Preparation method of nano cutting element iron-based magnetic fine polishing powder

A nano-cutting and iron-based powder technology, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of low encapsulation force and unreasonable array, so as to improve enveloping force, solve the problem of unreasonable array, The effect of low setting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

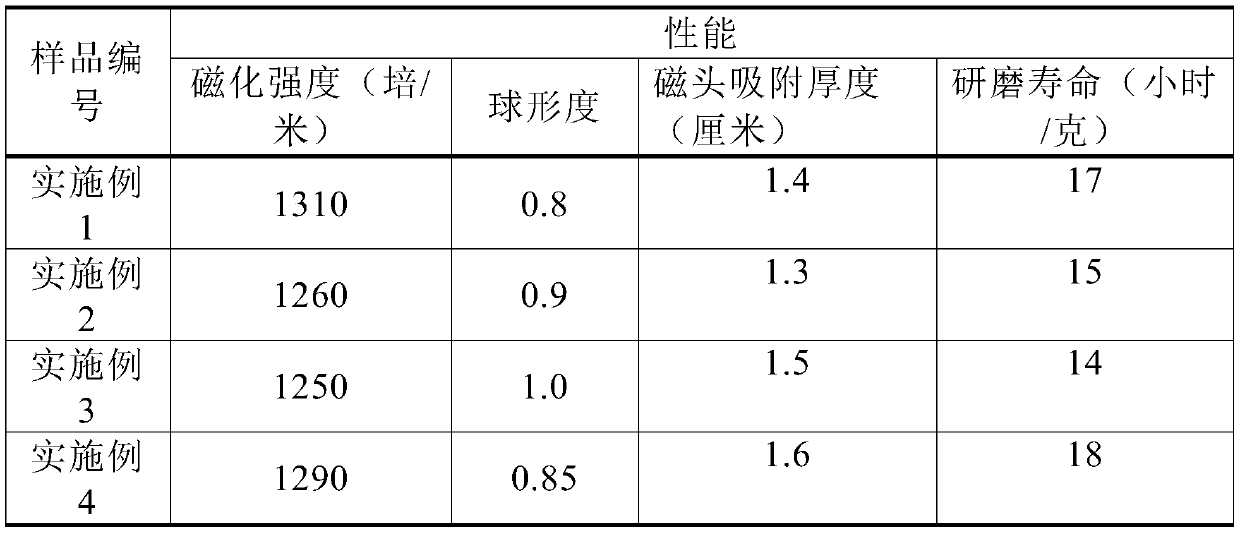

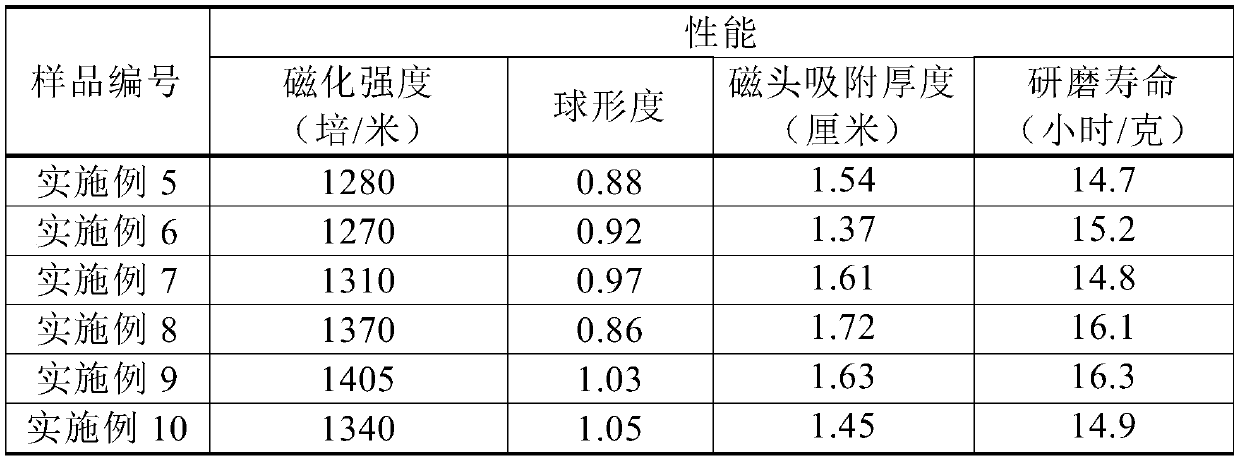

Examples

preparation example Construction

[0022] A kind of preparation method of nano-cutting element iron-based magnetic polishing powder of the present invention, comprises the following steps:

[0023] 1) Using cold air driven impact technology, the atomized iron powder with an average particle size of 130-210 microns will be impacted at a high speed on a honeycomb micro-involute mold with an effective inner diameter of 120-190 microns. The working temperature is 20-30 ° C, and the gas medium is air. The air velocity is 210-340 m / s, and at the same time, the mold is periodically vibrated at a frequency of 5-9 Hz to obtain double involute dent iron-based powder;

[0024] 2) Put the zirconia powder with an average particle size of 40-70 nanometers and the dispersant into the ammonium hydrogen phosphate solution at a mass ratio of 12-19:1, and then add double involute dent iron powder at a ratio of 50-110 g / L , the nano-powder is evenly arranged on the dent of the iron-based powder with a water-bath heat-collecting st...

Embodiment 1

[0027] 1) The atomized iron powder with an average particle size of 130 microns is used to impact the honeycomb micro-involute mold with an effective inner diameter of 120 microns at a high speed by using cold air-driven impact technology. The working temperature is 20°C, the gas medium is air, and the airflow speed is 210 m / s , while periodically vibrating the mold at a frequency of 5 Hz to obtain a double involute dent iron-based powder;

[0028] 2) Put the zirconia powder with an average particle size of 40 nanometers and the dispersant into the ammonium hydrogen phosphate solution at a mass ratio of 12:1, then add double involute dent iron powder at a ratio of 50 g / l, and stir in a water bath The device evenly arranges the nano-powder on the dent of the iron-based powder, the spindle speed of the stirring device is 450 rpm, the temperature of the water bath is 56°C, and then it is filtered with a silicon carbide fiber filter, washed with absolute ethanol, and dried at 55°C ...

Embodiment 2

[0032] 1) The atomized iron powder with an average particle size of 150 microns is used to impact the honeycomb micro-involute mold with an effective inner diameter of 140 microns at a high speed by using cold air-driven impact technology. The working temperature is 22°C, the gas medium is air, and the airflow speed is 230 m / s , while periodically vibrating the mold at a frequency of 6 Hz to obtain a double involute dent iron-based powder;

[0033] 2) Put the zirconia powder with an average particle size of 50 nanometers and the dispersant into the ammonium hydrogen phosphate solution at a mass ratio of 13:1, then add double involute dent iron powder at a ratio of 60 g / l, and stir in a water bath The device evenly arranges the nano-powders on the dents of the iron-based powders, the spindle speed of the stirring device is 470 rpm, the temperature of the water bath is 58°C, and then it is filtered with a silicon carbide fiber filter, washed with absolute ethanol, and dried at 55...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com