High-strength impervious concrete and preparation method thereof

A high-strength impermeable concrete technology, applied in the field of building materials, can solve the problems of reduced mechanical properties such as concrete strength, reduced concrete toughness, poor hydration-limited strength, etc., to achieve excellent mechanical properties, improve compressive strength, and air-entrained capacity small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

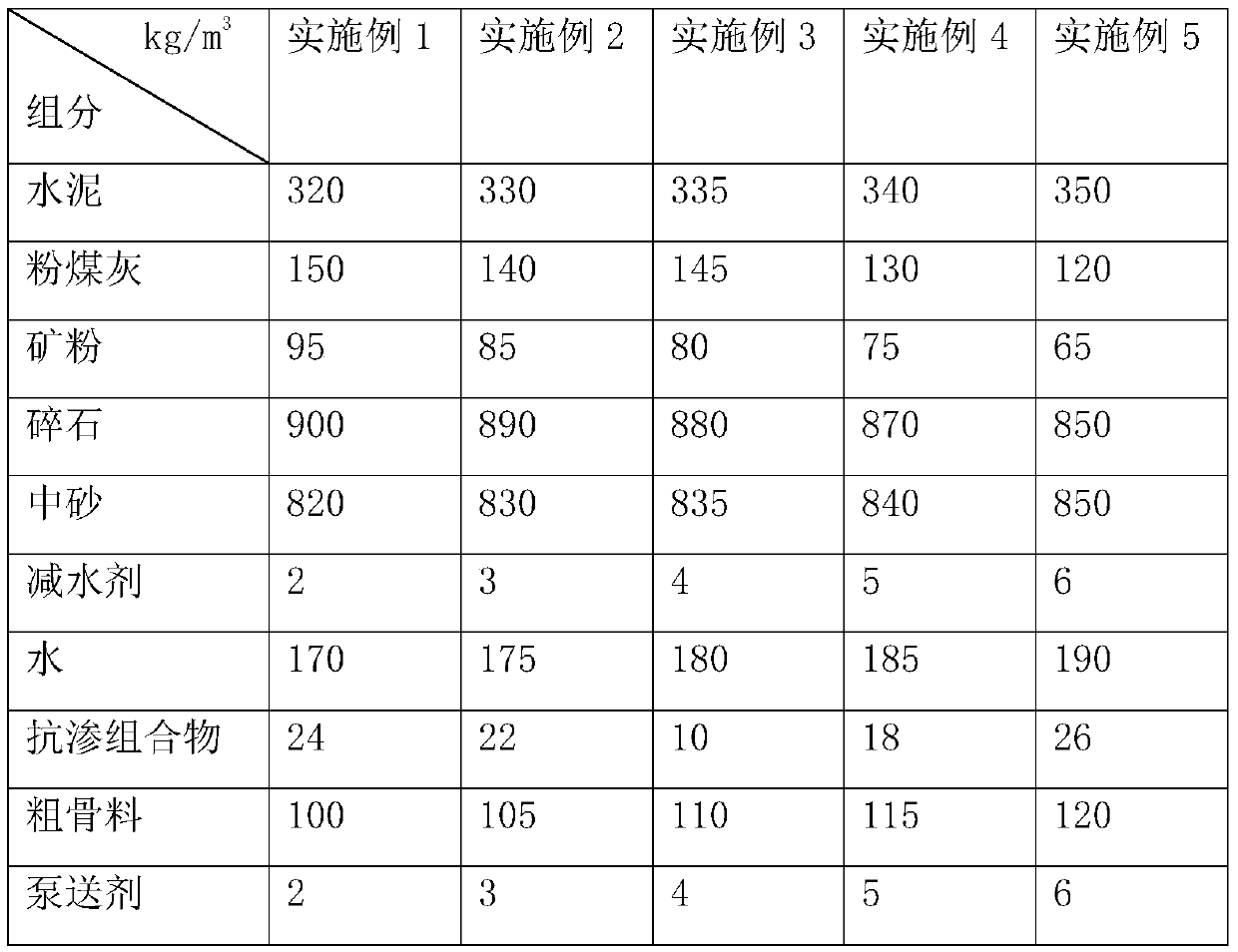

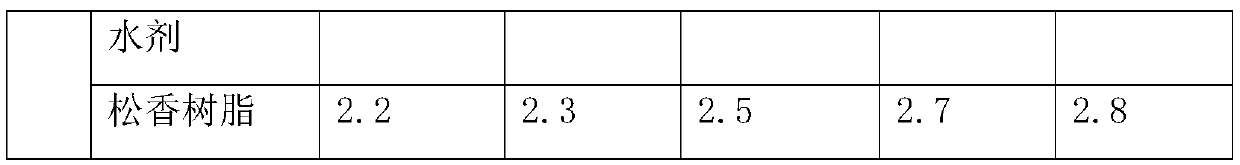

Examples

preparation example 1-3

[0043] In the preparation examples 1-3, the rubber particles were selected from the rubber particles sold by Changzhou Rongao Chemical New Material Co., Ltd. with the article number RA-XJF, and the water-soluble epoxy resin was selected from the model SR- sold by Guangdong Shengtu New Material Technology Co., Ltd. 670 water-based epoxy resin.

preparation example 1

[0044] Preparation Example 1: (1) Put rubber particles in 10% sodium hydroxide, soak for 25 hours, filter, wash, and dry;

[0045] (2) placing the rubber particles in an acidic potassium permanganate solution with a nitric acid content of 1.5% and a concentration of 1.5%, soaking for 24 hours, filtering, cleaning, and drying;

[0046] (3) Water-soluble epoxy resin and water are mixed uniformly according to the mass ratio of 1:3, add the rubber particle that step (1) and step (2) make, solidify at room temperature, be pulverized into the particle that average particle diameter is 10um, The mass ratio of the water-soluble epoxy resin, the rubber particles in step (1) and the rubber particles in step (2) is 1:1.2:0.8.

preparation example 2

[0047] Preparation Example 2: (1) Put rubber particles in 13% sodium hydroxide, soak for 23 hours, filter, wash, and dry;

[0048] (2) placing the rubber particles in an acidic potassium permanganate solution with a nitric acid content of 1.8% and a concentration of 1.3%, soaking for 22 hours, filtering, cleaning, and drying;

[0049] (3) Water-soluble epoxy resin and water are mixed evenly according to the mass ratio of 1:4, add the rubber particle that step (1) and step (2) make, solidify at room temperature, be pulverized into the particle that average particle diameter is 20um, The mass ratio of the water-soluble epoxy resin, the rubber particles in step (1) and the rubber particles in step (2) is 1:1.3:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com