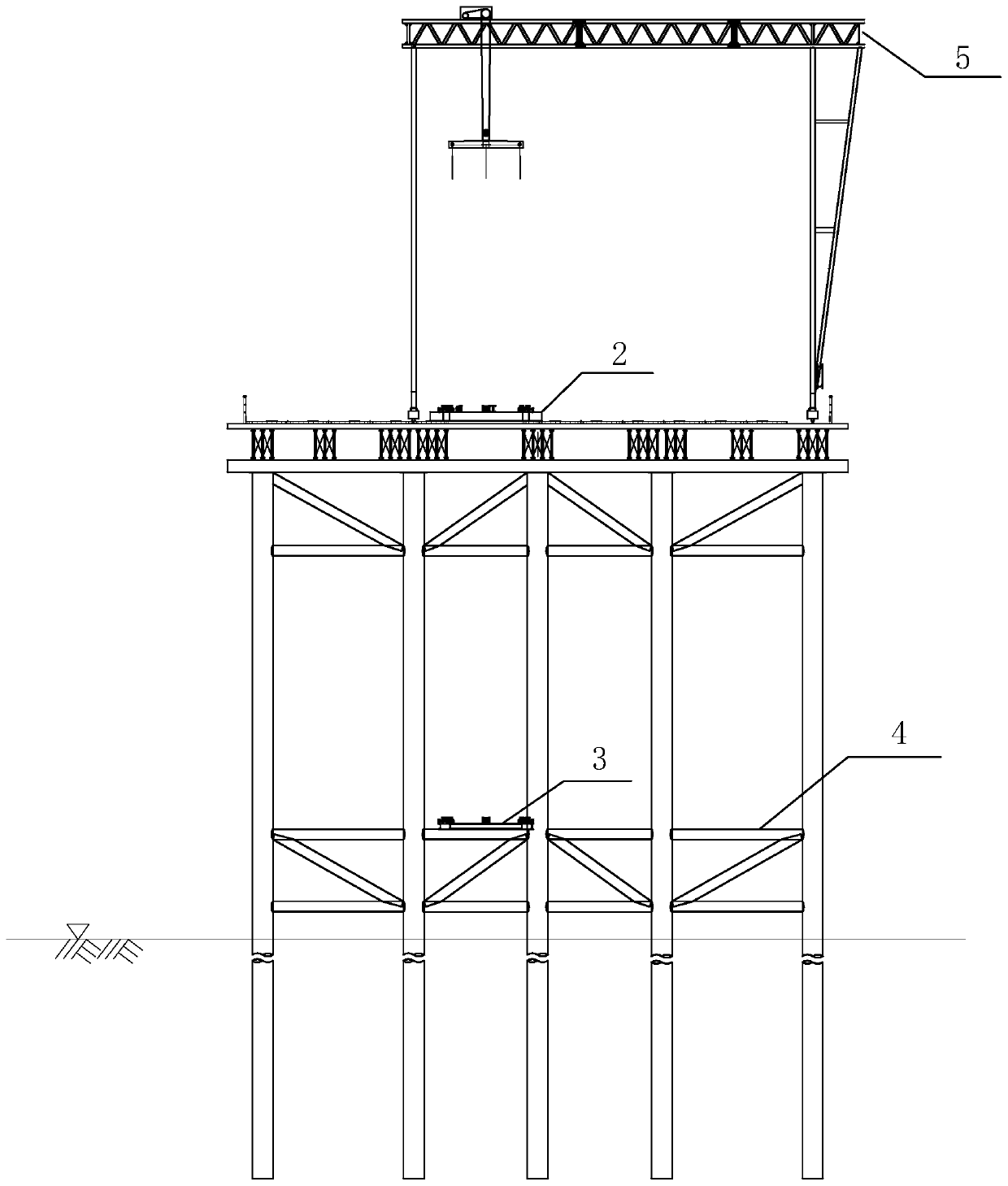

[0059] S2, such as figure 1 As shown, a double-layer section steel positioning guide frame is erected on the drilling platform, and the double-layer section steel positioning guide frame includes an upper layer guide frame 2 arranged on the top