High-thermal-resistant high-crosslinking degree photocuring solder resist ink and preparation method thereof

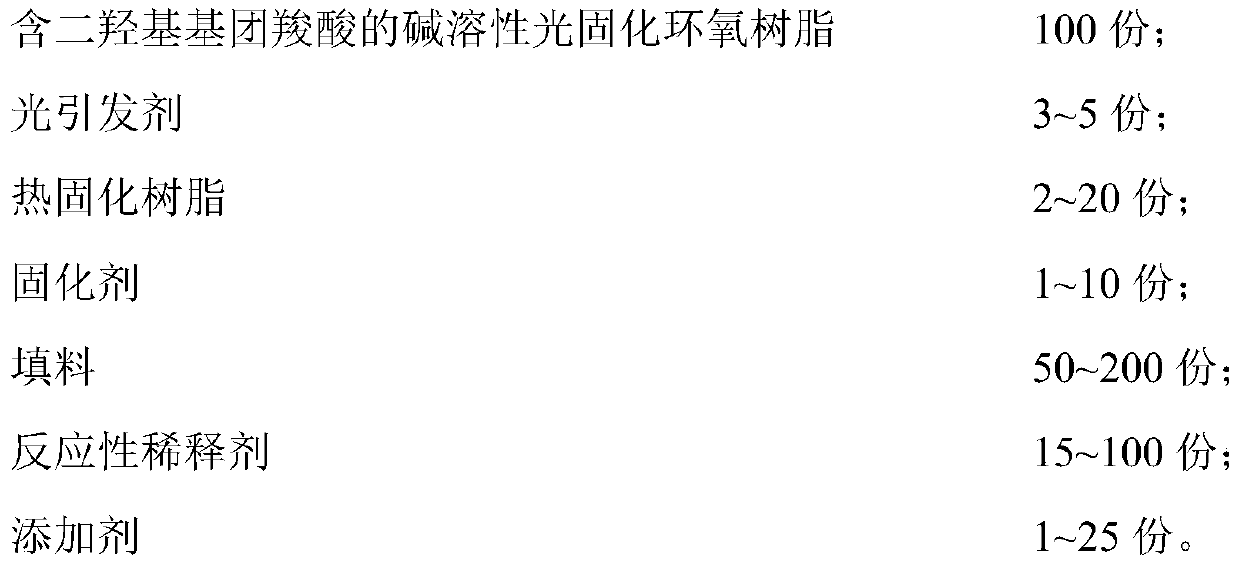

A technology of high cross-linking degree and solder resist ink, which is applied in the fields of high heat resistance and high cross-linking degree light-curing solder resist ink and its preparation, high cross-linking degree light-curing solder resist ink and its preparation field, which can solve the problem of system dispersion. Uniform, difficult to form a uniform film, difficult to separate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

