Composite bipolar plate conductive plastic plate and preparation method and preparation equipment thereof

A technology of conductive plastics and bipolar plates, applied in circuits, fuel cells, electrical components, etc., can solve the problems of high softening temperature of conductive plastics, large heat generation of bipolar plates, embedded conductive felt, etc., to improve compatibility, The effect of reducing accident rate and resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In this embodiment, a conductive plastic plate 101 suitable for a composite bipolar plate includes the following components by weight:

[0045] 37g of polyethylene, 12g of superconducting carbon black, 30g of conductive graphite, 8g of carbon nanotubes, 5g of PE-g-MAH compatibilizer, and 8g of POE toughening agent.

[0046] The preparation method is as follows:

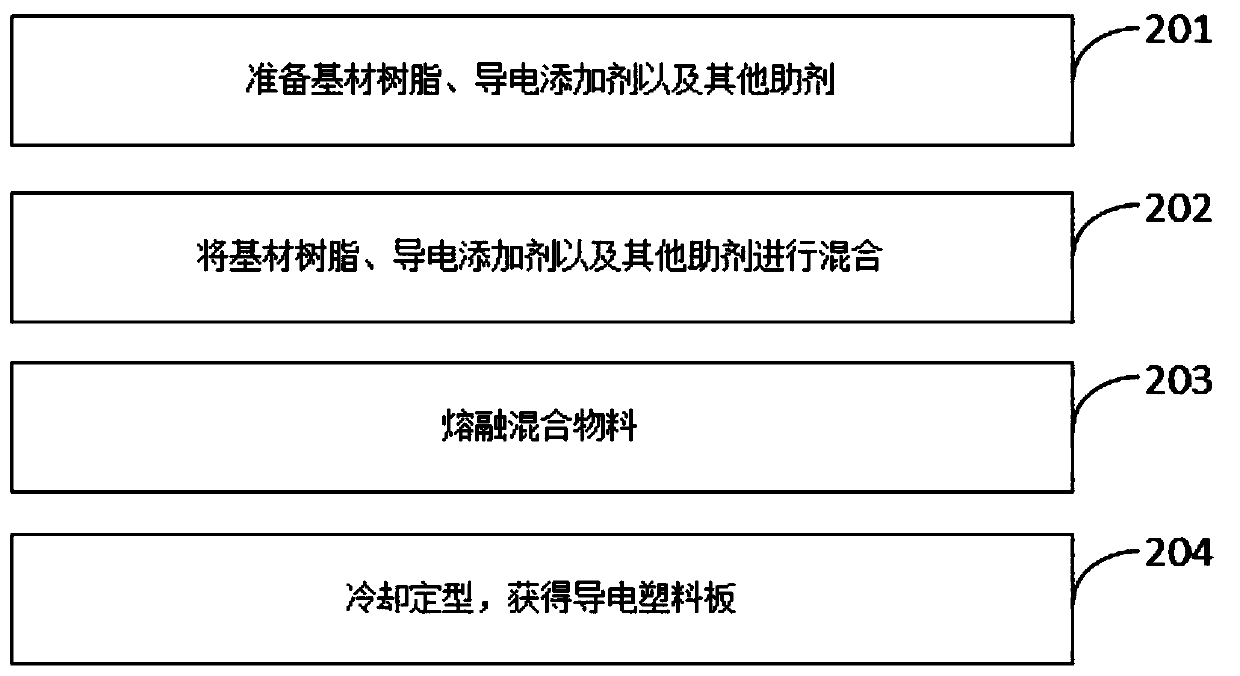

[0047] Material preparation 201: prepare each component according to the above weight;

