A method for quantitative determination of entanglement degree of ultra-high molecular weight polyethylene resin

A technology of ultra-high molecular weight and polyethylene resin, applied in the preparation of test samples, measuring devices, and analysis materials, etc., can solve the problems of complex implementation steps and large errors, and achieve high-efficiency evaluation standards, reliable data, and simple methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

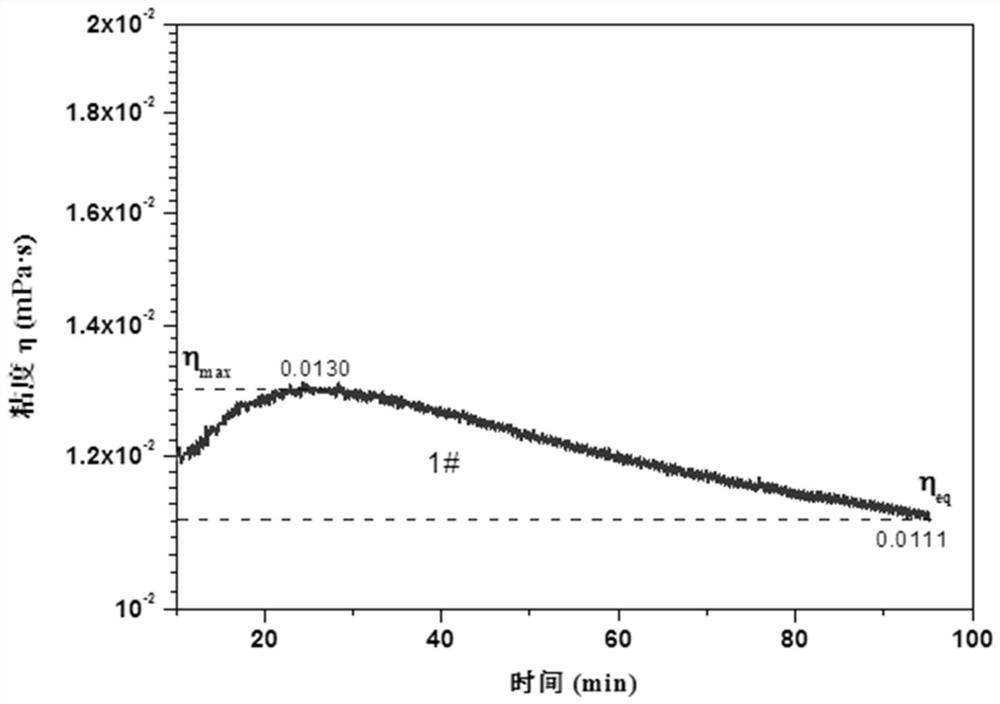

Embodiment 1

[0028] Take 1# UHMWPE (viscosity average molecular weight is 0.5×10 6 g / mol) resin 3g, get 27g paraffin oil as solvent, add antioxidant 168, mass concentration is 1wt.%, UHMWPE powder, paraffin oil, antioxidant are added in the measuring cup, form semi-dilute solution (UHMWPE concentration is 10wt. .%), using an anti-settling design stirring paddle, setting the stirring rate to 100rpm / min, rapidly raising the temperature to 200°C at a heating rate of 50°C / min, and obtaining the change curve of the viscosity of the system with time at a constant temperature of 200°C, as figure 1 Shown, (η max -η eq ) / η max The ratio of is 0.146, so as to quantitatively measure the degree of entanglement of 1# UHMWPE resin itself.

