Zr-MOFs/graphene oxide porous composite material as well as preparation method and application thereof

A porous composite material and graphene technology, applied in the field of porous composite materials, can solve the problems of affecting the hydrogen storage performance of the material, unable to meet the application requirements, less microporous structure, etc., and achieve regular product phase structure, high yield, and improve defects. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Graphene oxide content is the preparation method of the Zr-MOFs / graphene oxide porous composite material of 2wt%, concrete operation steps are as follows:

[0041] Step 1) Add 0.00798mg graphene oxide, 0.233mg zirconium tetrachloride, 0.166mg terephthalic acid, 3.8mL formic acid (the ratio of zirconium tetrachloride to formic acid is 100:1) into 20mL DMF, ultrasonic , followed by hydrothermal reaction at 120°C for 24 hours, after filtration and washing, the unactivated Zr-MOFs / graphene oxide porous composite material can be obtained;

[0042] Step 2) Soak the unactivated Zr-MOFs / graphene oxide porous composite obtained in step 1) in dichloromethane for three days, change the dichloromethane every 24h, and finally dry it at 120°C for 6h to obtain Zr -MOFs / graphene oxide porous composites;

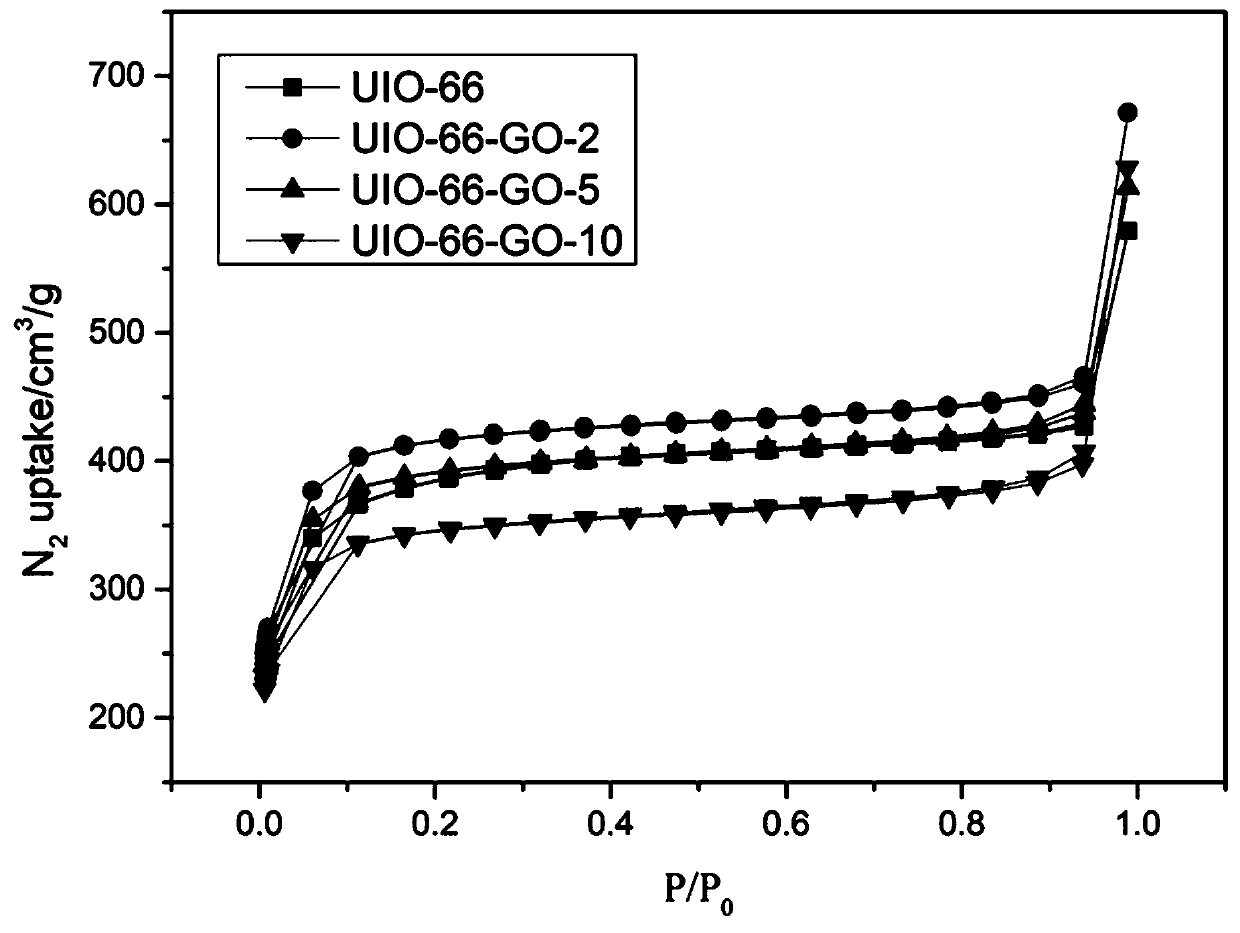

[0043] The Zr-MOFs / graphene oxide porous composite material prepared in Example 1 was tested for low-temperature nitrogen isothermal adsorption performance. The test conditions were ...

Embodiment 2

[0053] Graphene oxide content is Zr-MOFs / graphene oxide porous composite material of 5wt% of Zr-MOFs, its preparation method does not specify the step and embodiment 1 (graphene oxide content is 2wt% Zr-MOFs / graphene oxide The preparation method of the graphene porous composite material) is the same, the difference is that the mass of graphene oxide weighed in the step 1) is 0.01995 mg.

[0054] The characterization test methods are the same as those in Example 1 above.

[0055] The Zr-MOFs / graphene oxide porous composite material prepared in Example 2 was subjected to a low-temperature nitrogen isothermal adsorption performance test. Test results such as figure 1 As shown in UIO-66-GO-5, the Zr-MOFs / graphene oxide porous composite has a specific surface area of 1502 m 2 / g.

[0056] The Zr-MOFs / graphene oxide porous composite material prepared in Example 2 was subjected to a low-temperature nitrogen isothermal adsorption performance test. Test results such as figure 2...

Embodiment 3

[0061] Graphene oxide content is the preparation method of the Zr-MOFs / graphene oxide porous composite material of 10wt%, concrete operation steps are as follows:

[0062] The steps not specifically described are the same as in Example 1 (preparation method of Zr-MOFs / graphene oxide porous composite material with a graphene oxide content of 2wt%), except that the graphene oxide weighed in step 1) The mass is 0.0399 mg.

[0063] The characterization test methods are the same as those in Example 1 above.

[0064] The Zr-MOFs / graphene oxide porous composite material prepared in Example 3 was subjected to a low-temperature nitrogen isothermal adsorption performance test. Test results such as figure 1 As shown in UIO-66-GO-10, the Zr-MOFs / graphene oxide porous composite has a specific surface area of 1326 m 2 / g.

[0065] The Zr-MOFs / graphene oxide porous composite material prepared in Example 3 was subjected to a low-temperature nitrogen isothermal adsorption performance tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com