A kind of hydrotalcite and preparation method thereof and application of hydrotalcite in adsorbing pfos pollutants in water body

A technology for hydrotalcite and pollutants, applied in the fields of water pollutants, adsorbed water/sewage treatment, water/sewage treatment, etc., can solve the problems of poor efficiency and expensive ion exchange resin materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

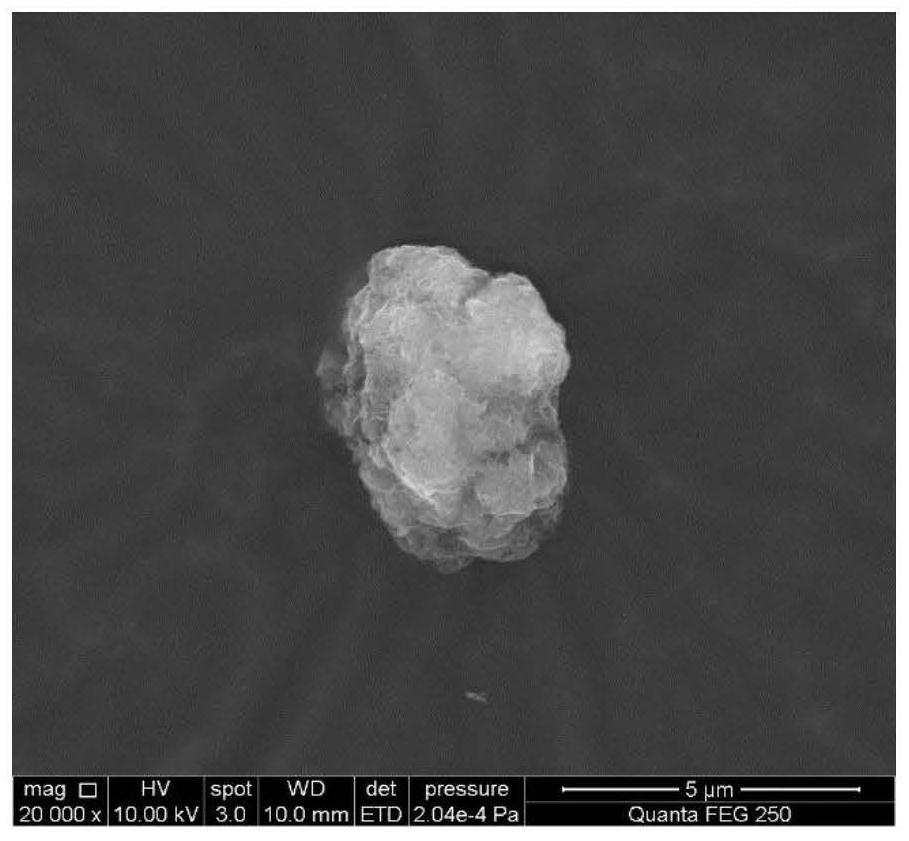

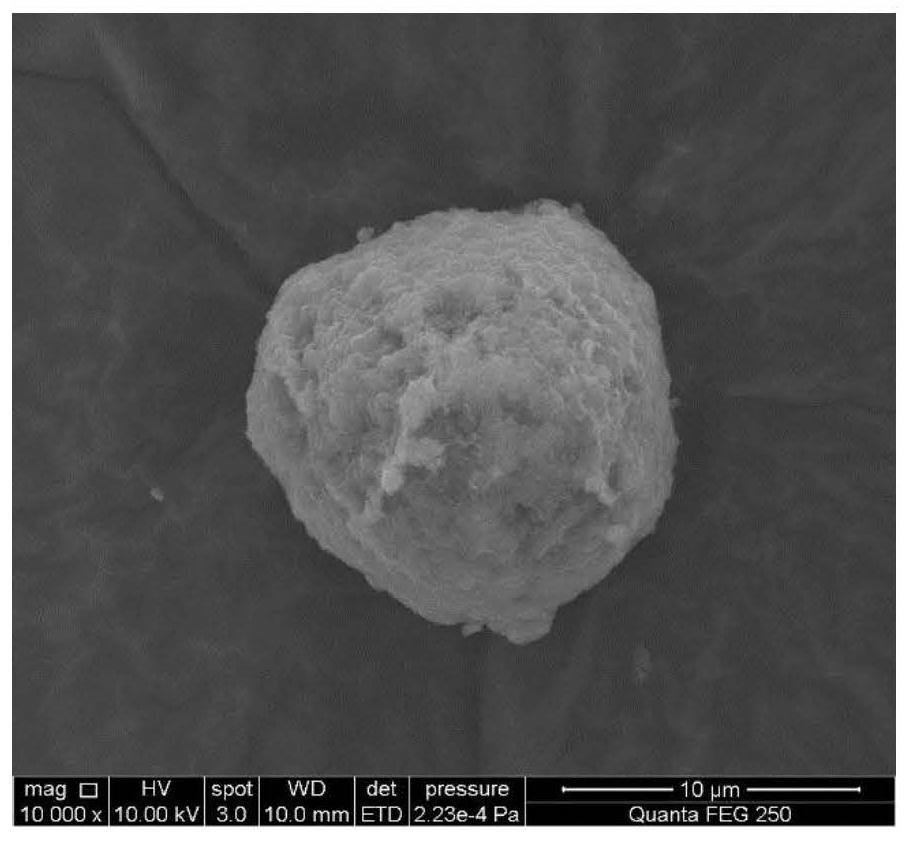

Image

Examples

Embodiment 1

[0037] The preparation method of hydrotalcite of the present invention comprises the following steps:

