Benzoxazine resin-based composite material with ablation resistance and heat insulation and forming method of benzoxazine resin-based composite material

A benzoxazine resin and benzoxazine technology, applied in the field of composite materials, can solve problems such as seldom mentioned in research, fracture, and high product brittleness, and achieve flexible molecular design, good product manufacturability, and low curing The effect of shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the examples, and the present invention includes but not limited to the following examples.

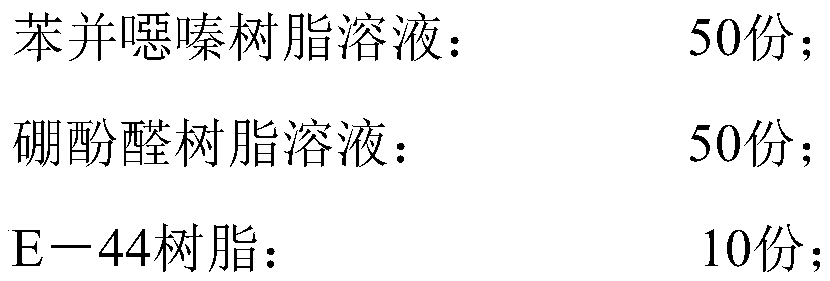

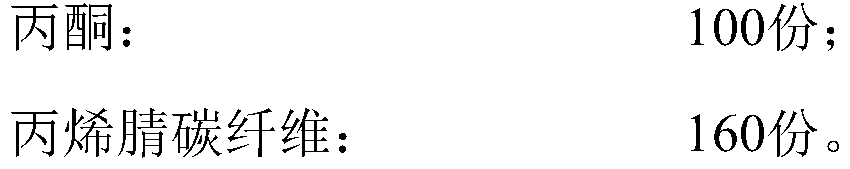

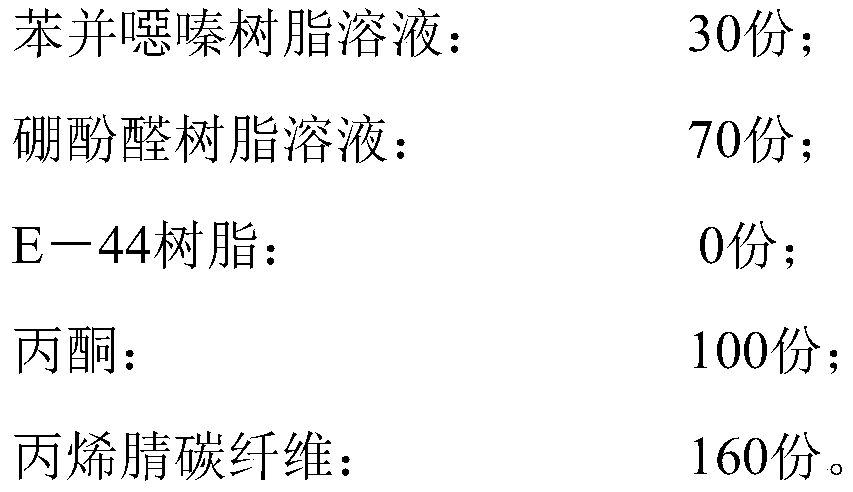

[0017] See Table 2 for the matrix components and formulations involved in the fiber-reinforced benzoxazine resin-based composite material provided by the present invention.

[0018] Table 2 Formulation design of fiber reinforced benzoxazine resin matrix composites

[0019] serial number Matrix components Proportion (weight) effect 1 Benzoxazine resin 30~40 Matrix resin 2 boron phenolic resin 60~70 Matrix resin 3 E-44 epoxy resin 0~20 toughened resin 4 acetone 100 solvent 5 Acrylonitrile carbon fiber 160 reinforced fiber

[0020] The preparation method of fiber reinforced benzoxazine resin-based composite material premix provided by the invention comprises the following steps:

[0021] Before the preparation of the mixture of the present inv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com