Heavy load moving arm potential energy recovery system for large hydraulic excavator and control method thereof

A hydraulic excavator and boom potential energy technology, which is applied to fluid pressure actuation system components, mechanically driven excavators/dredgers, earth movers/shovels, etc. problems, to achieve the effect of simple structure, reduced energy consumption, and small system footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further explained below in conjunction with the accompanying drawings.

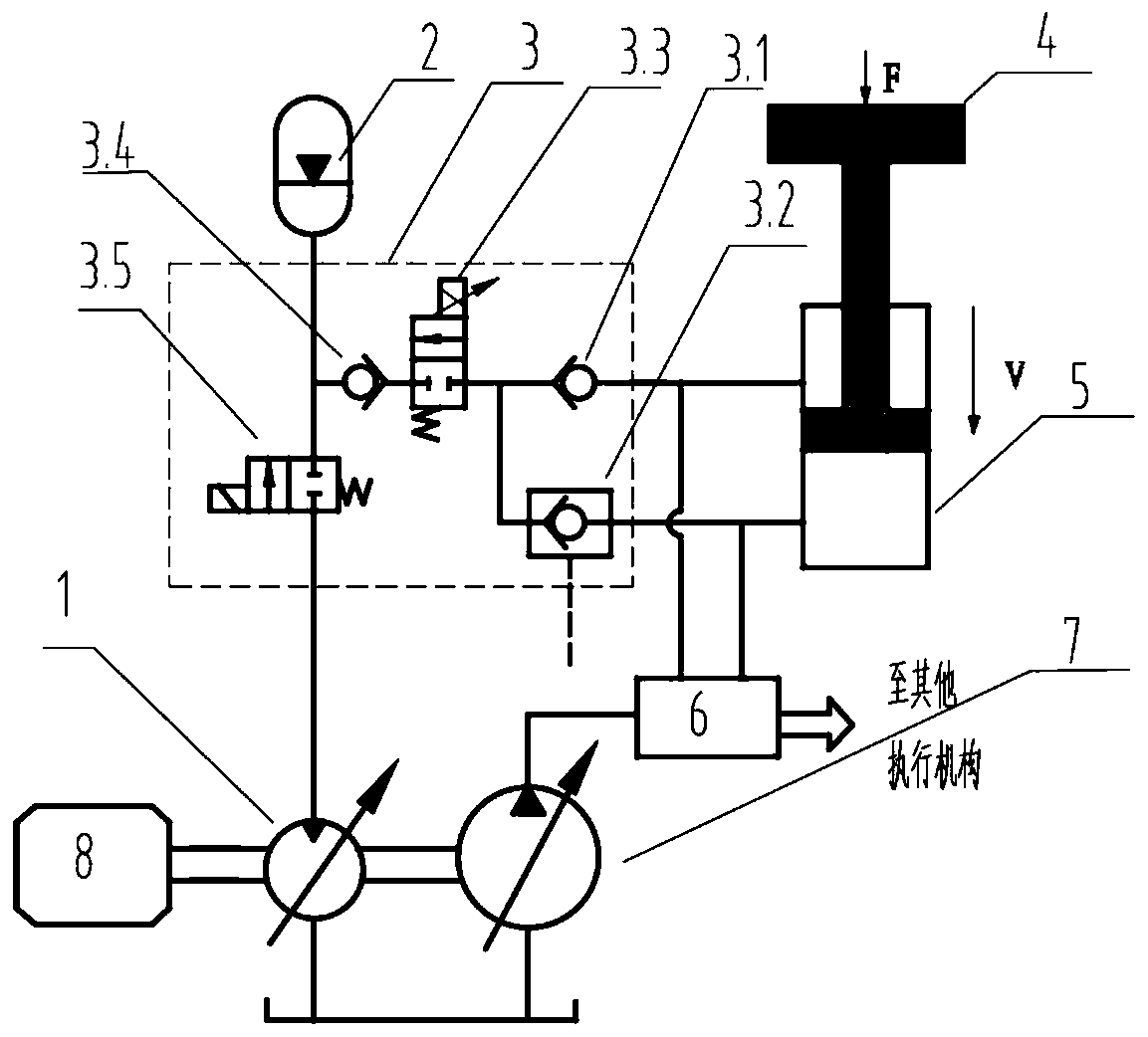

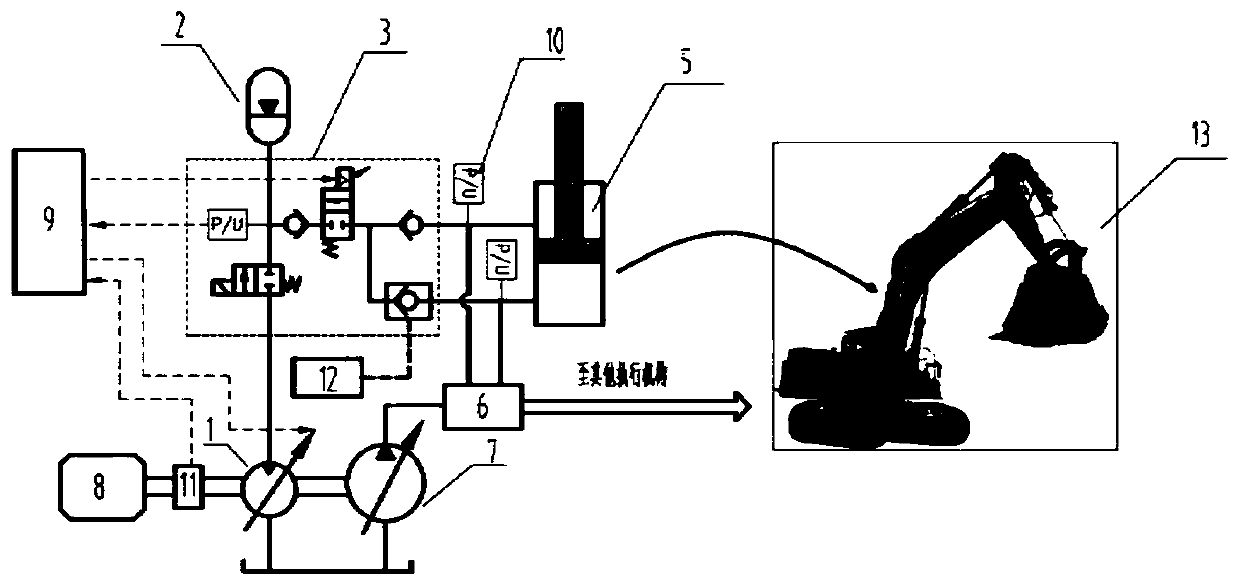

[0030] Such as figure 1 and figure 2 As shown, the heavy-duty boom potential energy recovery system of the large hydraulic excavator of the present invention is composed of an energy recovery system on the original boom hydraulic system, and is characterized in that: the original boom hydraulic system includes the boom 4 and the dynamic Boom cylinder 5, main valve 6, main pump 7 and engine 8, in which the boom 4 and the boom cylinder 5 are matched to form a complete hydraulic arm, the piston of the driven boom 4 in the boom cylinder 5 is divided into a rod chamber and a rodless chamber cavity, the pipelines of the rod cavity and the rodless cavity are respectively connected to the main pump 7 through the main valve 6, and the main pump 7 is connected to the engine 8;

[0031] The energy recovery and utilization system includes a sequentially connected variable motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com