Method for controlling particle size of Pickering emulsion by using cellulose derivative

A technology of cellulose derivatives and emulsion particle size, applied in the field of cellulose derivatives to control the particle size of Pickering emulsions, can solve the problems of poor stability of Pickering emulsions, and achieve good stabilization effect, reduced droplet particle size, and strong interaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

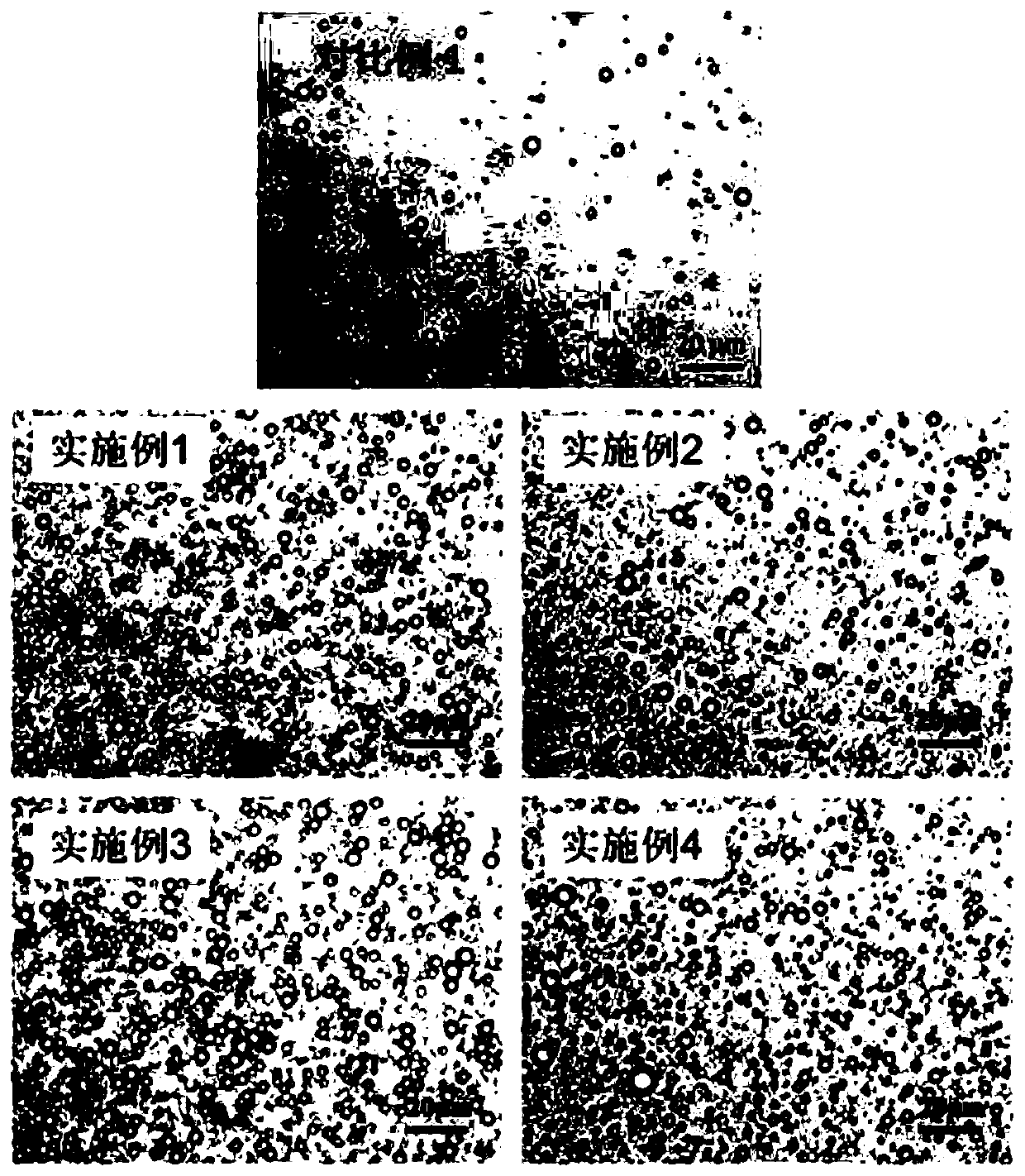

Embodiment 1

[0024] Prepare an aqueous solution of ethyl cellulose with a mass fraction of 0.5%, mix it with edible oil at a volume ratio of 9:1, and ultrasonicate for 60 seconds to obtain a Pickering emulsion. After standing for 30 minutes, take a sample and examine it under a microscope with a 40x objective lens Observe the particle size of the Pickering emulsion, and the data are shown in Table 1.

Embodiment 2

[0026] Prepare an aqueous solution of cellulose acetate with a mass fraction of 0.5%, mix it with edible oil at a volume ratio of 9:1, and ultrasonicate for 60 seconds to obtain a Pickering emulsion. After standing for 30 minutes, take a sample and observe it under a microscope with a 40x objective lens The particle size of the Pickering emulsion is shown in Table 1 for the data.

Embodiment 3

[0028] Prepare an aqueous solution of cellulose acetate propionate with a mass fraction of 0.5%, mix it with edible oil at a volume ratio of 9:1, and ultrasonicate for 60 seconds to obtain a Pickering emulsion. After standing for 30 minutes, take a sample and examine it under a microscope with a 40 times objective lens. The particle size of the Pickering emulsion was observed below, and the data are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com