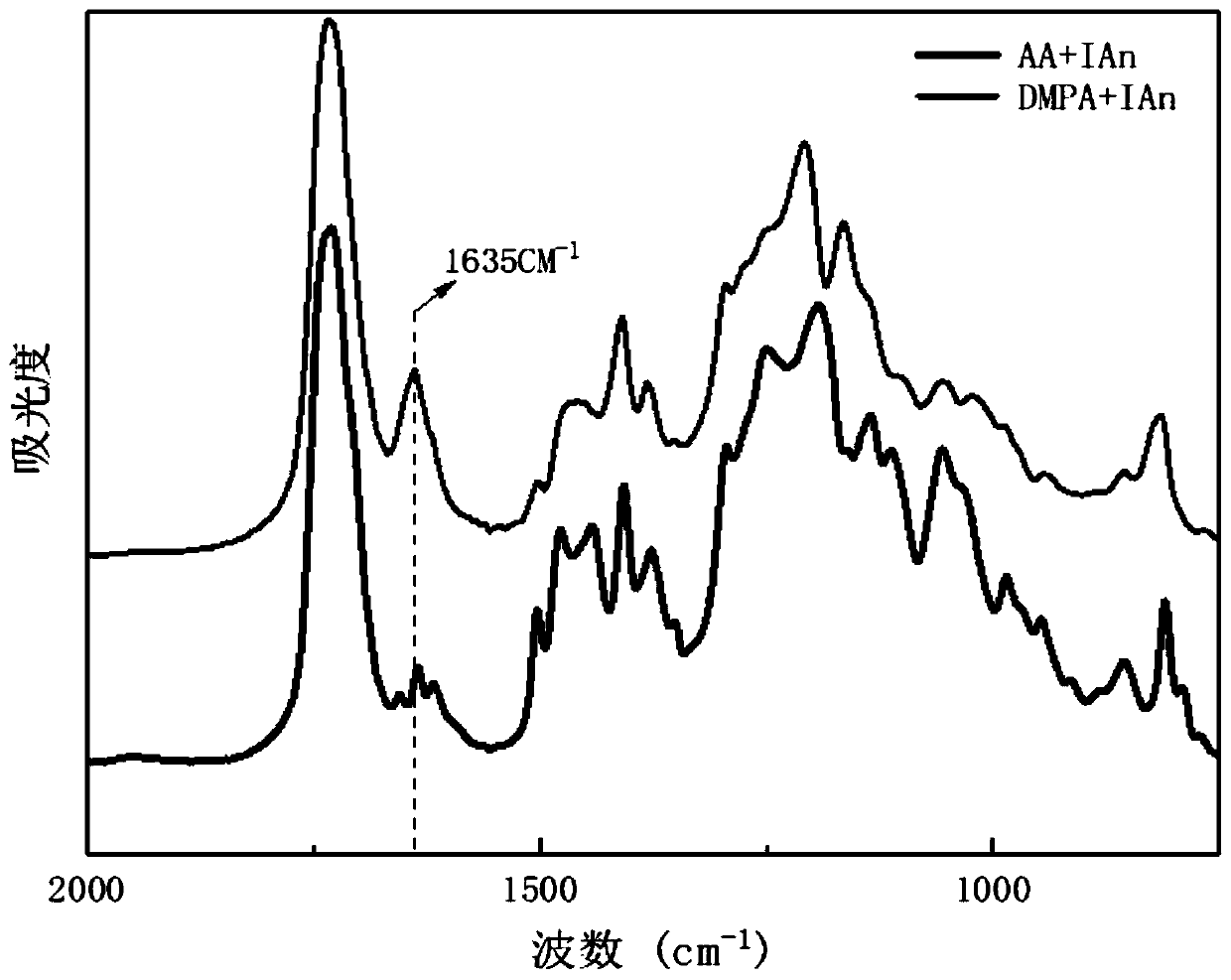

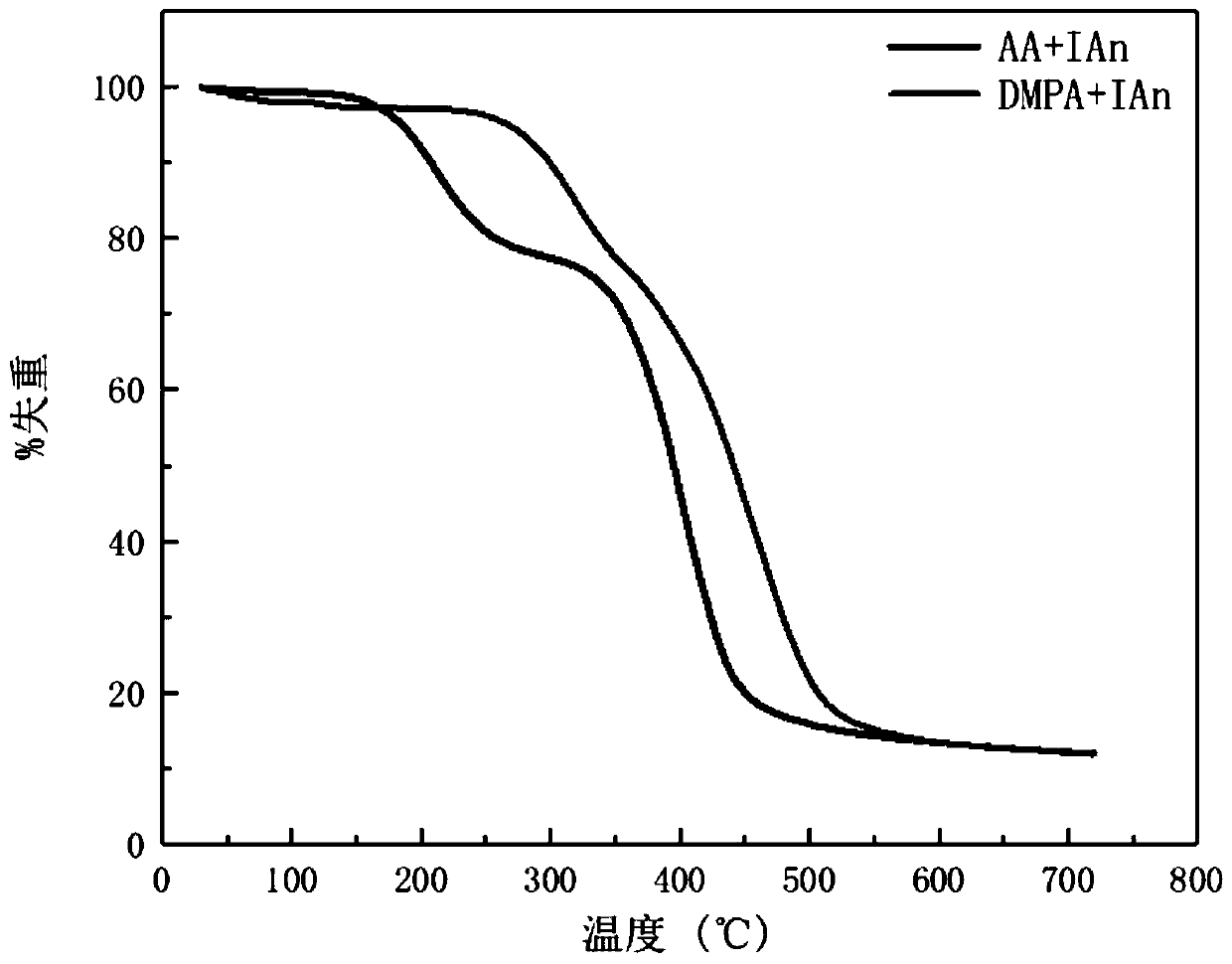

[0055] Under nitrogen protection, add 50.0g of diethylene glycol diethyl ether acetate (DCAC) into a 1L three-necked flask equipped with a stirrer, raise the temperature to 90°C, add 88.8g of epoxy resin NPCN-704, and keep the temperature for one hour to fully Dissolve, cool down to 60°C and add 57.3g of 2,2-dimethylolpropionic acid (DMPA) dissolved in 40g of diethylene glycol ether acetate (DCAC) (the molar ratio of epoxy group to carboxyl group is 1: 1), heat up to 70°C and then add 1.5g of catalyst 4-dimethylaminopyridine dissolved in 2g of diethylene glycol ethyl ether acetate, stir and react at a constant temperature of 95°C for 1 hour, then heat up to 105°C and stir at a constant temperature React for 12 hours. Then cool the reaction system to 80°C, add 94.0 g of itaconic anhydride dissolved in 30 g of diethylene glycol ethyl ether acetate (the molar ratio of carboxylic acid to anhydride is 1:2.1) and 0.5 g of hydroquinone as a polymerization inhibitor , the temperature...

Synthetic example 2

[0057] Under nitrogen protection, add 50.0g of diethylene glycol diethyl ether acetate (DCAC) into a 1L three-necked flask equipped with a stirrer, raise the temperature to 90°C, add 88.8g of epoxy resin NPCN-704, and keep the temperature for one hour to fully Dissolve, cool down to 60°C and add 57.3g of 2,2-dimethylolpropionic acid (DMPA) dissolved in 40g of diethylene glycol ether acetate (DCAC) (the molar ratio of epoxy group to carboxyl group is 1: 1), heat up to 70°C and