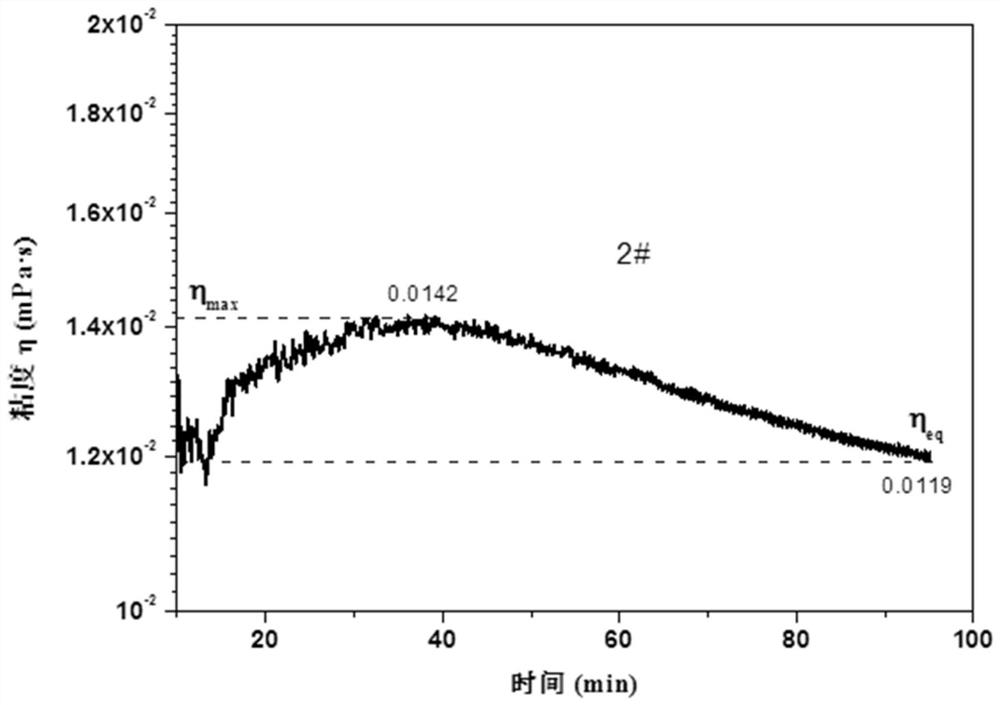

Embodiment 2

[0030] Take 2#UHMWPE (viscosity average molecular weight is 1.5×106 g / mol) resin 3g, get 27g paraffin oil as solvent, add antioxidant 168, mass concentration is 1wt.%, UHMWPE powder, paraffin oil, antioxidant are added in the measuring cup, form semi-dilute solution (UHMWPE concentration is 10wt. .%), using an anti-settling design stirring paddle, setting the stirring rate to 100rpm / min, rapidly raising the temperature to 200°C at a heating rate of 50°C / min, and obtaining the change curve of the viscosity of the system with time at a constant temperature of 200°C, as figure 2 Shown, (η max -η eq ) / η max The ratio of is 0.162, so as to quantitatively measure the degree of entanglement of 2# UHMWPE resin itself.

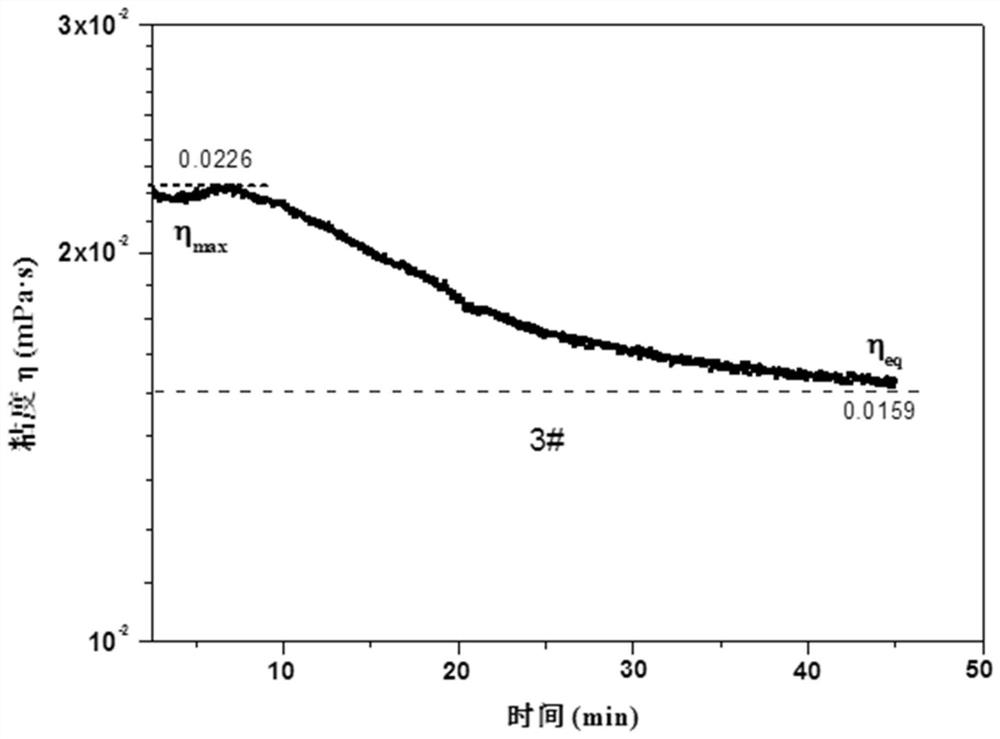

Embodiment 3

[0032] Take 3# UHMWPE (viscosity-average molecular weight is 4×10 6 g / mol) resin 0.3g, get 29.7g paraffin oil as solvent, add antioxidant 1010, mass concentration is 1wt.%, UHMWPE powder, paraffin oil, antioxidant are added in the measuring cup, form semi-dilute solution (UHMWPE concentration 1wt.%), set the stirring rate as 400 rpm / min, rapidly heat up to 200°C at a heating rate of 80°C / min, and obtain the change curve of the viscosity of the system with time at a constant temperature of 200°C, as image 3 Shown, (η max -η eq ) / η max The ratio of is 0.296, so as to quantitatively measure the degree of entanglement of 3# UHMWPE resin itself.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com