Seam-like welding-traveling wave-like magnetic field composite method for improving defects of cladding layer

A technology of traveling wave magnetic field and cladding layer, which is applied in the direction of coating, metal material coating process, etc., can solve the problems of short existence time of molten pool and does not take into account the cladding speed of laser cladding, and achieve fast cooling time, The effect of increasing the rise and escape time of the stomata and shortening the existence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

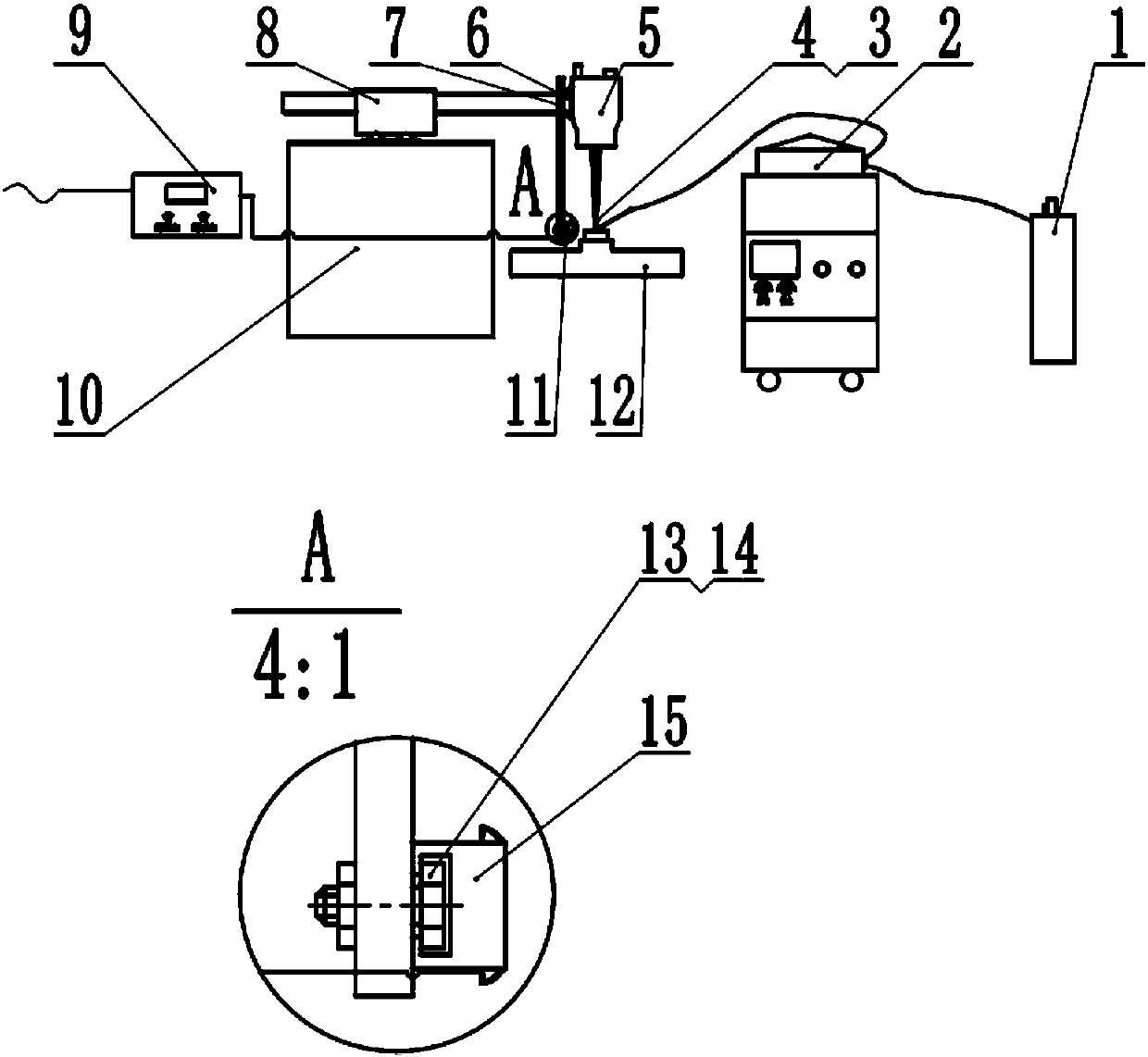

Embodiment 1

[0029] 1. The Q235 (chemical composition percentage Wt% is: 0.5Mn, 0.3Si, 0.2C, 0.05S, 0.045P, Fe balance) substrate plate with a size of 100mm*20mm*20mm (length*width*height) is covered Fix it on the workbench, and fine-tune the relative position of the electrode substrate and the numerical control device, so that the focus of the laser beam is located at the center of the rectangular through hole. Adjust the position of the connecting lug so that the distance between the two electrode rollers is d 1 25mm, adjust the position of the fastening nut on the electrode column, so that the electrode roller is pressed against the upper surface of the substrate;

[0030] 2. Turn on the main power switch of seam welding, adjust the current and series of the primary side, so that the current i through the workpiece 1 It is 5kA to realize the preheating treatment of the substrate workpiece, measure the temperature of the substrate with an infrared thermometer, and when the temperature r...

