Preparation method of halogen-free intrinsic flame-retardant waterborne polyurethane film

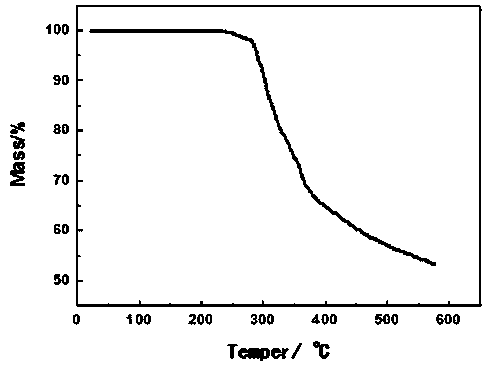

A polyurethane film and an essential technology, applied in the field of preparation of halogen-free intrinsically flame retardant water-based polyurethane film, can solve the problems of large amount of flame retardant filler, poor water washing resistance, uneven coating film, etc., and achieve good flame retardant performance, The effect of high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The preparation method of the halogen-free intrinsic flame-retardant water-based polyurethane film of the present embodiment, the steps are as follows:

[0018] 1. According to the number of parts by mass, add 17 parts of pentaerythritol into a three-necked flask with a reflux device and a tail gas treatment device, weigh 115 parts of phosphorus oxychloride, add it to the three-necked flask, turn on the magnetic stirring and condensing device, and start to heat up. When the temperature of the system reaches 60°C, react for 1 hour and then raise the temperature to 105°C, continue the reaction for 6 hours, then end the reaction, wash repeatedly with dichloromethane and absolute ethanol, filter with suction and dry to obtain a white powder, which is the intermediate product pentaerythritol bis Phosphate diphosphoryl chloride (PDD).

[0019] 2. According to the number of parts by mass, add 15 parts of PDD prepared in step 1 into a three-necked flask, and then add 150 parts ...

Embodiment 2

[0023] The preparation method of the halogen-free intrinsic flame-retardant water-based polyurethane film of the present embodiment, the steps are as follows:

[0024] 1. In parts by mass, add 25.5 parts of pentaerythritol into a three-necked flask with a reflux device and a tail gas treatment device, weigh 170 parts of phosphorus oxychloride, add it to the three-necked flask, turn on the magnetic stirring and condensing device, and start to heat up. When the temperature of the system reaches 60°C, react for 1.5 hours and then raise the temperature to 105°C, continue the reaction for 7 hours, then end the reaction, wash repeatedly with dichloromethane and absolute ethanol, filter with suction and dry to obtain a white powder, which is the intermediate product pentaerythritol Bisphosphonate diphosphoryl chloride (PDD).

[0025] 2. According to the number of parts by mass, add 30 parts of PDD prepared in step 1 into the three-necked flask, and then add 200 parts of chloroform, 2...

Embodiment 3

[0029] The preparation method of the halogen-free intrinsic flame-retardant water-based polyurethane film of the present embodiment, the steps are as follows:

[0030] 1. In parts by mass, add 34 parts of pentaerythritol into a three-necked flask with a reflux device and a tail gas treatment device, weigh 230 parts of phosphorus oxychloride, add it to the three-necked flask, turn on the magnetic stirring and condensing device, and start to heat up. When the temperature of the system reaches 60°C, react for 2 hours and then raise the temperature to 105°C, continue the reaction for 8 hours and end the reaction, wash repeatedly with dichloromethane and absolute ethanol, filter with suction and dry to obtain a white powder, which is the intermediate product pentaerythritol bis Phosphate diphosphoryl chloride (PDD).

[0031] 2. According to the number of parts by mass, add 45 parts of PDD prepared in step 1 into the three-necked flask, then add 250 parts of chloroform, 33 parts of di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com