Method for deep removal of chlorine in tetraethyl orthosilicate

A tetraethyl orthosilicate, deep technology, applied in the direction of silicon organic compounds, can solve the problem of high chlorine content in tetraethyl orthosilicate, and achieve the effect of low cost, strong operability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

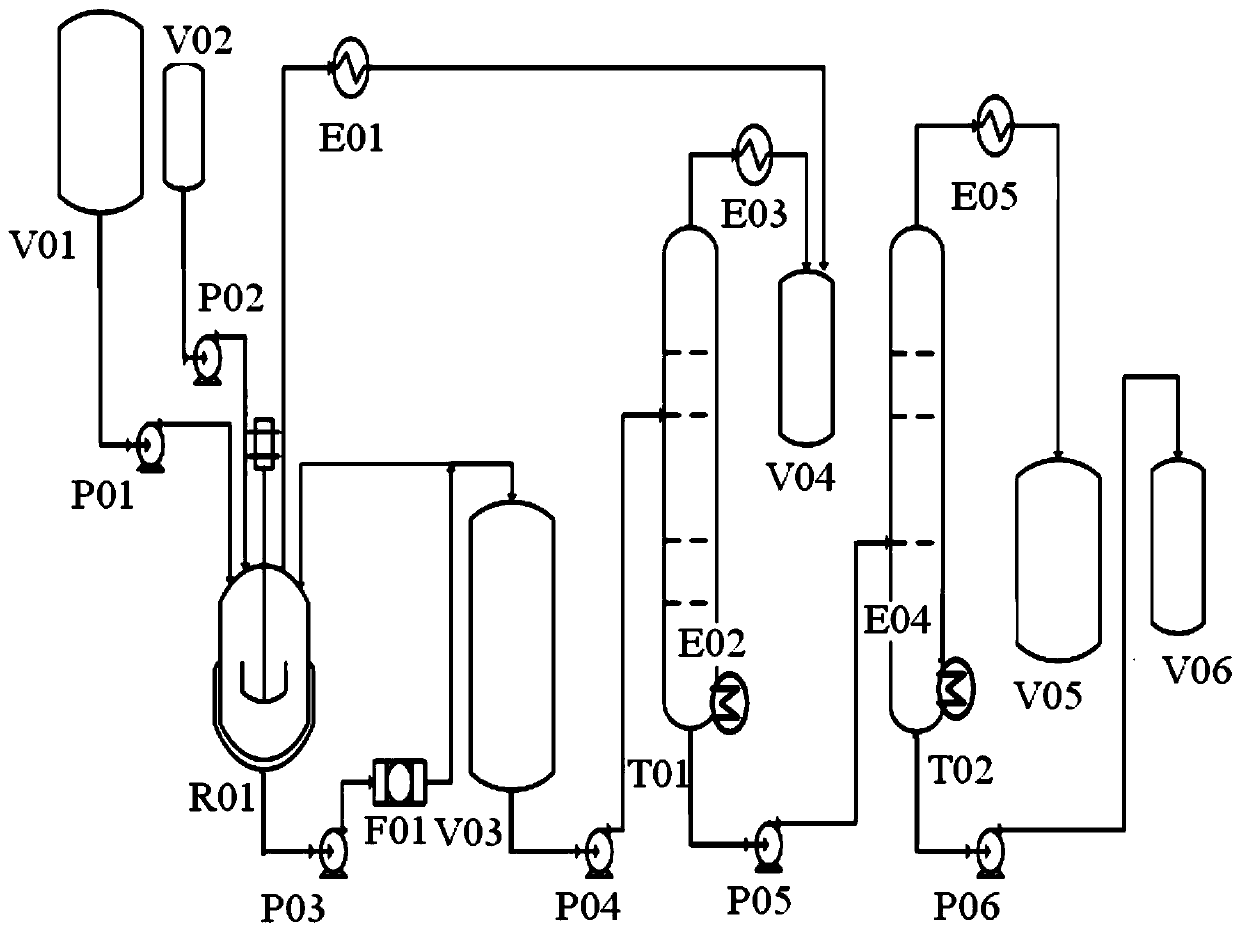

[0046] Orthoethyl silicate crude product (chlorine 461ppb, water 125ppm) enters reaction kettle R01 from TEOS raw material tank V01 through feed delivery pump P01, and sodium ethylate solution (17% ethanol solution of sodium ethylate) enters from sodium ethylate solution tank V02 The material delivery pump P02 enters the reactor R01; the mass ratio of sodium ethoxide to TEOS crude product is 0.05%; in the reactor, first react at 45°C for 0.5 hours, and gradually raise the temperature to 120°C after the first step of reaction, and continue to react for 2 hours; The pressure in the reactor was maintained at 0.15 MPa, and 6N nitrogen was used to protect and control the pressure.

[0047] After the reaction, the material is discharged through the reactor discharge pump P03, and the reacted material is filtered through the filter F01 with a pore size of 0.5 μm to remove the formed particles such as sodium chloride, and the liquid phase enters the intermediate tank V03. The material...

Embodiment 2

[0050] Orthoethyl silicate crude product (chlorine 384ppb, water 118ppm) enters reactor R01 from TEOS raw material tank V01 through feed delivery pump P01, and sodium ethylate solution (18% ethanol solution of sodium ethylate) enters from sodium ethylate solution tank V02. The material delivery pump P02 enters the reactor R01; the mass ratio of sodium ethoxide to crude TEOS is 0.08%; in the reactor, first react at 50°C for 0.5 hours, and gradually raise the temperature to 110°C after the first step of reaction, and continue to react for 2 hours; The pressure in the reactor was maintained at 0.1 MPa, and 6N nitrogen was used to protect and control the pressure.

[0051] After the reaction, the material is discharged through the reactor discharge pump P03, and the reacted material is filtered through the filter F01 with a pore size of 0.5 μm to remove the formed particles such as sodium chloride, and the liquid phase enters the intermediate tank V03. The material in the intermed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com