Embodiment 2

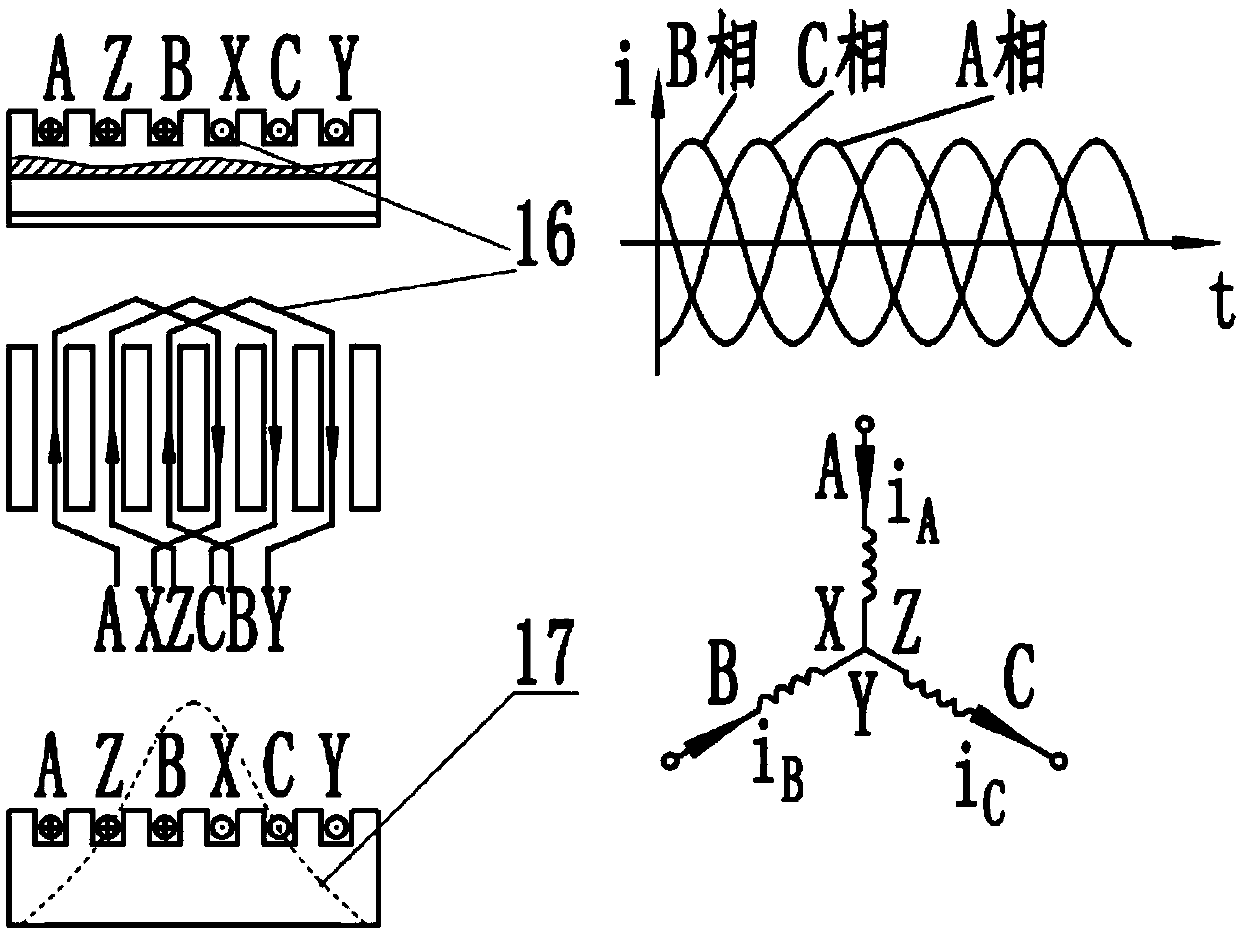

[0033] Method is all identical with embodiment 1, only the 2nd walking wave magnetic field power source control device of embodiment 1 makes each phase energization frequency be 80Hz, each phase energization current i A (or i B i C ) for 3A.

Embodiment 3

[0035] The methods are all the same as in Example 1, only the second step of Example 1 passes the workpiece current i 1 is 8kA, the traveling wave magnetic field power supply control device makes the frequency of each phase energized at 80Hz, and the energized current of each phase i A (or i B i C ) for 3A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com