A kind of high temperature and high humidity resistant halogen-free flame retardant polyester composite material and preparation method thereof

A technology of flame-retardant polyester and composite materials, applied in the field of polyester materials for charging piles, to achieve high production efficiency, low production cost, and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

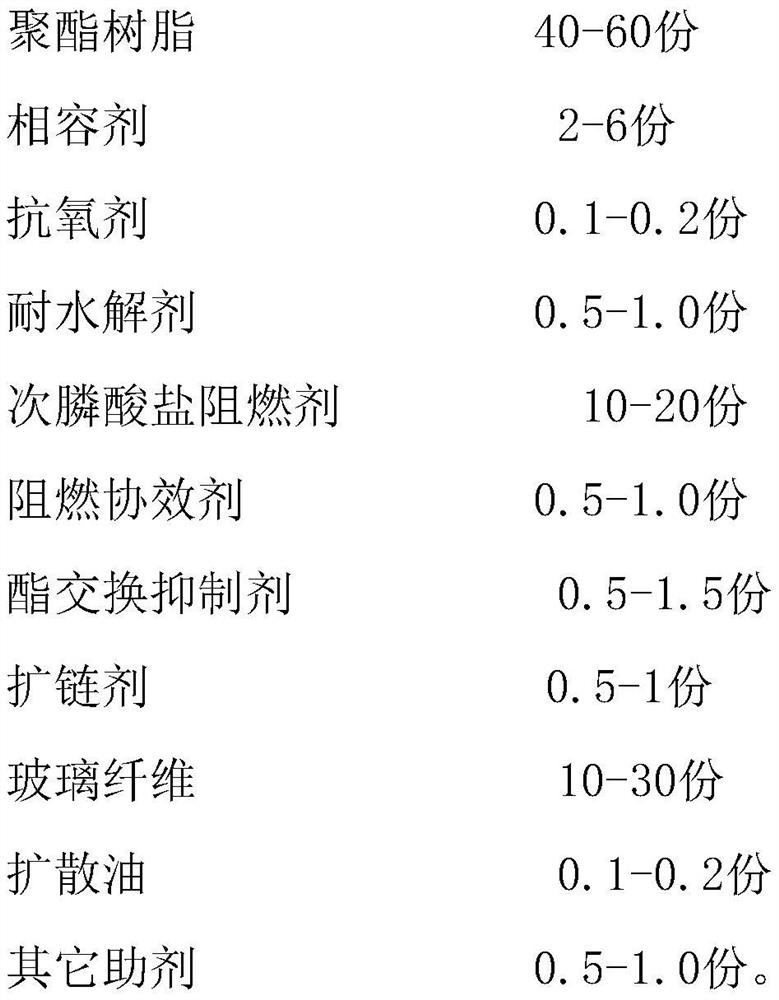

[0035] A high-temperature and high-humidity-resistant halogen-free flame-retardant polyester composite material, comprising the following raw materials in parts by weight:

[0036]

[0037]

[0038] The polyester resin is formed by mixing polybutylene terephthalate and polyethylene terephthalate at a weight ratio of 2:1. The intrinsic viscosity of polybutylene terephthalate is 0.9 dL / g, and the intrinsic viscosity of polyethylene terephthalate is 1.1 dL / g.

[0039] The compatibilizer is a mixture of glycidyl methacrylate grafted polyolefin elastomer and styrene-acrylonitrile-glycidyl methacrylate copolymer in a weight ratio of 3:1.5, and the relative The molecular weight is 8.5×10 4 . The chain extender is an acrylic-styrene copolymer containing epoxy groups; the acrylic-styrene copolymer containing epoxy groups is acrylic acid-styrene-glycidyl methacrylate copolymer.

[0040] The antioxidant is formed by mixing a hindered phenolic primary antioxidant and a sulfide se...

Embodiment 2

[0052] A high-temperature and high-humidity-resistant halogen-free flame-retardant polyester composite material, comprising the following raw materials in parts by weight:

[0053]

[0054]

[0055] The polyester resin is formed by mixing polybutylene terephthalate and polyethylene terephthalate at a weight ratio of 3:1. The intrinsic viscosity of polybutylene terephthalate is 0.7 dL / g, and the intrinsic viscosity of polyethylene terephthalate is 1.2 dL / g.

[0056] The compatibilizer is formed by mixing glycidyl methacrylate grafted polyolefin elastomer and styrene-acrylonitrile-glycidyl methacrylate copolymer in a weight ratio of 3:1. Molecular weight at 5×10 4 . The chain extender is an acrylic-styrene copolymer containing epoxy groups; the acrylic-styrene copolymer containing epoxy groups is a methacrylic acid-styrene-glycidyl methacrylate copolymer.

[0057] The antioxidant is formed by mixing a hindered phenolic primary antioxidant and a sulfide secondary antioxi...

Embodiment 3

[0069] A high-temperature and high-humidity-resistant halogen-free flame-retardant polyester composite material, comprising the following raw materials in parts by weight:

[0070]

[0071] The polyester resin is formed by mixing polybutylene terephthalate and polyethylene terephthalate at a weight ratio of 1:1. The intrinsic viscosity of polybutylene terephthalate is 1.2 dL / g, and the intrinsic viscosity of polyethylene terephthalate is 0.7 dL / g.

[0072] The compatibilizer is formed by mixing glycidyl methacrylate grafted polyolefin elastomer and styrene-acrylonitrile-glycidyl methacrylate copolymer in a weight ratio of 3:2, and the relative Molecular weight at 1×10 5 . The chain extender is an acrylic-styrene copolymer containing epoxy groups; the acrylic-styrene copolymer containing epoxy groups is acrylic acid-styrene-glycidyl methacrylate copolymer and methyl Acrylic acid-styrene-glycidyl methacrylate copolymer is mixed at a weight ratio of 1:1.

[0073] The antio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com