Injection molding machine and electric injection device thereof

An injection device and electric technology, applied in the field of injection molding machines and their electric injection devices, can solve the problems of affecting injection quality and difficult to achieve synchronization, and achieve the effects of improving injection quality, improving precision, and increasing contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

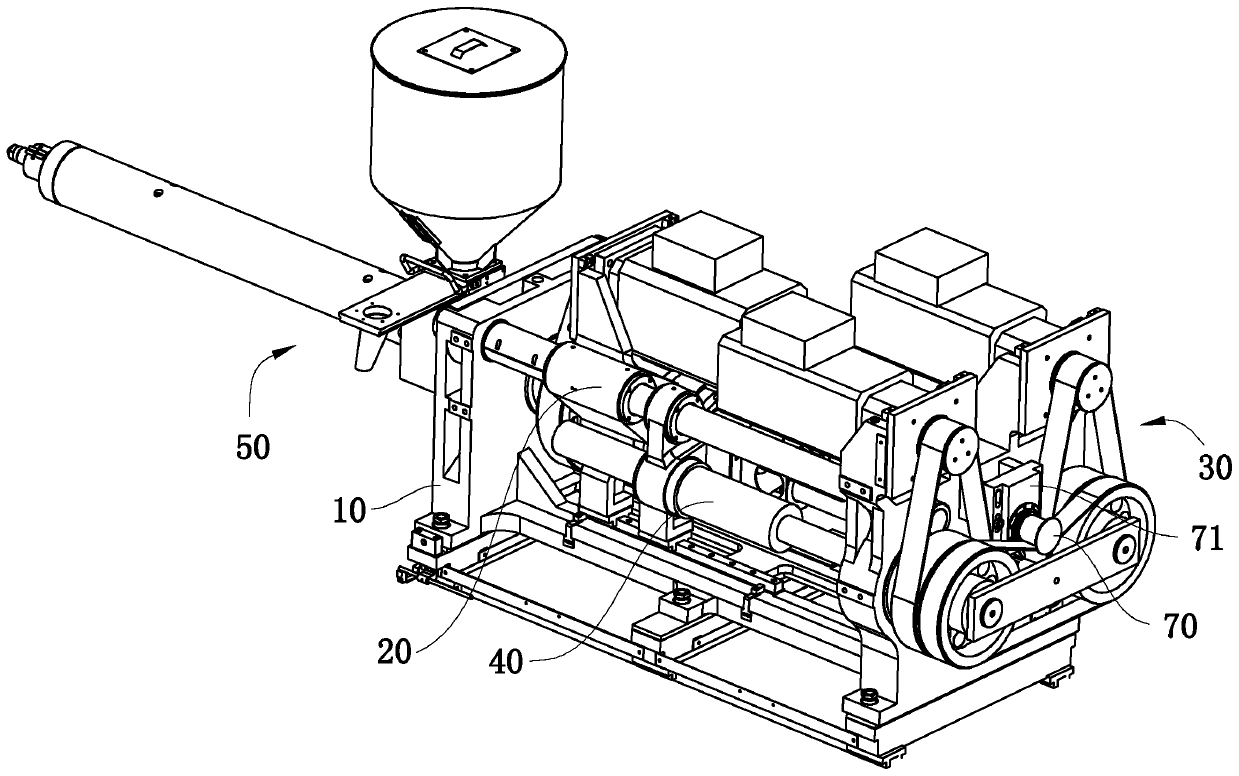

[0077] refer to figure 1 , shows the structure of an electric injection device, including an integrated base 10 , an injection seat 20 inside the base 10 , an injection mechanism 50 connected to the injection seat 20 and a driving mechanism 30 . The driving mechanism 30 is connected with a screw assembly 40, and the screw assembly 40 is connected with the injection seat 20, and the injection seat 20 is driven to be displaced by the driving mechanism 30 to realize the injection process.

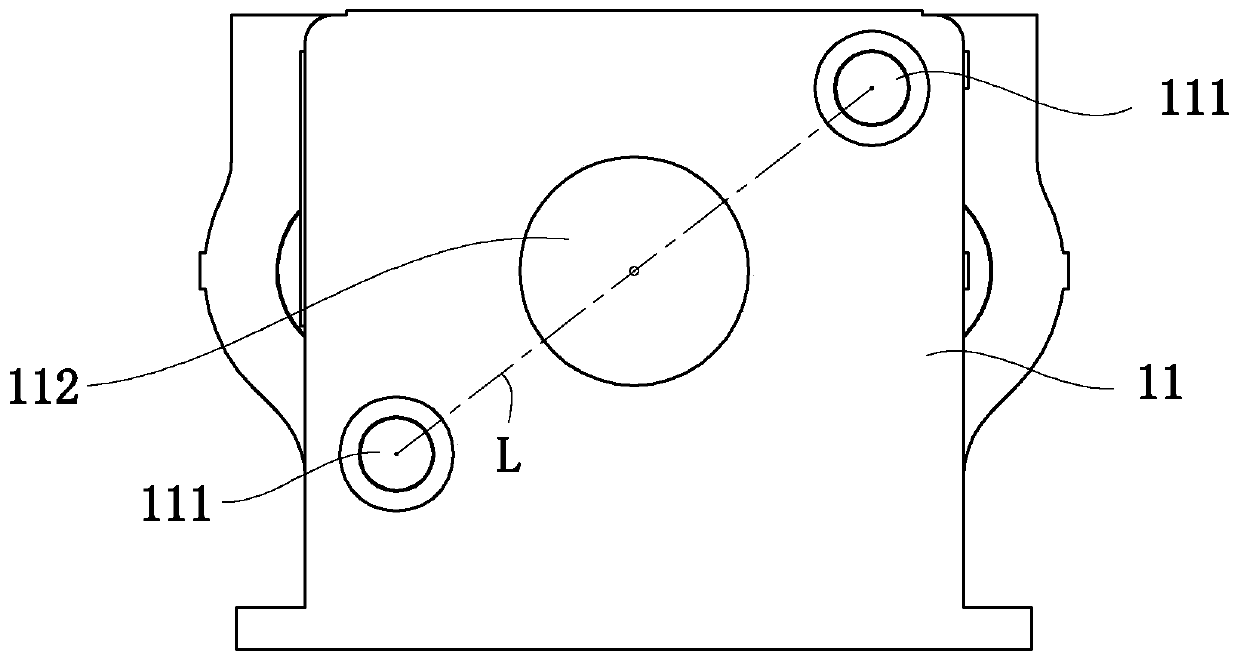

[0078] common reference figure 2 and image 3 , the base 10 is roughly in the shape of a "U" and includes a front plate 11 and a tail plate 12 separated by a certain distance. 11 and tail plate 12. There is also a pull rod set between the front plate 11 and the tail plate 12, two pull rod installation holes 111 are opened on the front plate 11 and the tail plate 12 in a diagonal manner, and a barrel hole 112 is also opened on the front plate 11 , the connecting line between the centers of...

Embodiment 2

[0100] An injection molding machine includes the electric injection device in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com