Variable-diameter spinneret, hollow fiber membrane tow processing device and membrane module processing device

A processing device and spinneret technology, applied in spinneret assemblies, hollow filament manufacturing, fiber processing, etc., can solve the problems of mechanization of hollow fiber membrane module processing, poor consistency of module performance, and low packing density. To achieve the effect of regular arrangement of filling density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

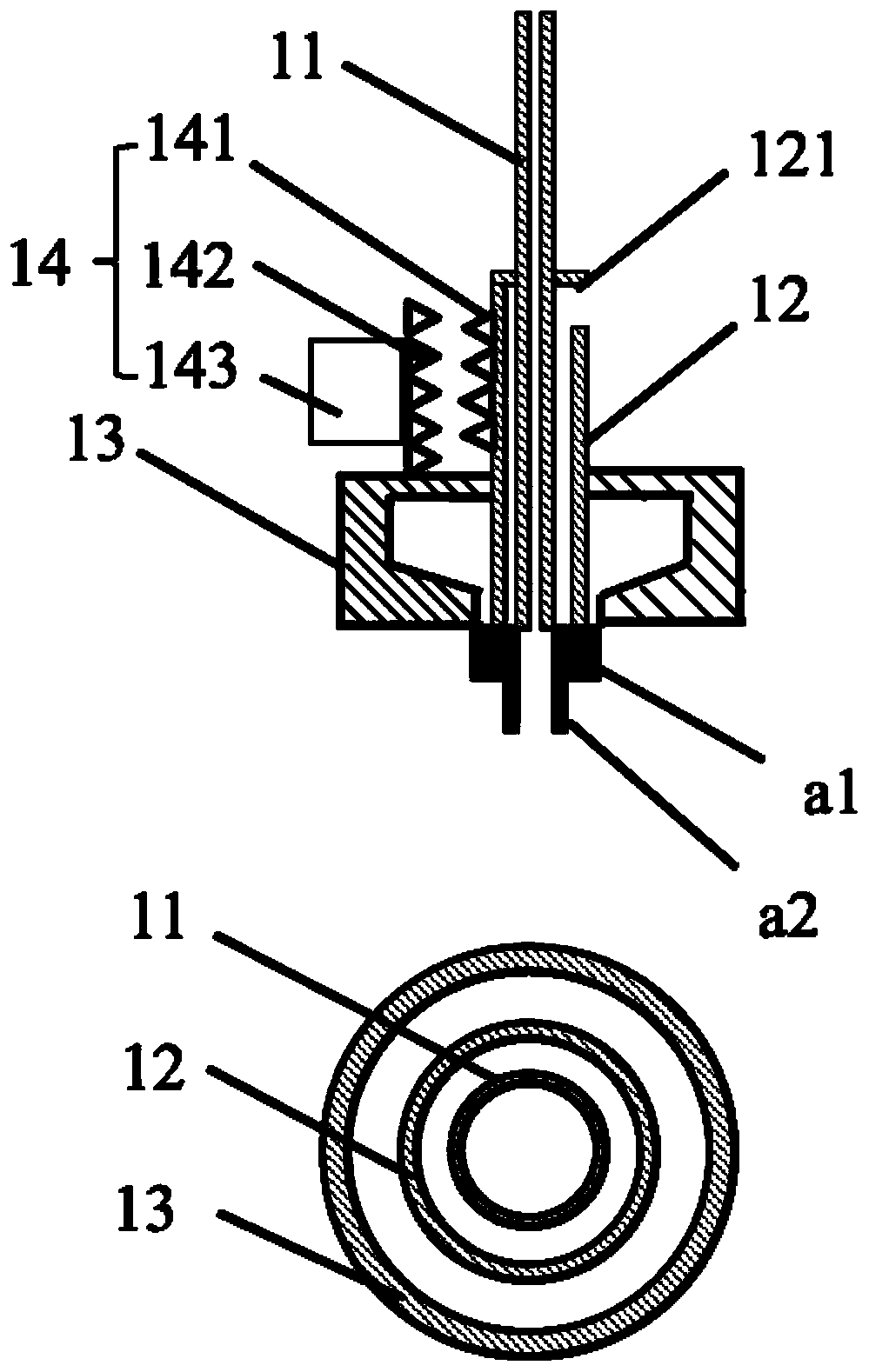

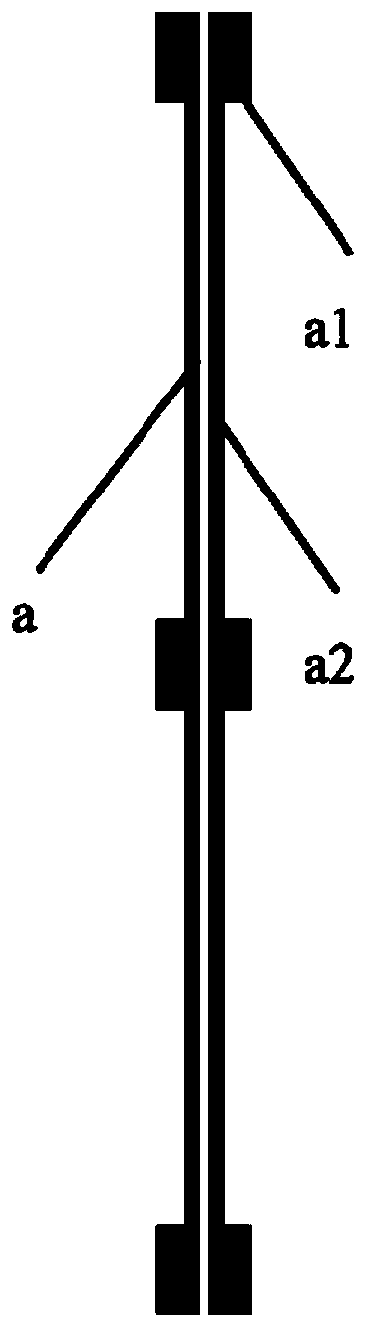

[0063] Such as figure 1 and 2 As shown, this embodiment provides a variable-diameter spinneret, including a central tube 11, an intermediate tube 12, and an external cavity 13 that are sheathed in sequence, and a first drive mechanism that drives the intermediate tube 12 to move vertically up and down. 14. The bottoms of the central tube 11, the middle tube 12 and the outer cavity 13 are flush.

[0064] In this embodiment, the top of the intermediate circular tube 12 is sealed, and a feeding port 121 for feeding is provided on the upper part.

[0065] In this embodiment, the intermediate tube 12 protrudes from the central tube 11 and the outer cavity 13, and the first driving mechanism 14 includes a rack 141 arranged on the protruding part of the intermediate tube 12, and is engaged with the rack 141. The gear 142 and the first motor 143 that drives the gear 142 move, the first motor 143 drives the gear 142 to move, and through the rack and pinion transmission, the vertical ...

