Biological composite air-permeable dressing and preparation method thereof

A biological and natural polymer technology, applied in the field of biocomposite breathable dressings and its preparation, can solve the problems of unable to keep the wound wet, unable to absorb tissue fluid, and affect wound healing, achieve stable drug loading and drug release, and eliminate pain Stimulation and secondary trauma and secondary infection, good bioremediation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The present invention also provides a preparation method of a biocomposite breathable dressing, the method comprising the following steps: step 1: mixing and stirring the natural polymer polysaccharide and a humectant until uniformly dispersed; step 2: mixing the cross-linking agent, the acid-base regulator , anti-oxidant, and drug-loaded functional ingredients are dissolved in water and added to the evenly dispersed mixture of natural high-molecular polysaccharides and humectants, and the natural high-molecular polysaccharides are fully stirred; step 3: prepare in step 2 Heat the preparation to any temperature between 75°C and 85°C to fully dissolve, then keep the dissolution temperature at a constant temperature for 30 minutes, and let it stand for natural cooling until the temperature drops to 50°C and store at a constant temperature; step 4: store at a constant temperature of 50°C in step 3 The formulation is coated or cast into a film, dehydrated and dried into a dr...

Embodiment 1

[0070]

[0071] Step 1: Mix carrageenan, guar gum and glycerin and stir until evenly dispersed;

[0072] Step 2: Dissolve calcium chloride, sodium chloride, citric acid, polylysine, phenoxyethanol, and silk fibroin in water and add them to the evenly dispersed mixture of carrageenan, guar gum, and glycerin. And make the carrageenan and guar gum fully stirred;

[0073] Step 3: Heat the preparation prepared in step 2 to 75°C and fully dissolve it, then keep the dissolution temperature at a constant temperature for 30 minutes, let it stand for natural cooling, and store it at a constant temperature when the temperature drops to 50°C;

[0074] Step 4: Coat or cast the formulation stored at a constant temperature of 50°C in step 3 to form a film, and use microwave or infrared dehydration drying equipment to dehydrate and dry at 40°C to form a dry film, then cover with a protective film, wind into a film, and cut into shape , Packaging and sealing.

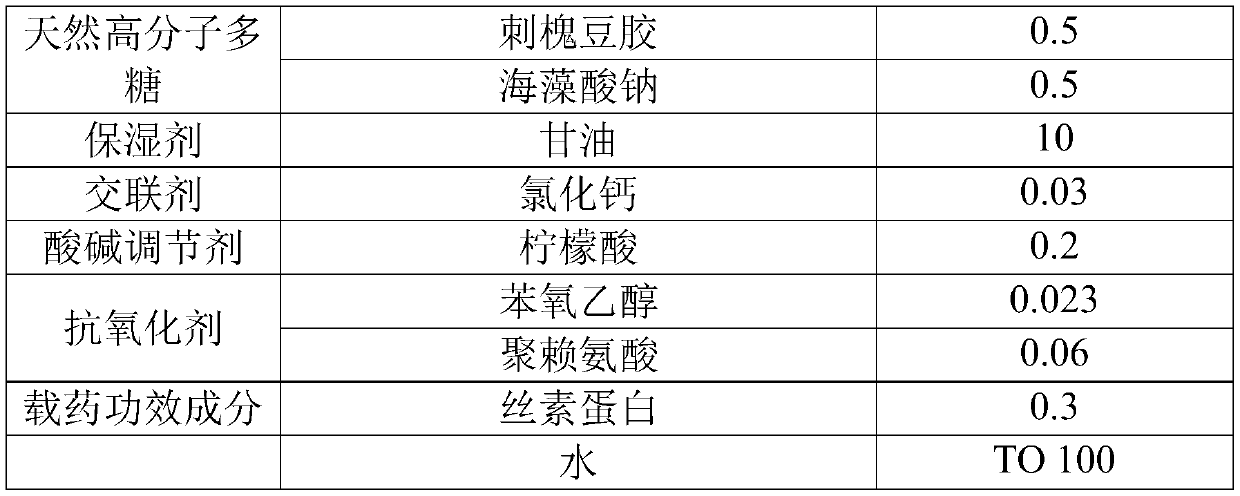

Embodiment 2

[0076]

[0077]

[0078] Step 1: Mix locust bean gum, sodium alginate and glycerin and stir until uniformly dispersed;

[0079] Step 2: Dissolve calcium chloride, citric acid, phenoxyethanol, polylysine, and silk fibroin in water and add them to the evenly dispersed mixture of locust bean gum, sodium alginate and glycerin, and make the locust Soybean gum and sodium alginate are fully stirred;

[0080] Step 3: Heat the preparation prepared in step 2 to 80°C and fully dissolve it, then keep the dissolution temperature at a constant temperature for 30 minutes, and let it stand for natural cooling until the temperature drops to 50°C and store at a constant temperature;

[0081] Step 4: Coat or cast the preparation stored at a constant temperature of 50°C in step 3 to form a film, and use microwave or infrared dehydration drying equipment to dehydrate and dry at 50°C to form a dry film, then cover with a protective film, roll into a film, cut into shape, The package is seale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com