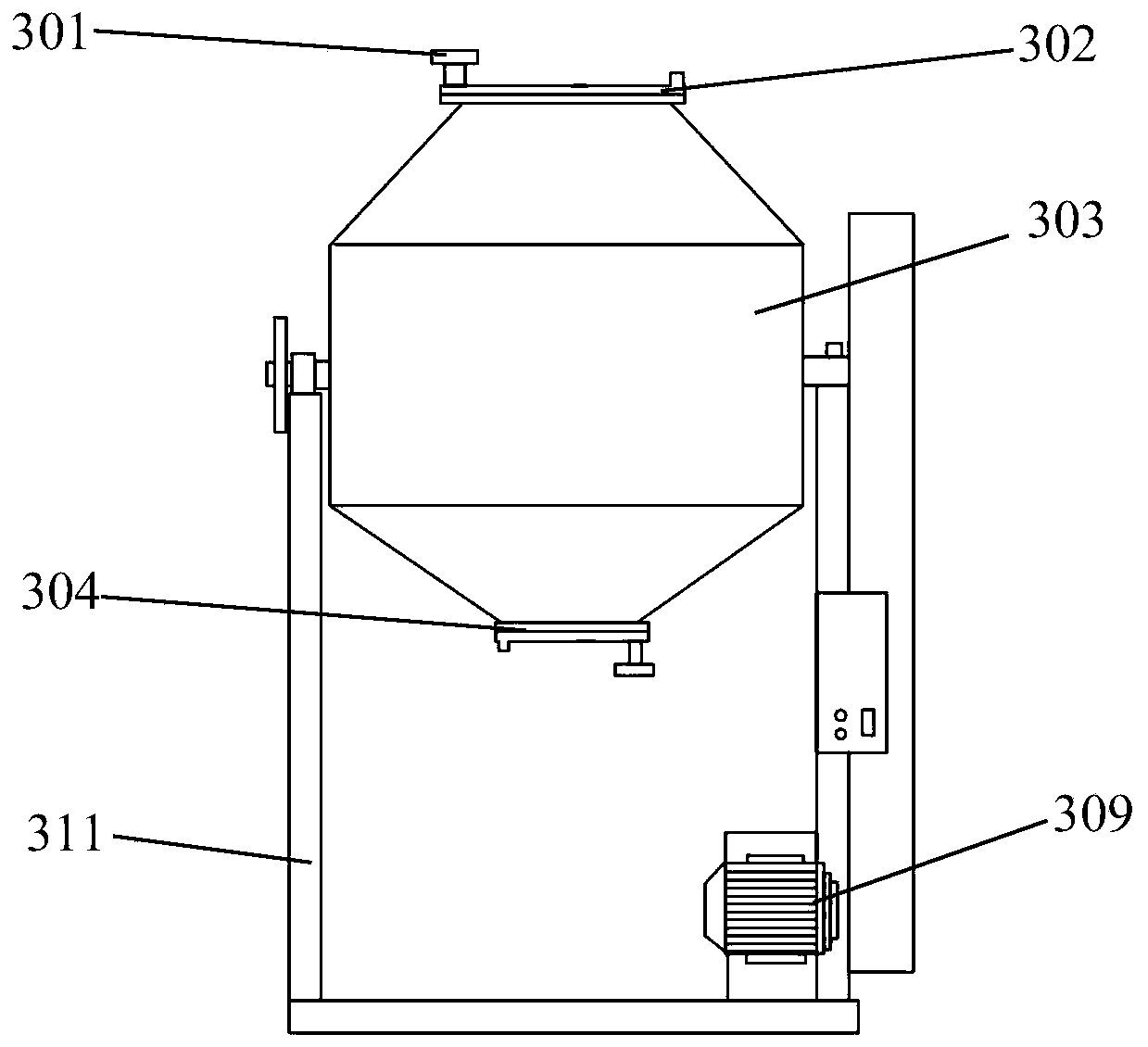

[0048]Mixing 202: close the discharge cover 304 and then close the discharge port, open the feed cover and add the above-mentioned materials into the cylinder 303 from the feed port, start the motor 309, and drive the motor wheel 308, the first belt 312, the second A driven wheel 307, a second belt 306 and a second driven wheel 305 further drive the rotating shaft to make the entire cylinder 303 rotate with the rotating shaft as the axis, fully mix 202 the materials inside the cylinder 303, close the motor 309 after mixing...

Embodiment 2

[0054] In this embodiment, a conductive plastic plate 101 suitable for a composite bipolar plate includes the following components by weight:

[0055] 40g of polypropylene, 10g of superconducting carbon black, 25g of conductive graphite, 10g of carbon nanotubes, 4g of PE-g-MAH compatibilizer, and 15g of POE toughening agent.

[0056] The preparation method is as follows:

[0057] Material preparation 201: prepare each component according to the above weight;

[0058] Mixing 202: close the discharge cover 304 and then close the discharge port, open the feed cover and add the above-mentioned materials into the cylinder 303 from the feed port, start the motor 309, and drive the motor wheel 308, the first belt 312, the second A driven wheel 307, a second belt 306 and a second driven wheel 305 further drive the rotating shaft to make the entire cylinder 303 rotate with the rotating shaft as the axis, fully mix 202 the materials inside the cylinder 303, close the motor 309 after mi...

Embodiment 3

[0063] In this embodiment, a conductive plastic plate 101 suitable for a composite bipolar plate includes the following components by weight:

[0064] 48g of polyethylene, 15g of superconducting carbon black, 28g of conductive graphite, 6g of carbon nanotubes, 8g of PE-g-MAH compatibilizer, and 15g of POE toughening agent.

[0065] The preparation method is as follows:

[0066] Material preparation 201: prepare each component according to the above weight;

[0067] Mixing 202: close the discharge cover 304 and then close the discharge port, open the feed cover and add the above-mentioned materials into the cylinder 303 from the feed port, start the motor 309, and drive the motor wheel 308, the first belt 312, the second A driven wheel 307, a second belt 306 and a second driven wheel 305 further drive the rotating shaft to make the entire cylinder 303 rotate with the rotating shaft as the axis, fully mix 202 the materials inside the cylinder 303, close the motor 309 after mixi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com