Stable meal delivery heat insulation foam box

A technology of foam box and food delivery, which is applied in the direction of preventing mechanical damage, such as containers, transportation and packaging, and unloading devices. Stability, easy to take meals, and avoid meal leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

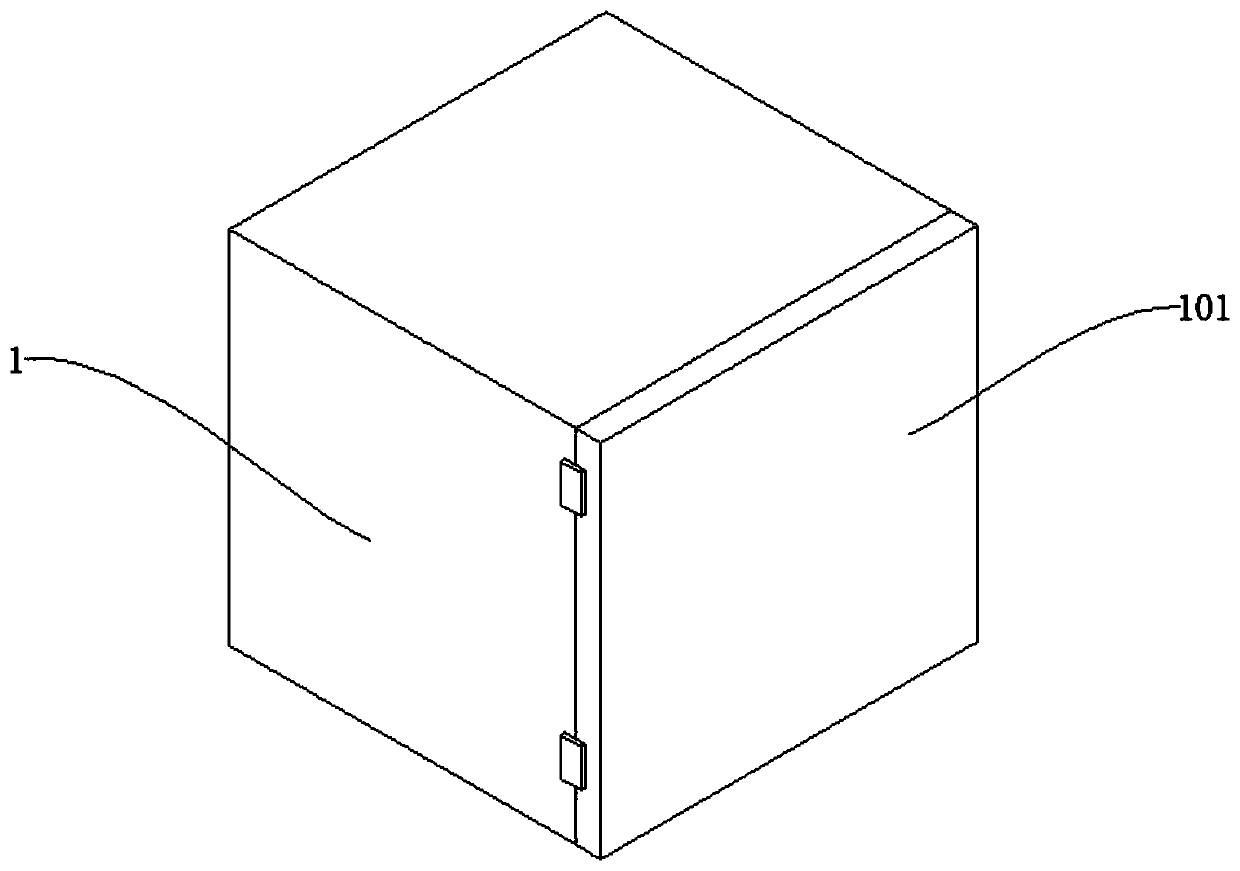

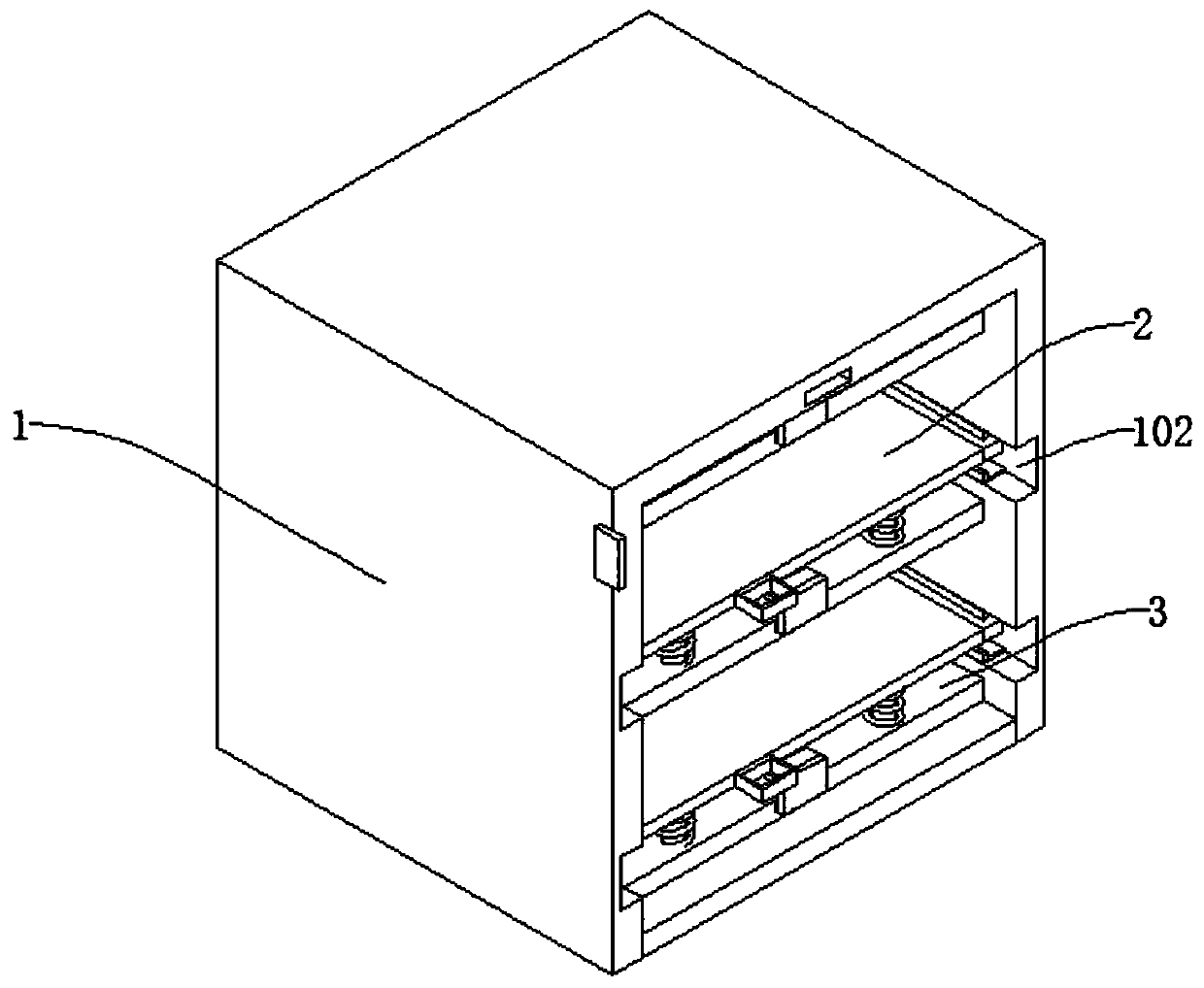

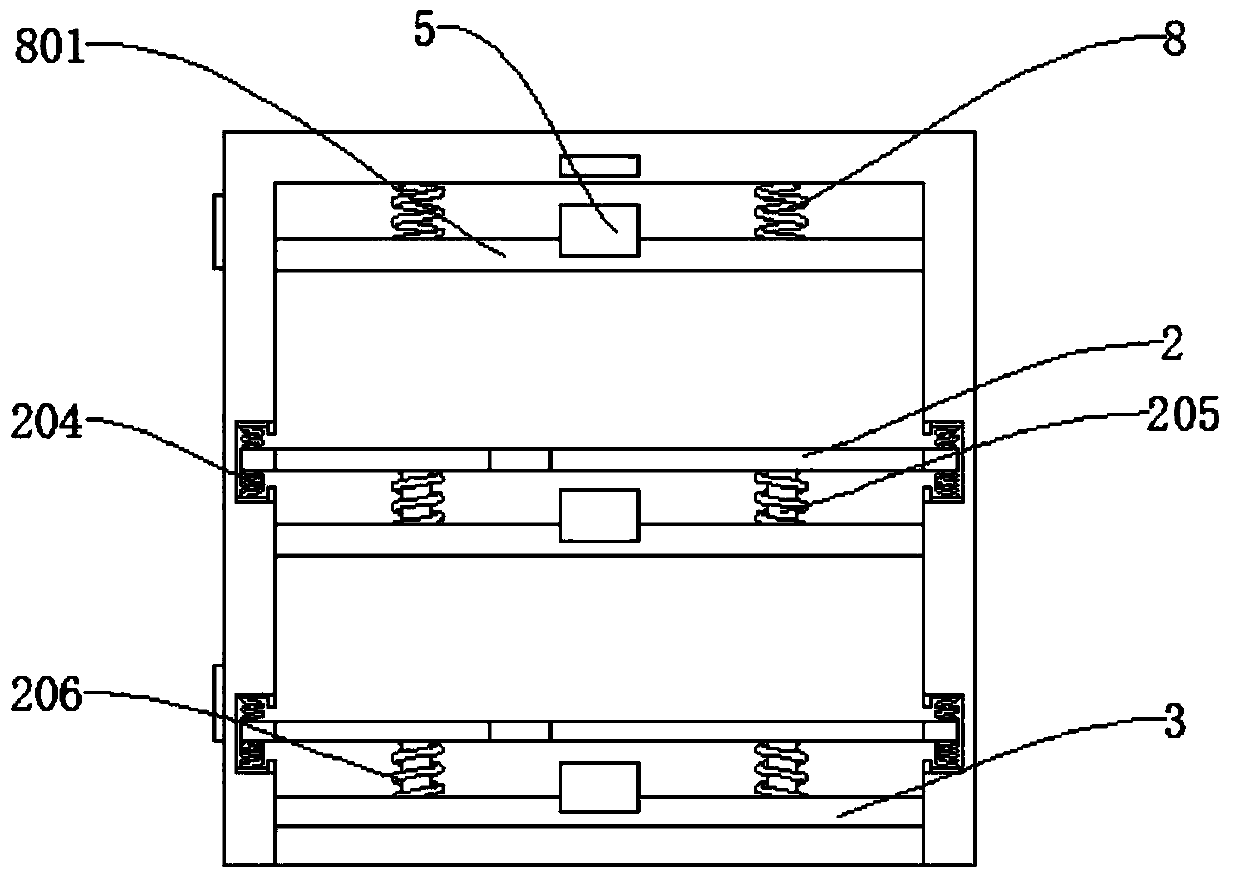

[0033] refer to Figure 1-7 , a stable thermal insulation foam box for food delivery, including a box body 1 and a box cover 101, the box body 1 and the box cover 101 are connected by a hinge, and a first groove 102 is dug on the inner wall of the box body 1, and the first groove 102 The support plate 2 is connected inside, the first elastic member 204 is connected to the top wall and the bottom wall of the support plate 2, and the end of the first elastic member 204 away from the support plate 2 is respectively connected to the first slide plate 201 and the second slide plate 202. A sliding plate 201 and a second sliding plate 202 are slidably connected to the inner wall of the first groove 102 , and the inner wall of the first groove 102 is connected with a stopper 103 matching the first sliding plate 201 and the second sliding plate 202 .

