Material increase and material decrease comprehensive manufacturing method of hard alloy part with complex shape

A technology of cemented carbide and complex shapes, which is applied in the direction of additive processing, metal processing equipment, transportation and packaging, etc. It can solve the problems of difficult forming and poor surface quality, and achieve low strength of the green body, easy machining, and elimination of The effect of the step effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

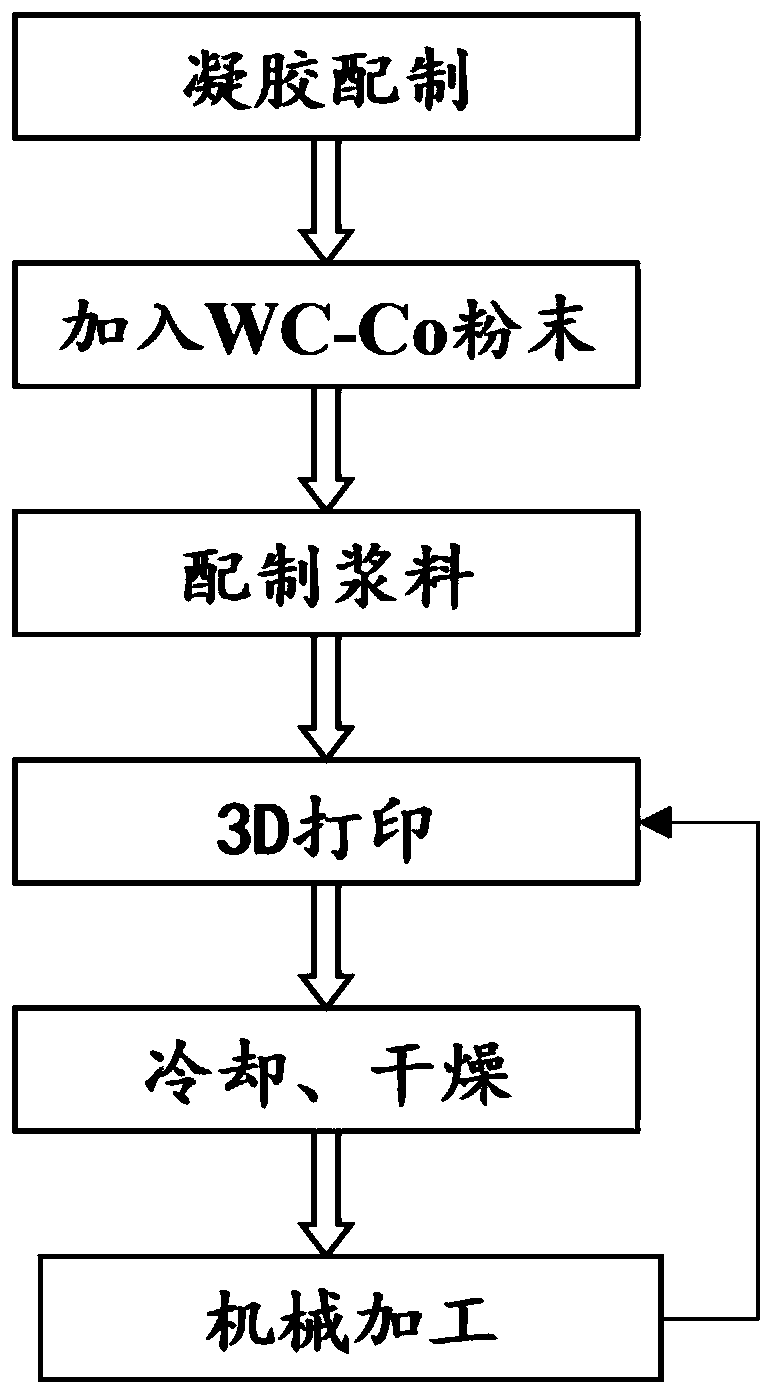

Method used

Image

Examples

Embodiment 1

[0035] Complicated shape WC-wt.8% Co cemented carbide parts:

[0036] 1) Preparation of gel system: Dissolve 9.3g of polystyrene-butadiene-styrene SBS (commercially available, model YH-792) in 90mL of toluene, and heat at 60°C to form a gel solution;

[0037] 2) Slurry preparation: Add 729 g of YG8 cemented carbide (commercially available, WC particle diameter 0.8 μm, Co particle diameter 0.5 μm, Co content wt.8%) powder in the above 1) gel solution, and use magnetic The agitator is stirred into a slurry, and the viscosity of the slurry is 350±20mPa·s;

[0038] 3) 3D printing NC programming: According to the requirements of the part drawings, use the 3D modeling software to model the parts and import them into the 3D printing device.

[0039] 4) 3D printing: transport the slurry in 2) to a 3D printing device, and perform 3D printing according to the control program in 3), with an extrusion speed of 20mm / s.

[0040] 5) Milling: When the 3D printed parts in 4) are accumulated ...

Embodiment 2

[0043] Complicated Shape WC-wt.6%Co Cemented Carbide Parts

[0044] 1) Preparation of the gel system: 18.6 g of polystyrene-butadiene-styrene (SBS) was dissolved in 90 mL of toluene, and heated at a constant temperature of 60 ° C to form a gel solution;

[0045] 2) Slurry preparation: Add 729 g of YG6 cemented carbide (commercially available, WC particle diameter 0.8 μm, Co particle diameter 0.5 μm, Co content wt.6%) powder in the above 1) gel solution, and use magnetic force The agitator is stirred into a slurry, and the viscosity of the slurry is 400±20mPa·s;

[0046] 3) 3D printing NC programming: According to the requirements of the part drawings, use the 3D modeling software to model the parts and import them into the 3D printing device.

[0047] 4) 3D printing: transport the slurry in 2) to a 3D printing device, and perform 3D printing according to the control program in 3), with an extrusion speed of 20mm / s.

[0048] 5) Milling processing: When the 3D printed parts in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com