Plastic plug-in connector and method for producing it

A plug connector, plastic technology, used in couplings, other household appliances, household components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

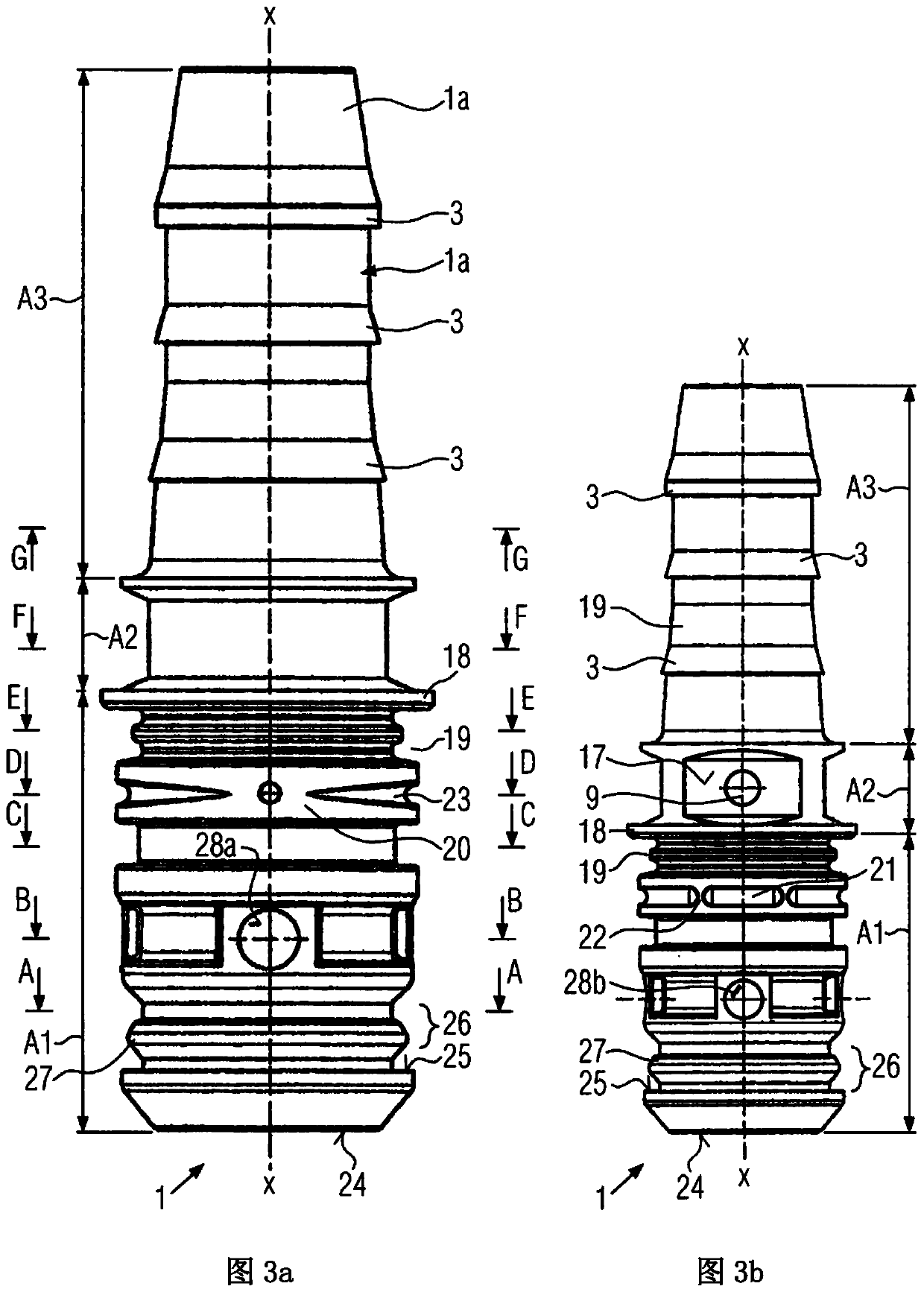

[0050] In the individual figures of the drawings, identical components are always assigned the same reference symbols and are therefore generally described only once. With regard to the following description, it is hereby claimed that the invention is not limited to the described embodiments and in this case not to all or more features of the described combination of features, but rather each individual partial feature of the described embodiments Separately from all other partial features described in connection with it, it is also combined with other features that are essential to the subject matter of the invention.

