Method for preparing nitrogen-doped carbon nano array-ferronickel hydrotalcite oxygen evolution electrode

A nano-array, nitrogen-doped carbon technology, applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., can solve the problems of difficult preparation of nano-array structure, easy aggregation of hydrotalcite structure, and toxic and harmful substances in the preparation method, so as to be suitable for Promoted app performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

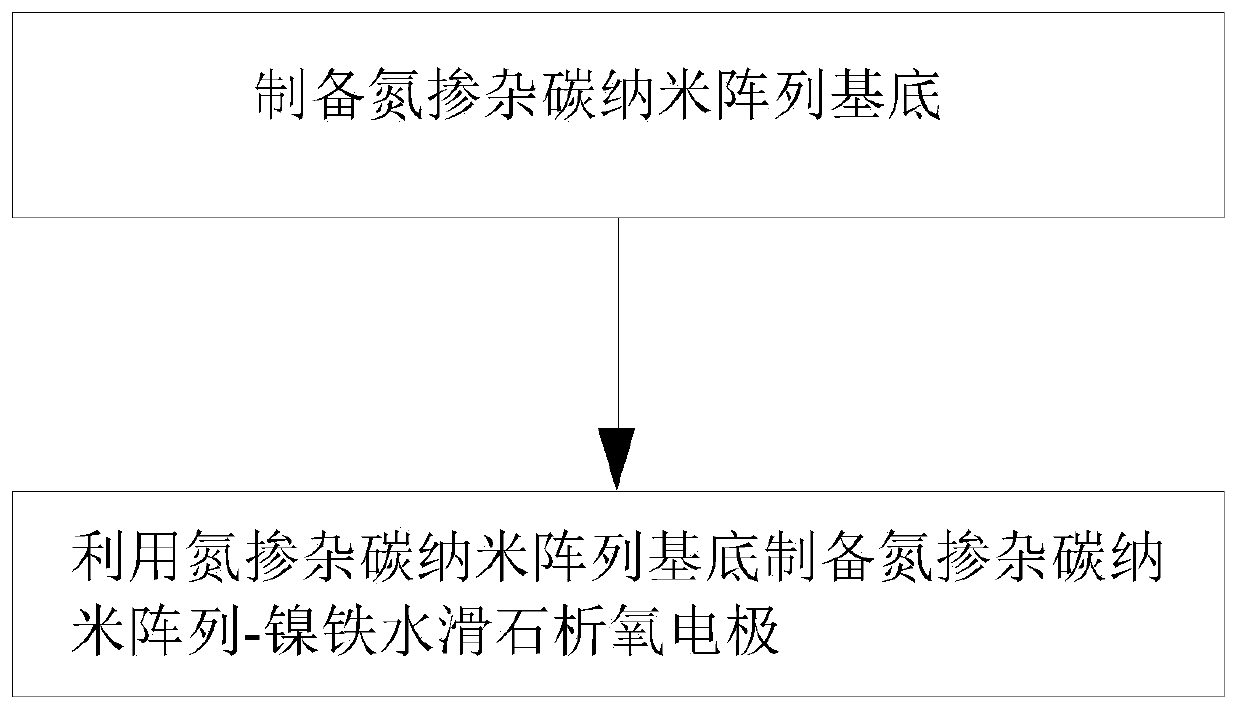

[0021] The invention provides a method for preparing nitrogen-doped carbon nano-array-nickel-iron hydrotalcite oxygen evolution electrode, which has the advantages of simple preparation method, convenient operation and no pollution. The main design idea of the invention is to realize the nitrogen doping of the graphite foil and the preparation of the surface nano-array structure in one step, and then select the electrodeposition method to obtain the nickel-iron hydrotalcite without affecting the shape of the nano-array. Its main process is as figure 1 As shown, including: 1. Preparation of nitrogen-doped carbon nano-array; 2. Preparation of nitrogen-doped carbon nano-array-nickel-iron hydrotalcite oxygen evolution electrode.

[0022] The two main processes are introduced in turn below.

[0023] 1. Preparation of nitrogen-doped carbon nanoarrays

[0024] In the present invention, the preparation of the nitrogen-doped carbon nanoarray structure is mainly realized by ion impl...

