Copper-impregnated carbon slider and preparation method thereof

A carbon sliding plate and copper immersion technology, applied in the field of material processing, can solve the problems of increasing resistivity, increased surface friction, poor wettability, etc., and achieve the effect of improving wettability, good mechanical properties and electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

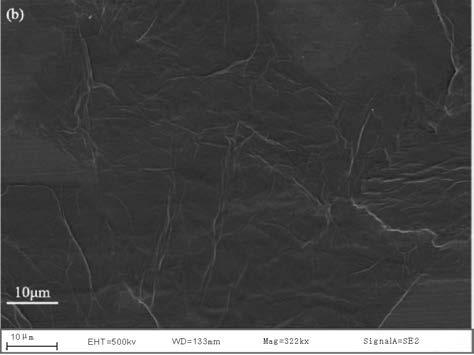

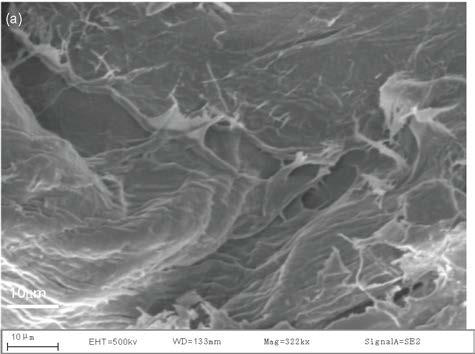

Image

Examples

preparation example Construction

[0069] The invention discloses a method for preparing a copper-impregnated carbon sliding plate, which comprises the following steps:

[0070] (1) Take the basic raw materials for preparing copper-impregnated carbon slides, add them to the kneading equipment according to the weight ratio, and mix them evenly in the kneading equipment to obtain a mixture; the basic raw materials include pitch coke, petroleum coke, flake graphite, carbon fiber, binder and Porogen;

[0071] (2) Compress the mixture into a shape, heat-preserve and dry it after setting; obtain a dry billet; then perform high-pressure molding on the dry billet in a mold to obtain a molded billet;

[0072] (3) Carry out high-temperature sintering treatment on the forming blank, gasify the pore-forming agent in the forming blank to form pores in the forming blank, and obtain the basic carbon sliding plate;

[0073] (4) Preparation of wetting aid: Disperse magnesium aluminum silicate powder and iron boride powder in w...

Embodiment 1

[0083] Example 1: Preparation of Basic Carbon Sliding Plate

[0084] The basic raw material composition of the basic carbon skateboard:

[0085] 25 parts of pitch coke; 10 parts of petroleum coke; 18 parts of flake graphite;

[0086] 2 parts of carbon fiber; 13 parts of phenolic resin; 6 parts of 250 mesh bamboo charcoal powder.

[0087] (1) Take the basic raw materials and add them to the kneading equipment, and mix them evenly in the kneading equipment to obtain the mixture;

[0088] (2) Press and shape the mixture. Roller extruder can be used for compacting. After being extruded into sheets, put it into a cylinder or square cylinder and use a press for compaction. The compaction operating pressure is 1atm, that is, 1 piece atmospheric pressure. After setting the shape, heat-preserve and dry at 80°C; obtain a dry blank;

[0089] Apply external release agent polyvinyl alcohol in the mould, then put the dry blank into the mold and carry out high-pressure molding under a pr...

Embodiment 2

[0091] Embodiment 2: Preparation of copper-impregnated carbon slide plate

[0092] (1) Preparation of wetting aid: disperse 90g of iron boride powder and 10g of magnesium aluminum silicate powder into 1000g of water to form a mixed solution with good fluidity, which is the wetting aid dispersion;

[0093] (2) Put the basic carbon slide into the wetting aid dispersion, let the wetting aid dispersion enter the pores of the base carbon slide under high pressure conditions of 2 atm, take out the base carbon slide after immersion for 3 minutes and clean the surface of the base carbon slide, Clean the wetting aid dispersion on the surface, and then vacuum sinter at 2000°C to remove the moisture in the pores, and let the wetting aid melt and disperse to the surface of the pores;

[0094] (3) Repeat step (2) 3 times; get a carbon skateboard;

[0095] (4) Put the carbon slide plate into the copper immersion equipment, first vacuum the gas in the pores of the carbon slide plate, submer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com