Embodiment 2

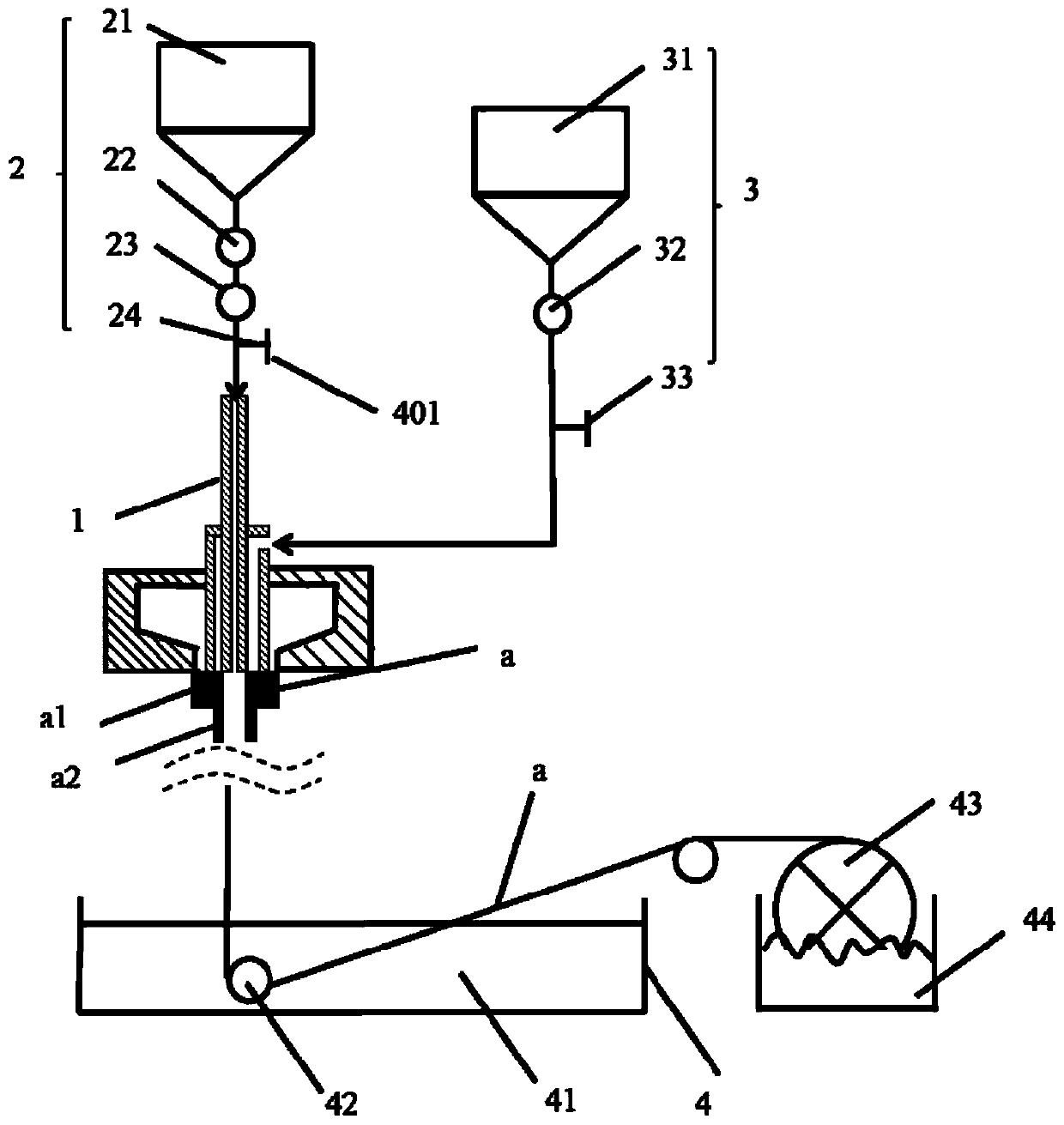

[0070] In this embodiment, on the basis of implementation 1, refer to image 3 , 4 And 5, also provide a kind of processing device of hollow fiber membrane tow, comprise variable-diameter spinneret 1 among the embodiment 1, be used for the first feeding mechanism 2 of center tube 11 feeding, be used for The second feeding mechanism 3 fed by the middle circular tube 12, the collection structure 4 for collecting the membrane filaments spun by the variable diameter spinneret 1, and the collection structure 4 for cutting the membrane filaments on the collection structure 4 into membrane filament segments The cutting mechanism 5 and the automatic strapping machine 6 for bundling the film wire segments.

[0071] In this embodiment, the first feeding mechanism 2 includes an inner coagulation bath 21 communicated with the upper part of the central tube 11; The flow meter 22, the first pump 23 and the first valve 24, the first feeding mechanism can realize continuous feeding to the c...

Embodiment 3

[0082] refer to Figure 6 , this embodiment also provides a processing device for hollow fiber membrane modules, including a processing device for hollow fiber membrane tows in Embodiment 2, a membrane module 7 for accommodating membrane tows, a dispensing mechanism 8 and a device for cutting membrane filaments The second shearing mechanism 9 for the beam.

[0083] Specifically, the hollow fiber membrane filaments are placed in the membrane module, glue is dispensed by a glue dispenser, and then the membrane filament ends at both ends of the strap are cut by the second shearing structure to obtain the hollow fiber membrane module.

[0084] In this embodiment, the membrane module 7 includes a membrane module housing 71 with open upper and lower parts, sealing plates 72 detachably arranged at both ends of the membrane module housing 71 , sleeves on the upper end surface and the lower end surface of the membrane module housing 71 Assembly head 73.

[0085] Specifically, the mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com