[0034] refer to Figure 2-7 The first connecting rod 203 is connected to the bottom wall of the first sliding plate 201, and the end o...

Embodiment 2

[0040] refer to Figure 6-7 , is basically the same as that of Embodiment 1, furthermore, a third groove 501 is drilled on the outer wall of the first pressing plate 3 and the second pressing plate 801, and a third elastic member 502 is connected to the inner wall of the third groove 501, and the third The end of the elastic member 502 away from the inner wall of the third groove 501 is connected with a block 5; Compression is carried out so that the first pressing plate 3 is separated from the meals, so that the support plate 2 is pulled out of the casing 1, so that it is convenient to take the meals. Under the action of the elastic force of the second elastic member 206, it moves downward, and at the same time, through the third elastic member 502 provided, the clamping block 5 will be pulled back to the inside of the first pressing plate 3, thereby facilitating the first pressing plate 3 to continue to support the supporting plate. 2. The meals placed on the top play the r...

Embodiment 3

[0042] refer to Figure 7 , which is basically the same as in Example 1, furthermore, with reference to Figure 1-2 A fourth groove 701 is dug on the outer wall of the support plate 2, a fourth elastic member 7 is connected to the inner wall of the fourth groove 701, and the end of the fourth elastic member 7 away from the inner wall of the fourth groove 701 is connected to the inner wall of the box body 1.

[0043] refer to Figure 4-5 , a handle 4 is also connected to the outer wall of the support plate 2 .

[0044] By pulling the handle 4, the support plate 2 is then driven to move outside the box body 1, and then the first pressing plate 3 and the support plate 2 are pulled out of the box body 1, thereby facilitating the meal delivery personnel to take the meal. The fourth elastic member 7, under the action of the elastic force of the fourth elastic member 7, will pull the supporting plate 2 and the first pressing plate 3 back to the inside of the box body 1, which is ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com