Preparation method of magnetic polymer microsphere

A technology of polymer microspheres and seeds, which is applied to the preparation of microspheres, the magnetism of organic materials/organic magnetic materials, microcapsule preparations, etc., and can solve the problems of long reaction cycle, low production efficiency, and small particle impurities of magnetic polymer microspheres. and other problems, to achieve the effect of improving the uniformity of particle size, increasing the yield, and shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The embodiment of the present invention provides a preparation method of magnetic polymer microspheres, the preparation method comprising:

[0028] Add the polymer seeds into the aqueous solution containing the stabilizer and the initiator, and stir evenly to form a uniformly dispersed seed suspension;

[0029] Mix ferric oleate and monomer evenly to form ferric oleate monomer solution;

[0030] Forming uniform droplets of the iron oleate monomer solution through a nozzle into the seed suspension, the seeds absorb the droplets and grow and polymerize in one step to obtain iron oleate polymer microspheres;

[0031] Raise the temperature to decompose the iron oleate to obtain magnetic polymer microspheres.

[0032] Ferric oleate can be used and produced on the spot, and the specific preparation method of ferric oleate is well known to those skilled in the art. Preferably, ferric oleate can be prepared by the following method: soluble Fe 3+ Add salt and sodium oleate in...

Embodiment 1

[0048] Preparation of ferric oleate: Add soluble ferric chloride and sodium oleate into a mixture of 75% ethanol solution and n-hexane, heat and stir, filter, and vacuum dry to obtain ferric oleate.

[0049] Put 2g polyvinylpyrrolidone and 0.5g benzoyl peroxide in the first container that 600g deionized water is housed, stir evenly, add 56g polystyrene seed (its particle size is 0.8 micron, CV=3%), stir Homogenize to form a uniformly dispersed seed suspension and set aside.

[0050] Add 290g iron oleate and 206g ethyl acrylate into the second container, stir evenly to form iron oleate monomer solution, set aside. A nozzle with a hole diameter of 10 μm was installed on the second container. Apply a preset pressure of 2.15MPa to the second container, maintain a temperature environment of 97°C, disperse the iron oleate monomer solution into the seed suspension within 10 minutes in the form of droplets through the nozzle, and react for 110 minutes after spraying to obtain oil Ac...

Embodiment 2

[0054] Put 3.5g polyvinylpyrrolidone and 2.5g benzoyl peroxide in the first container that 1200g deionized water is housed, stir well, add 132g polystyrene seed (its particle size is 100nm, CV=2.8%), stir Homogenize to form a uniformly dispersed seed suspension and set aside.

[0055] Add 392g iron oleate and 398g styrene monomer into the second container, stir evenly to form iron oleate monomer solution, set aside. A nozzle was installed on the second container, and the nozzle had a hole diameter of 30 μm. Apply a preset pressure of 2.15MPa to the second container, maintain a temperature environment of 90°C, disperse the ferric oleate monomer solution into the seed suspension within 20 minutes in the form of droplets through the nozzle, and react for 100 minutes after spraying to obtain oil Iron acid polymer microspheres. Then raise the temperature to 290°C to decompose iron oleate to obtain magnetic polymer microspheres.

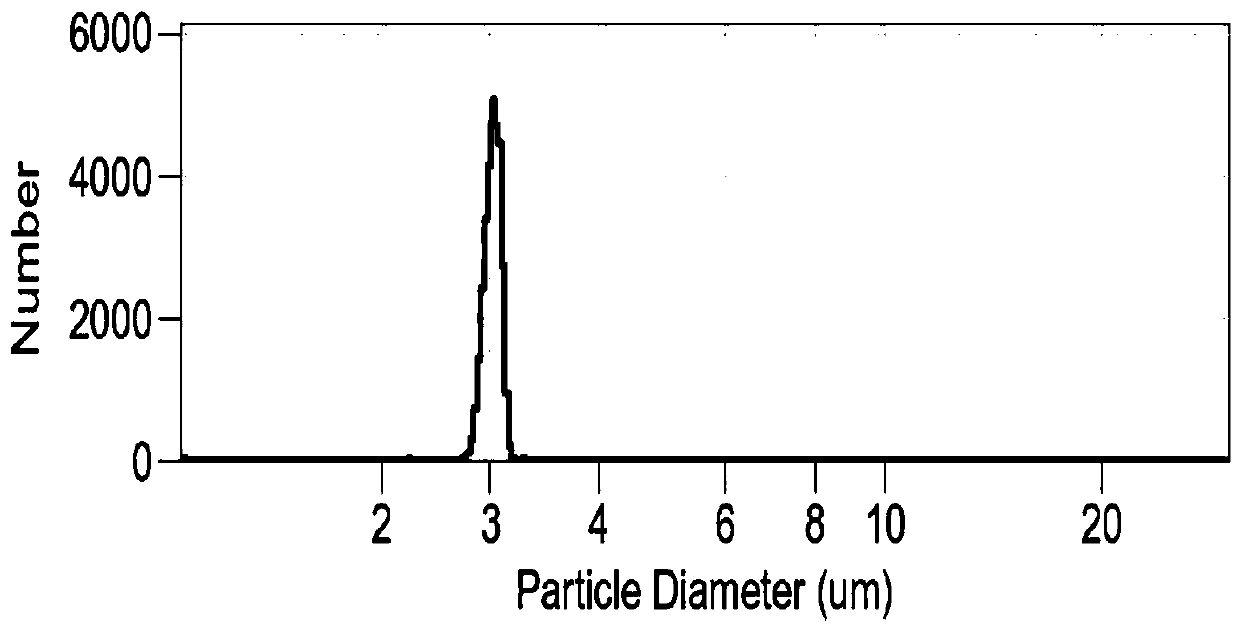

[0056] The particle size and particle size distri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com