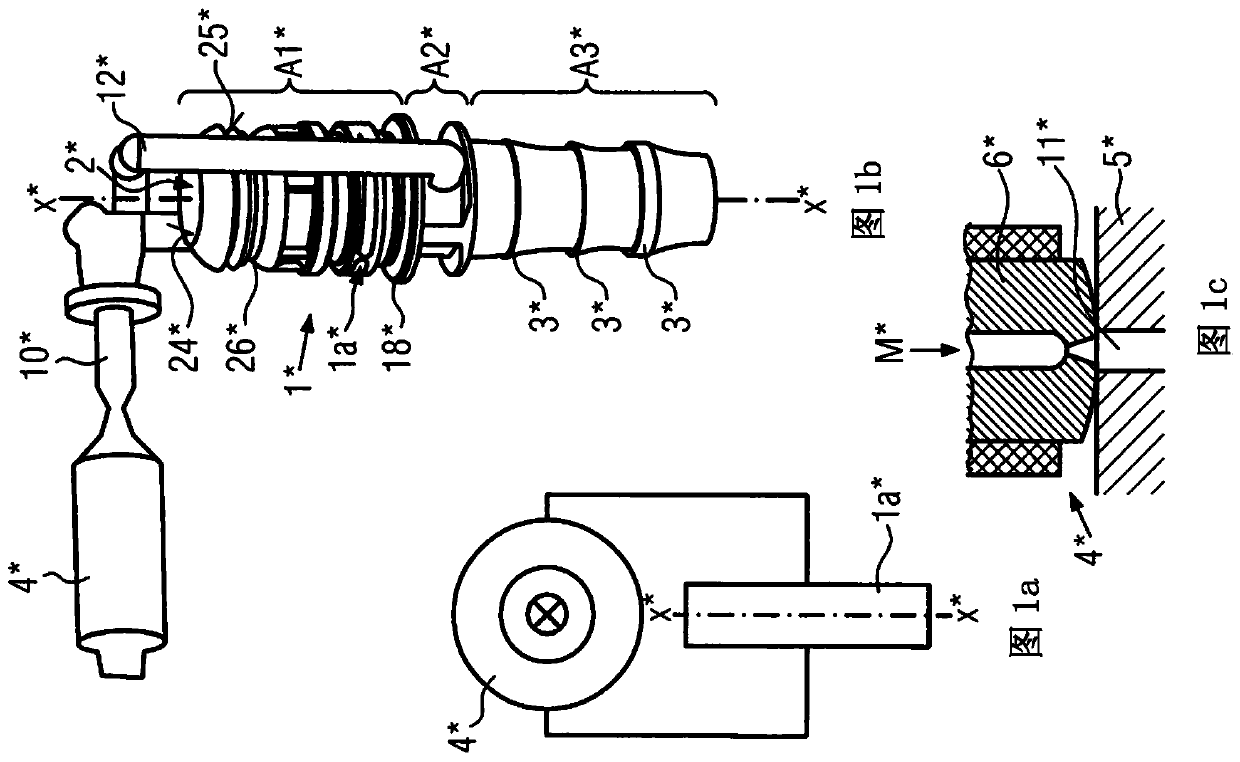

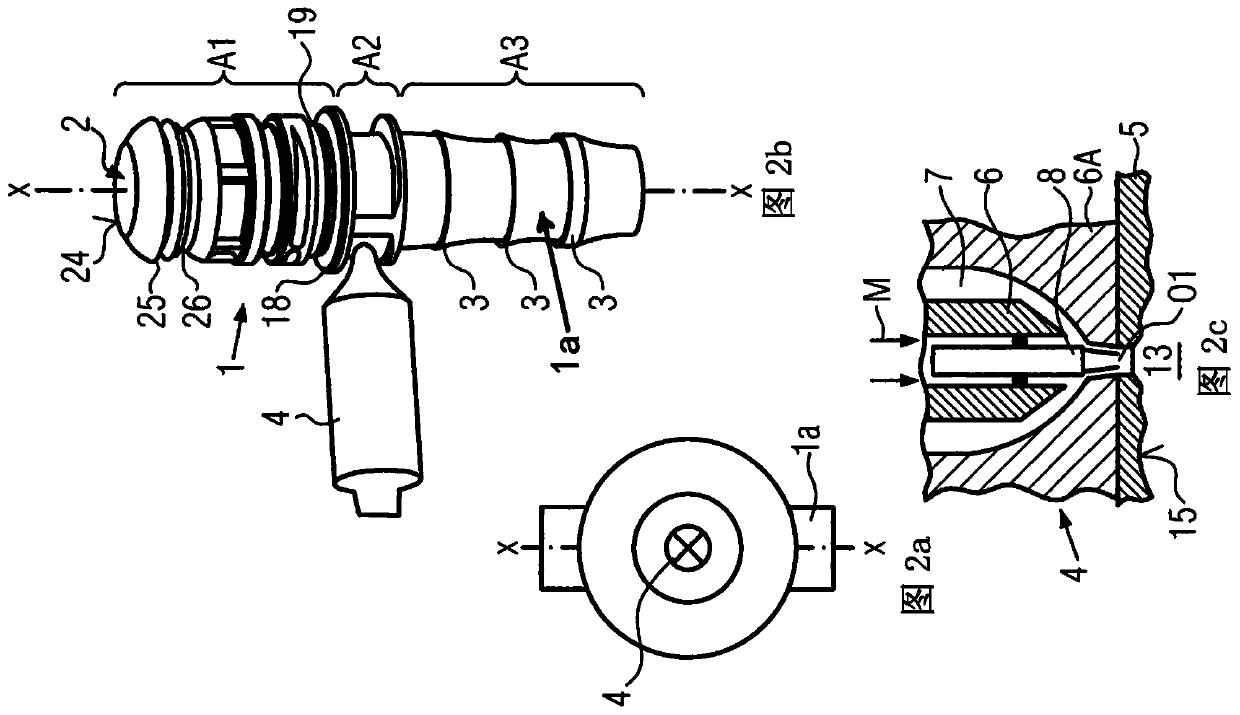

[0051] as in Figures 1a to 1c and Figures 2a to 2c As shown in , the invention relates to a plug-in connector 1 which is designed as a molded part 1a made of plastic, produced by injection molding, and has an inner channel 2 for a fluid and an at least partially annular cross section Q. The different sectional views through cross-sections are shown in 4a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com