Embodiment 1

[0029] The graphite foil was placed in a beamline ion implantation device, and irradiated for 50 min with a Kaufmann gas ion source at 50 kV in a nitrogen atmosphere to obtain a nitrogen-doped carbon nanoarray. The obtained nitrogen-doped carbon nanoarray substrate was used as a working electrode, the platinum electrode was used as a counter electrode, and the silver / silver chloride electrode was used as a working electrode. Constant potential deposition was carried out in a mixed solution composed of 40mM nickel sulfate and 5mM iron sulfate. The temperature is -1.2V, the deposition time is 60s, and the residual salts are removed by washing to obtain a nitrogen-doped carbon nanoarray-nickel-iron hydrotalcite oxygen evolution electrode. .

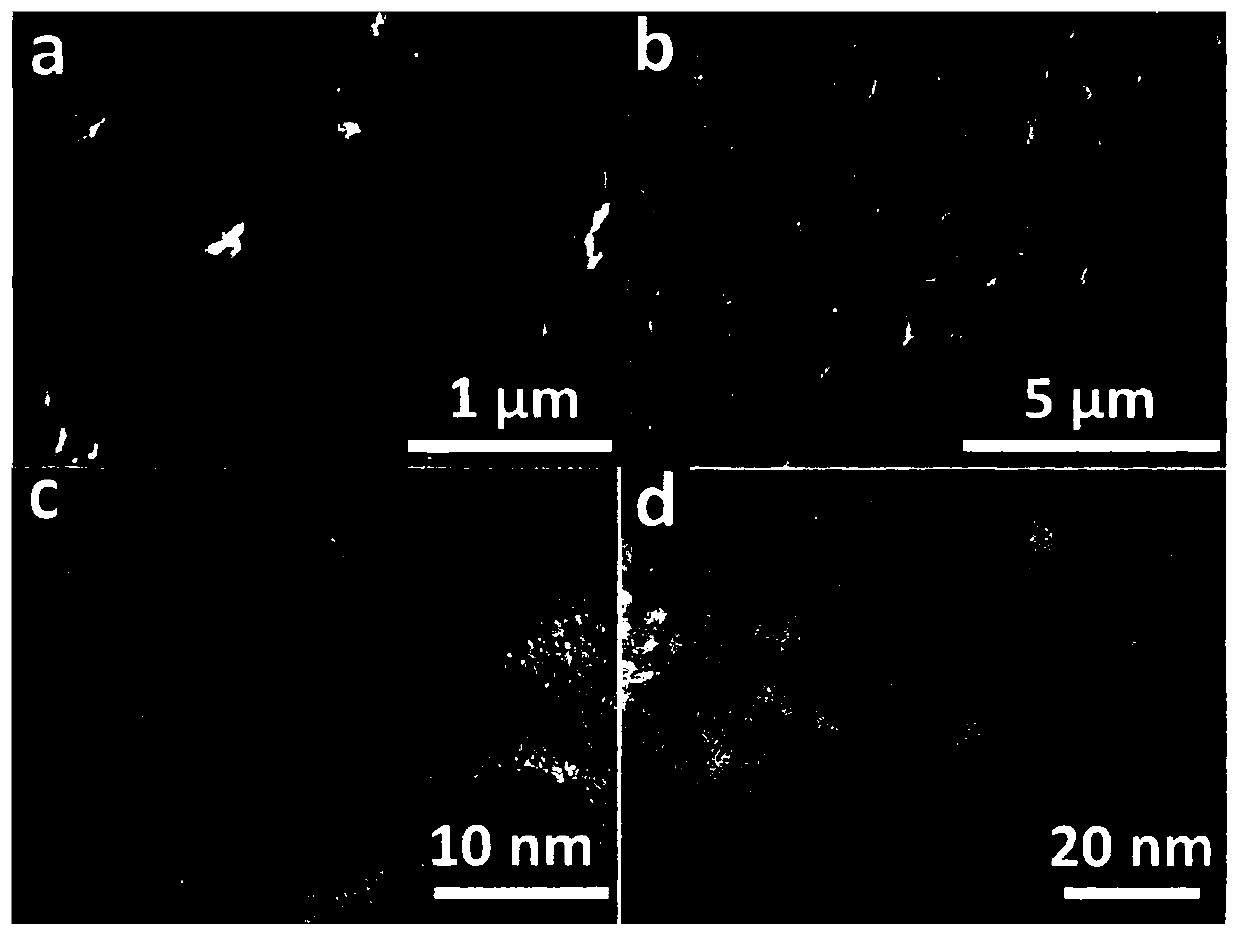

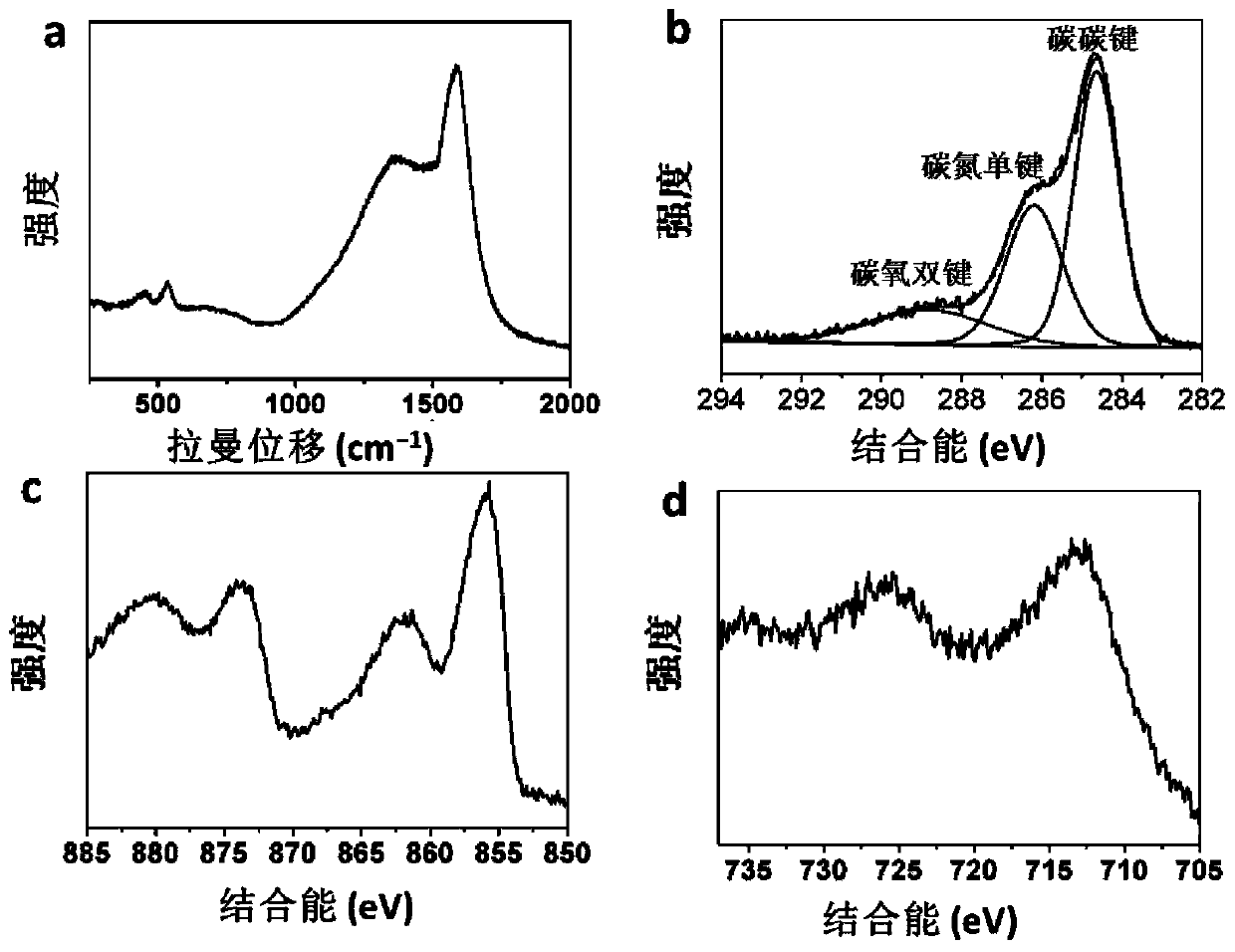

[0030] Depend on figure 2 In (a, b), it can be seen that the surface of the nitrogen-doped carbon nanoarray-nickel-iron hydrotalcite oxygen evolution electrode prepared by the present invention is a uniformly distributed nanoarray. Depend...

Embodiment 2

[0032] The graphite foil was placed in a beamline ion implantation device, and irradiated with a Kaufmann gas ion source at 30 kV for 60 min in a nitrogen atmosphere to obtain a nitrogen-doped carbon nanoarray. The obtained nitrogen-doped carbon nanoarray substrate was used as a working electrode, the platinum electrode was used as a counter electrode, and the silver / silver chloride electrode was used as a working electrode. Constant potential deposition was carried out in a mixed solution composed of 90mM nickel sulfate and 5mM iron sulfate. The temperature is -1.1V, the deposition time is 60s, and the residual salts are removed by washing to obtain a nitrogen-doped carbon nanoarray-nickel-iron hydrotalcite oxygen evolution electrode. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com