[0038] 1) Take the raw material aluminum nitrate nonahydrate Al(NO 3 ) 3 9H 2 O and magnesium nitrate hexahydrate Mg(NO 3 ) 2 ·6H 2 O and deionized water;

[0039] Among them, the molecular weight of aluminum nitrate nonahydrate is 375.13, and the molecular weight of magnesium nitrate hexahydrate is 256.41;

[0040] 2) Mix aluminum nitrate nonahydrate and magnesium nitrate hexahydrate in 50 ml of deionized water at a molar ratio of 1:2, and add appropriate amount of ammonia water NH under magnetic stirring 3 ·H 2 O makes the mixed solution evenly mix at pH 11;

[0041] 3) After continuous mixing for 30 minutes, the mixture was transferred into a high-pressure steam pot (Teflon-lined stainless steel autoclave), maintained at a temperature of 200°C for 20 hours, and then naturally cooled to room temperature to obtain a wet white powder solid;

[0042] 4) The white pow...

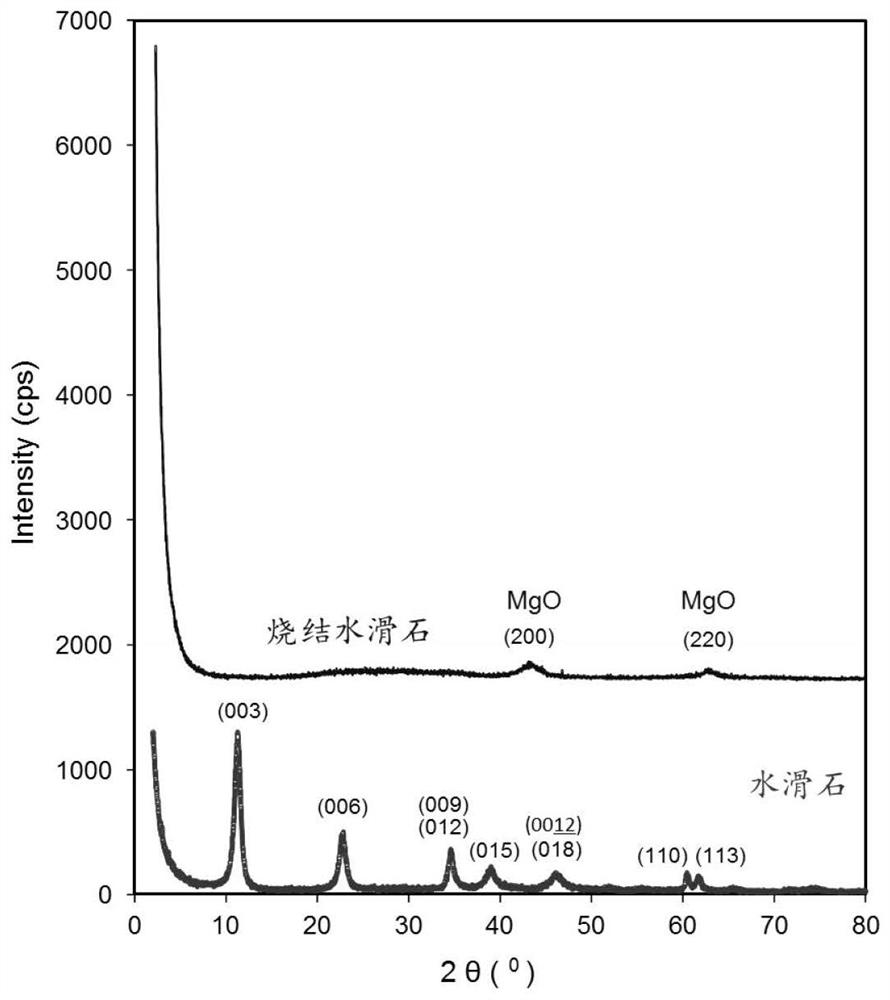

Embodiment 2

[0046] The steps are the same as in Example 1, except that the molar ratio of aluminum nitrate nonahydrate and magnesium nitrate hexahydrate in Example 1 is changed to 1:3 for mixing. Then the dry white powder-hydrotalcite whose characterization data is as follows Figure 4 shown.

Embodiment 3

[0048] The steps are the same as in Example 1, except that the molar ratio of aluminum nitrate nonahydrate and magnesium nitrate hexahydrate in Example 1 is changed to a ratio of 1:1 and the dry white powder-hydrotalcite is obtained. The characterization data are as follows: Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com