then add 1.5g of catalyst 4-dimethylaminopyridine dissolved in 2g of diethylene glycol ethyl ether acetate, stir and react at a constant temperature of 95°C for 1 hour, then heat up to 105°C and stir at a constant temperature React for 12 hours. Then the reaction system was cooled to 80°C, and 82.2 g of maleic anhydride (MAH) dissolved in 30 g of diethylene glycol ether acetate (the molar ratio of carboxylic acid to anhydride was 1:2.1) and a pair of polymerization inhibitors were added. 0.5 g of hydroqu...

Synthetic example 3

[0059] Under nitrogen protection, add 50.0g of diethylene glycol diethyl ether acetate (DCAC) into a 1L three-necked flask equipped with a stirrer, raise the temperature to 90°C, add 88.8g of epoxy resin NPCN-704, and keep the temperature for one hour to fully Dissolve, cool down to 60°C and add 63.3g of 2,2-dimethylolbutyric acid (DMBA) dissolved in 40g of diethylene glycol ether acetate (DCAC) (the molar ratio of epoxy group to carboxyl group is 1: 1), heat up to 70°C and then add 1.5g of catalyst 4-dimethylaminopyridine dissolved in 2g of diethylene glycol ethyl ether acetate, stir and react at a constant temperature of 95°C for 1 hour, then heat up to 105°C and stir at a constant temperature React for 12 hours. Then cool the reaction system to 80°C, add 94.0 g of itaconic anhydride dissolved in 30 g of diethylene glycol ethyl ether acetate (the molar ratio of carboxylic acid to anhydride is 1:2.1) and 0.5 g of hydroquinone as a polymerization inhibitor , the temperature w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com