Preparation method of fully biodegradable copolyester

A copolyester and all-biological technology, which is applied in the field of preparation of all-biodegradable copolyester, can solve the problems of poor tensile yield strength, tear resistance and light transmission performance, so as to improve the polymerization reaction rate without affecting the thermal The effect of stability and guaranteed yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

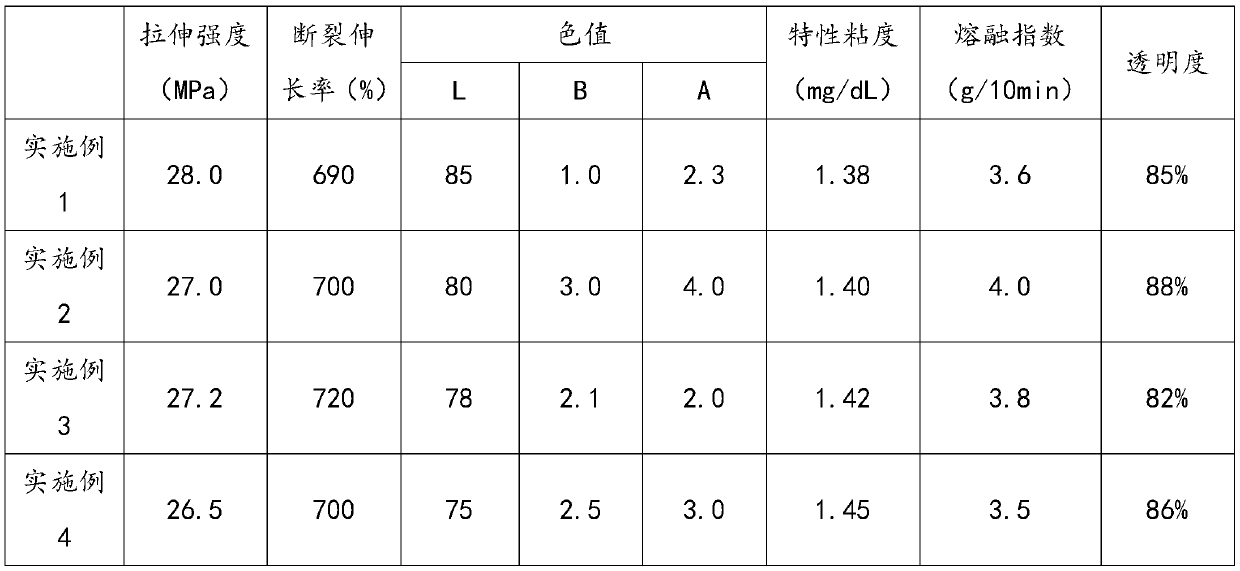

Examples

Embodiment 1

[0028] This embodiment provides a kind of preparation method of fully biodegradable copolyester, and specific preparation comprises the following steps:

[0029] (1) Terephthalic acid with a molar ratio of 1:1 and 1,4-butanediol are catalyzed by ethylene glycol titanium with a mass fraction of 0.3‰, under a nitrogen atmosphere and at a reaction temperature of 230°C for esterification The reaction is carried out for 2 hours, and the by-product water is continuously discharged during the reaction process. When the esterification rate reaches 99%, the reaction is terminated to obtain the esterified product A;

[0030] (2) Take adipic acid with a molar ratio of 1:1 and 1,4-butanediol to carry out esterification reaction under nitrogen atmosphere at a reaction temperature of 200°C, and react for 2 hours. During the reaction process, the by-product water is continuously discharged. When the esterification rate reaches more than 85%, the reaction is terminated to obtain esterified pr...

Embodiment 2

[0033] This embodiment provides a kind of preparation method of fully biodegradable copolyester, and specific preparation comprises the following steps:

[0034] (1) Terephthalic acid with a molar ratio of 1:2 and 1,4-butanediol were catalyzed by ethylene glycol titanium with a mass fraction of 1‰, under a nitrogen atmosphere and at a reaction temperature of 230°C for esterification The reaction is carried out for 2 hours, and the by-product water is continuously discharged during the reaction process. When the esterification rate reaches 99%, the reaction is terminated to obtain the esterified compound A;

[0035] (2) Take adipic acid with a molar ratio of 1:2 and 1,4-butanediol to carry out esterification reaction under nitrogen atmosphere at a reaction temperature of 200°C, and react for 2 hours. During the reaction process, the by-product water is continuously discharged. When the esterification rate reaches more than 85%, the reaction is terminated to obtain esterified pr...

Embodiment 3

[0038] This embodiment provides a kind of preparation method of fully biodegradable copolyester, and specific preparation comprises the following steps:

[0039] (1) Take isophthalic acid and 1,10-decanediol with a molar ratio of 1:1 under the catalysis of tetrapropyl titanate with a mass fraction of 1.5‰, under a nitrogen atmosphere and at a reaction temperature of 230°C Esterification reaction, reaction for 2 hours, the by-product water is continuously discharged during the reaction process, and when the esterification rate reaches 99%, the reaction is terminated to obtain esterified compound A;

[0040](2) Take adipic acid with a molar ratio of 1:1 and 1,10-decanediol to carry out esterification reaction under a nitrogen atmosphere at a reaction temperature of 200°C, and react for 2 hours, and the by-product water is continuously discharged during the reaction process. When the esterification rate reaches more than 85%, the reaction is terminated to obtain esterified produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com