surface of the drilling platform, and a lower layer arranged on the horizontal connection 4 of the steel pipe pile of the drilling platform guide frame 3;

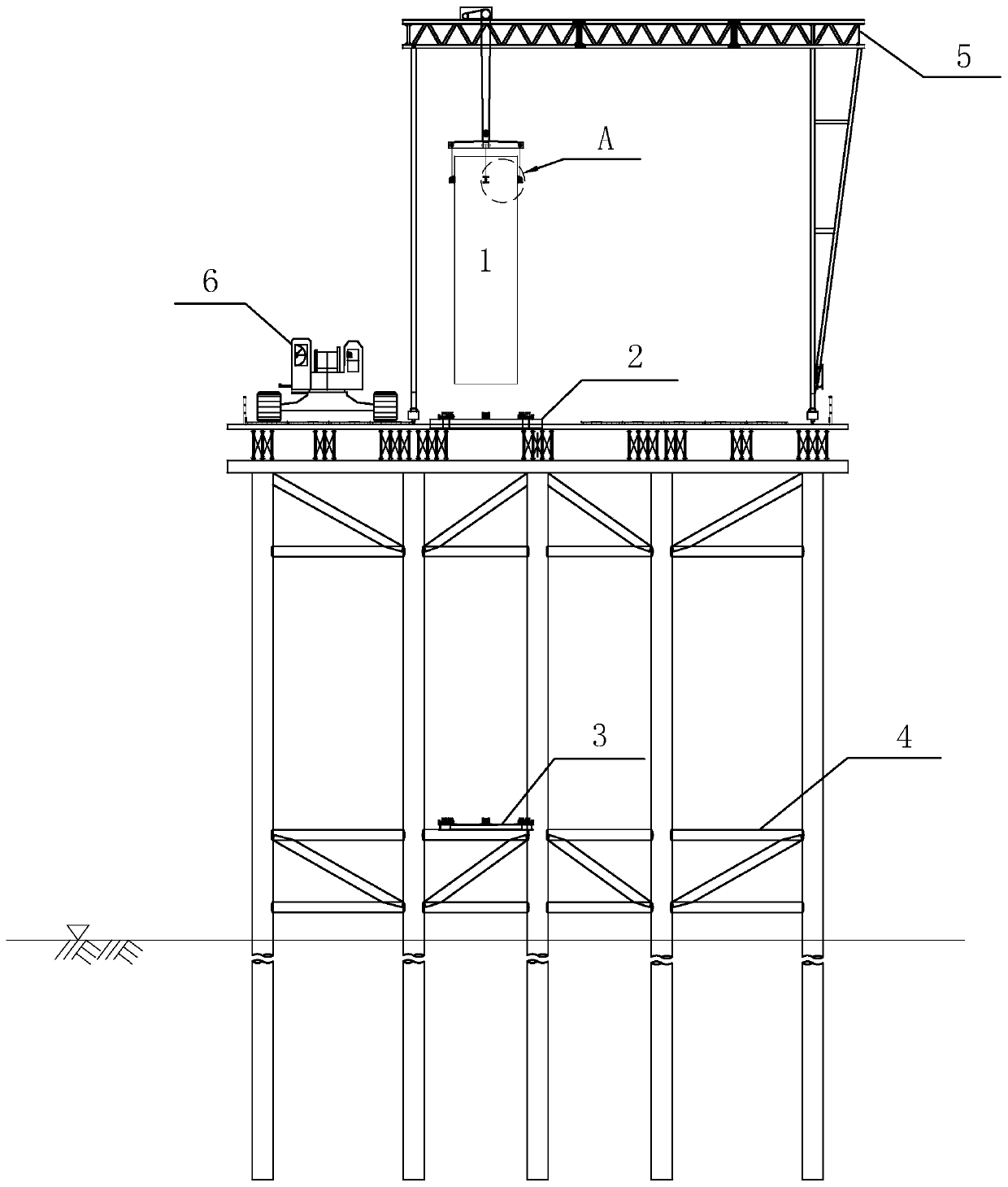

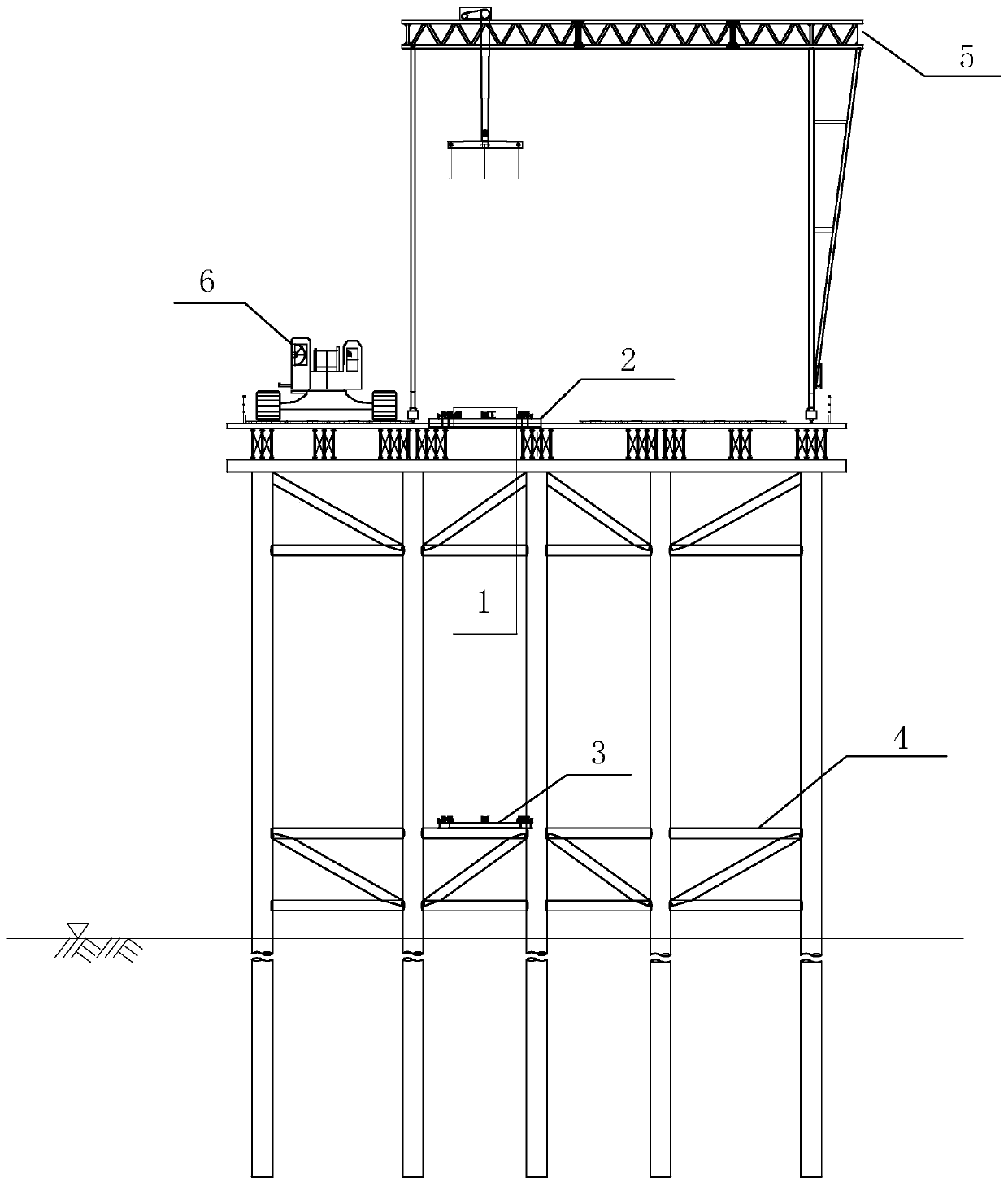

[0060] S3. With the cooperation of the crawler crane 6, use the gantry crane 5 to hoist the first section of the steel casing 1, such as figure 2 As shown, the first steel casing 1 passes through the upper guide frame 2 vertically, and is lowered to the lifting lug 10 on the top to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com